Method for manufacturing terminal-strip-equipped electronic component and terminal-strip-equipped electronic component

A technology for electronic components and manufacturing methods, which is applied in capacitor manufacturing, electrical components, and fixed capacitor dielectrics, etc., can solve problems such as cracks in electronic components, terminal electrode peeling, etc. The effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, one embodiment according to the present invention will be specifically described with reference to the drawings.

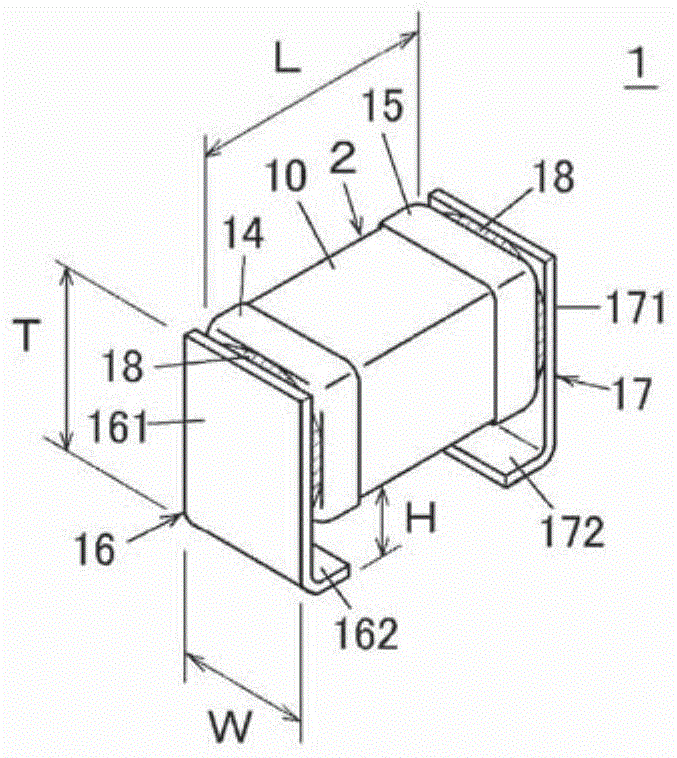

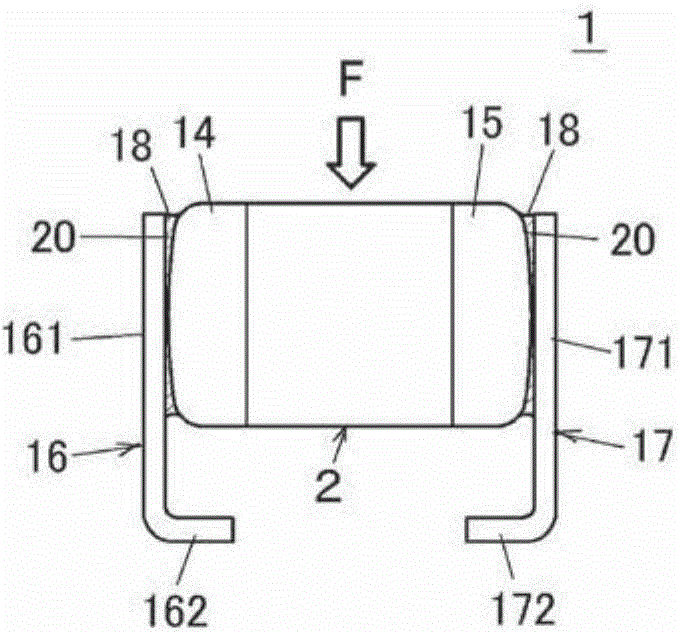

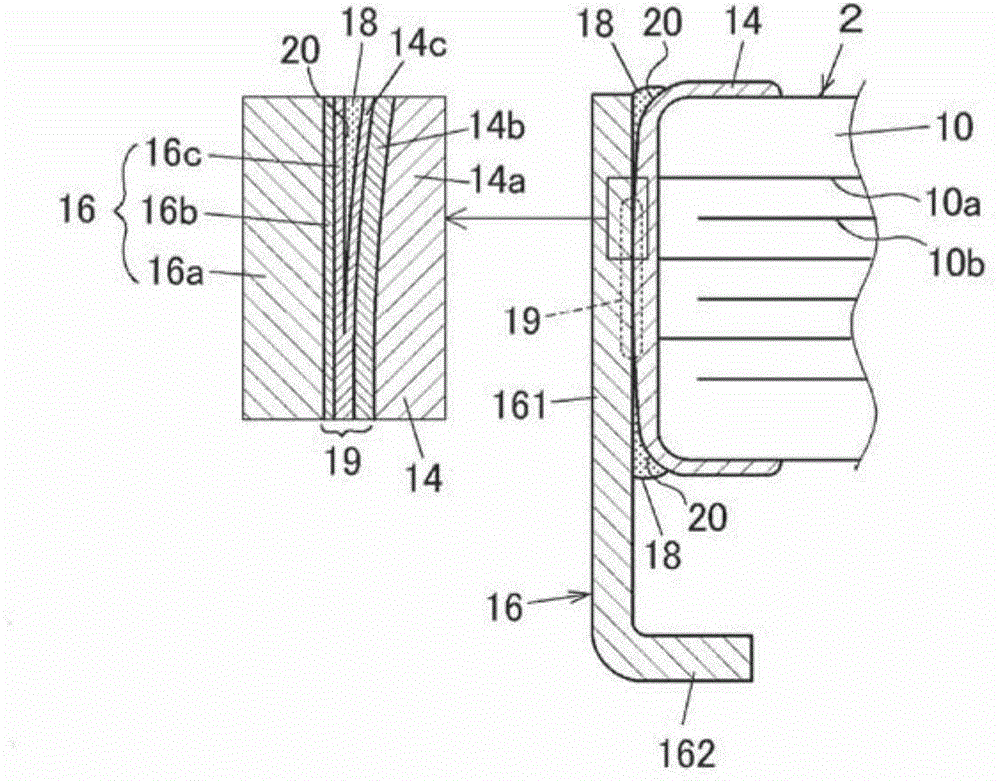

[0042] Such as figure 1 and figure 2 As shown, an electronic component 1 with a terminal board mounted thereon as an embodiment of the present invention includes an electronic chip component 2 and a pair of terminal boards 16 , 17 . The electronic component 2 includes a substantially rectangular parallelepiped ceramic body 10 . The ceramic body 10 includes, for example, a plurality of laminated ceramic layers and a plurality of internal electrodes 10a, 10b arranged between the ceramic layers. Since the structures and materials of the ceramic layers and internal electrodes are well known, description thereof will be omitted. In addition, as the electronic chip component 2, as long as it is a chip component with terminal electrodes formed on both end faces, for example, it may be a multilayer ceramic capacitor, a chip inductor, a chip thermist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com