Method for separating and analyzing milrinone

A technology of separation analysis and milrinone, which is applied in the field of analytical chemistry, can solve the problems of unstable baseline, low theoretical plate number, and small number of impurities, etc., and achieve the effect of stable baseline, high theoretical plate number and quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0217] Sample Preparation:

[0218] Take 2.7 g of potassium dihydrogen phosphate, add 1000 ml of water to dissolve it, add 3.0 ml of triethylamine to it, adjust the pH value to 6.0 with 10% phosphoric acid solution, and obtain the aqueous phase. The aqueous phase and methanol were prepared as the mobile phase at a volume ratio of 80:20.

[0219] Accurately weigh about 10 mg of milrinone, add an appropriate amount of methanol, and ultrasonicate for 1 minute at room temperature. After the milrinone is completely dissolved, dilute it with the mobile phase to form a solution with a concentration of 1 mg / ml of milrinone as the test solution. .

[0220] Accurately measure the test solution, and dilute it with the mobile phase to a solution with a concentration of milrinone of 1 μg / ml, as a contrast solution.

[0221] Accurately weigh an appropriate amount of milrinone-related substance A reference substance, mix it with an appropriate amount of methanol-water (volume ratio of 80:2...

Embodiment 2

[0233] Sample preparation, chromatographic conditions and determination methods were all carried out according to the method of Example 1, except that the pH of the mobile phase was 5.8.

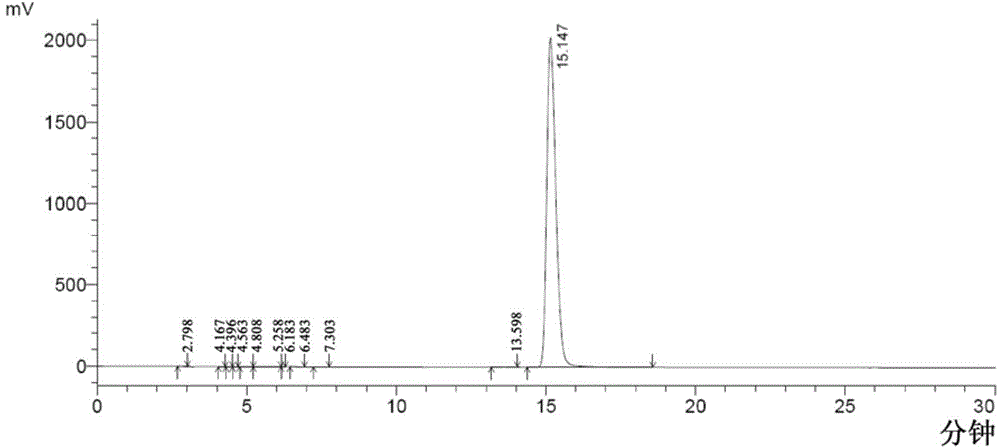

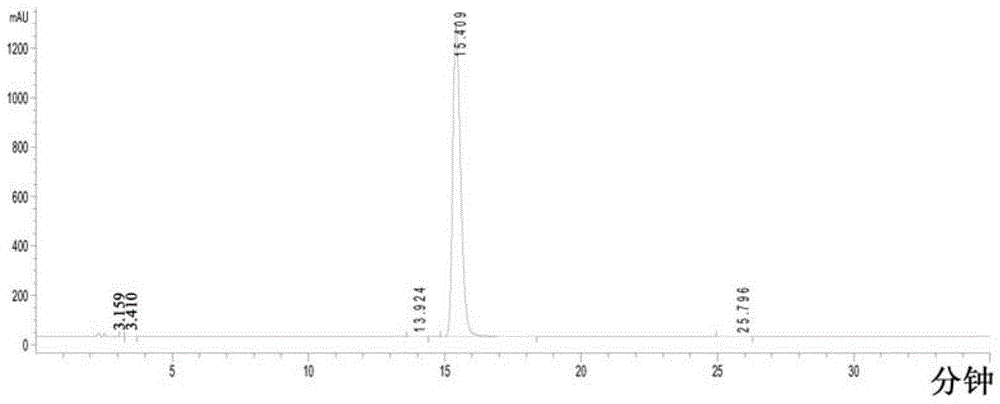

[0234] The results of testing the test solution are as follows: Figure 23 As shown in the figure, it can be seen that under the conditions of the present invention, the main peak of milrinone can be effectively separated from each impurity, the chromatographic peak shape of milrinone is better, and the baseline is relatively stable, and the related substances in milrinone can be accurately measured .

Embodiment 3

[0236] Sample preparation, chromatographic conditions and determination methods were all carried out according to the method of Example 1, except that the pH of the mobile phase was 6.2.

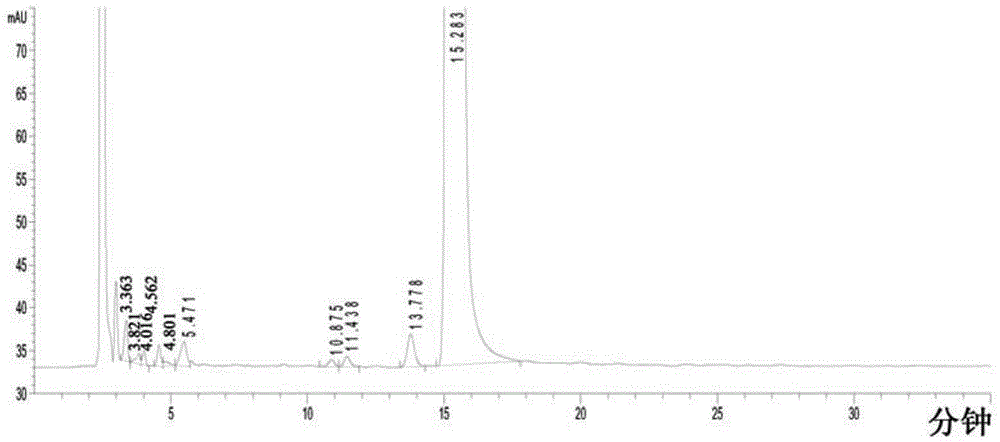

[0237] The results of testing the test solution are as follows: Figure 24 As shown in the figure, it can be seen that under the conditions of the present invention, the main peak of milrinone can be effectively separated from each impurity, the chromatographic peak shape of milrinone is better, and the baseline is relatively stable, and the related substances in milrinone can be accurately measured .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com