Gas water heater and control method and system thereof

A technology for gas water heaters and control systems, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as changes, differences in gas calorific value, and increased costs such as manpower, material resources, and financial resources, so as to avoid flameout and improve versatility. , the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

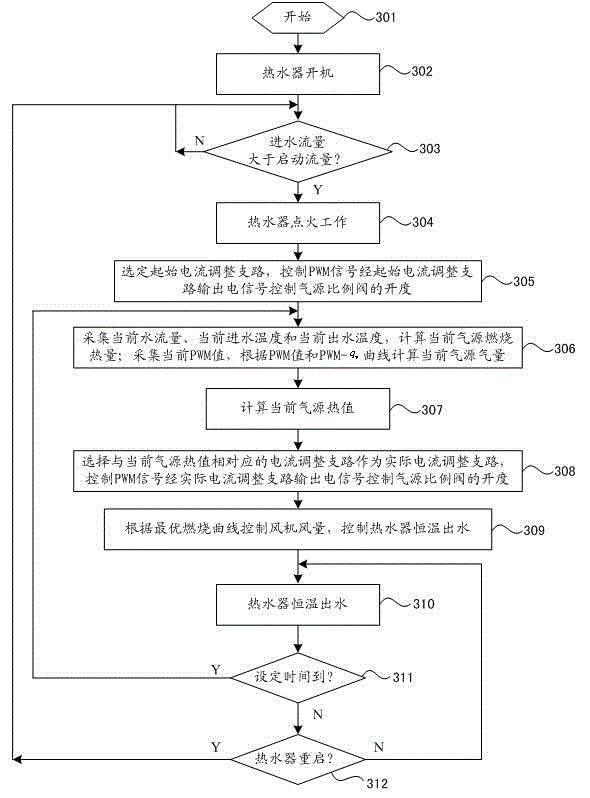

[0035] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] First, briefly explain the design starting point of the present invention:

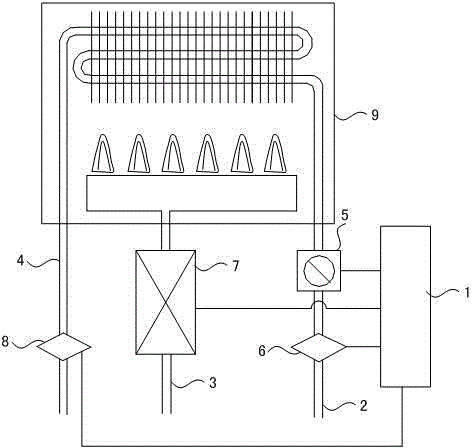

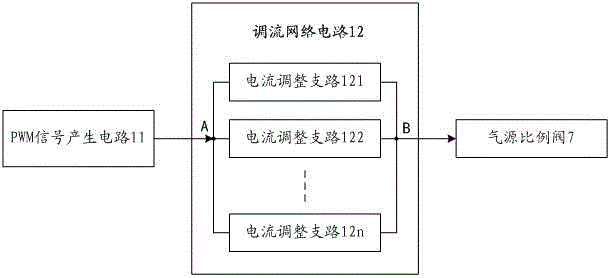

[0037] Each gas water heater corresponds to a unique optimal combustion curve, which reflects the ratio relationship between gas combustion heat and fan air volume. If the water heater burns according to the ratio of the combustion heat determined by the optimal combustion curve to the air volume of the fan, the gas efficiency will be the highest, and the exhaust gas content will be the least. The combustion heat of gas is related to the amount of gas and the calorific value of combustion. The amount of gas depends on the opening of the gas proportional valve, and the opening of the gas proportional valve is controlled by the PWM signal. Therefore, the prior art usually The optimal combustion curve can also be regarded as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com