An anti-blocking structured packing

A technology of structured packing and packing body, applied in chemical/physical/physical chemical process, chemical instrument and method, chemical/physical process, etc., can solve the problems of poor anti-blocking ability, blockage of benzene washing tower, large gas flow rate, etc. Achieve the effects of high gas-liquid mass transfer efficiency, enhanced sufficiency, and good uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment and accompanying drawing thereof, the present invention will be further described:

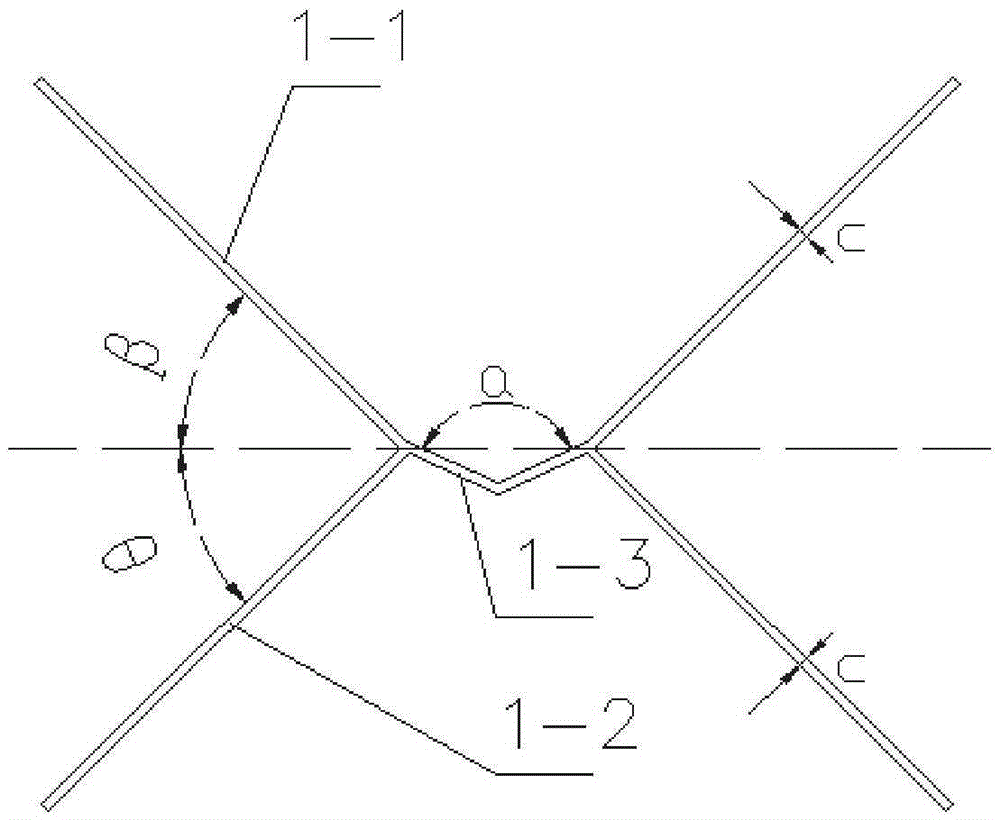

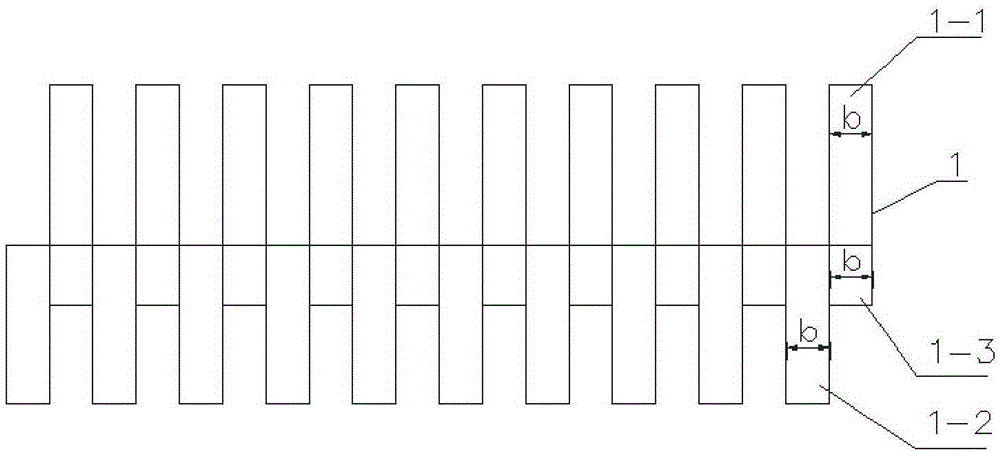

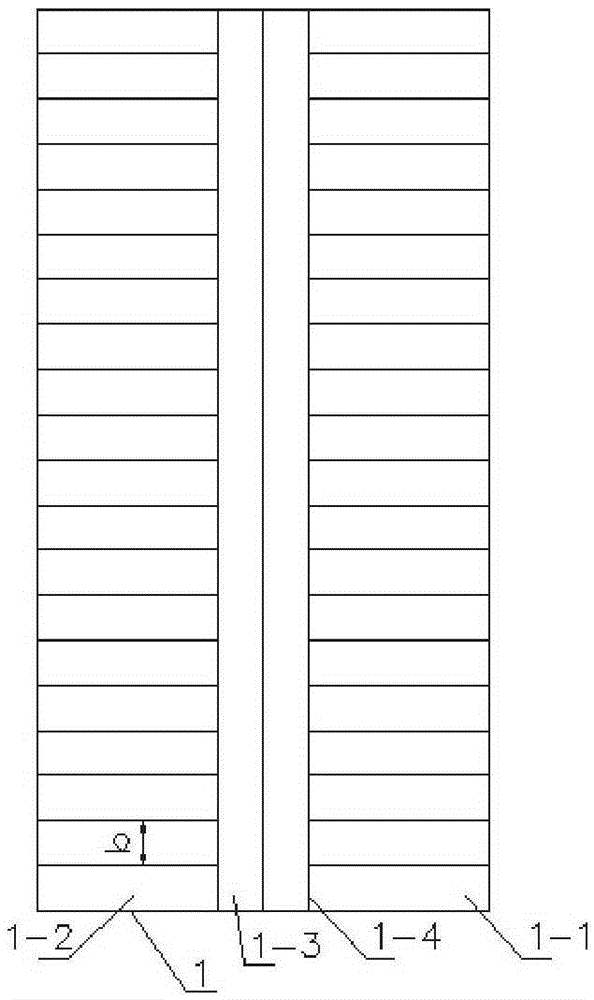

[0019] The packing unit for anti-blocking structured packing provided in this embodiment includes a pair of upper fins 1-1, a pair of lower fins 1-2, and a liquid sump 1-3; the size and elevation angle of the pair of upper fins β are all the same, the size and inclination angle θ of a pair of lower wings are also the same, β=θ=30°, the roots of the upper and lower wings located on the same side of the sump are alternately connected to the edge of the sump, the sump The cross-section of the tank body is V-shaped, and when it is placed horizontally, the V-shaped opening faces upward; the projections of the outer edge of the upper wing and the outer edge of the lower wing on the plane passing the edge of the groove are equal to the distance from the edge of the liquid collection tank. The included angle α of the V-shaped section of the sump 1-3 is 120°....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com