Sludge dewatering equipment

A technology of sludge dewatering machine and dewatering chamber, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of large processing cycle, large area and high operating cost, and reduce energy consumption. , The effect of reducing electricity consumption and reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

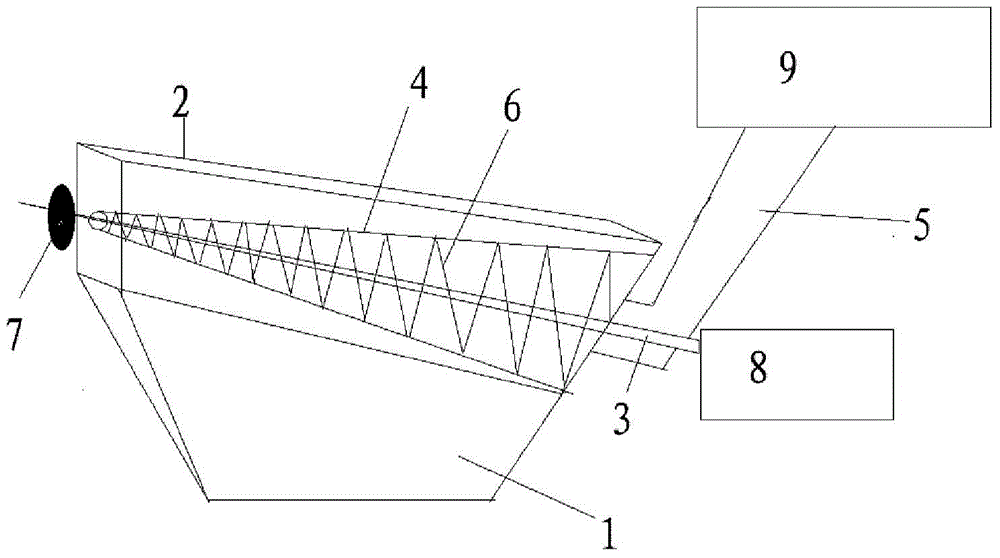

[0020] figure 1 It is a specific embodiment of the sludge dewatering machine of the present invention. It includes (1) a filtrate recovery tank, (2) a casing, (3) a rotating shaft with a spiral blade, (4) a dehydration cavity, (5) a feeding pipe, (6) a spiral blade, and (7) a mud discharge port , (8) baffle plate and (9); wherein the rotating shaft (3) runs through the dehydration chamber (4), one end of the rotating shaft (3) is connected to the motor, and the other end passes through the mud discharge port (7) on the casing ) is connected to the baffle plate (8), the spiral blades (6) on the rotating shaft (3) are continuous, the spiral blades (6) spirally rise from the motor end to the mud discharge port end along the rotating shaft, and the spiral blades (6) The radius and the distance between the spiral blades (6) and the wall of the dehydration chamber (4) are continuously reduced along the ascending direction, and the distance between the spiral blades (6) and the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com