Catalyst of methacrylaldehyde and methacrylic acid, as well as preparation method of catalyst for synthesizing methacrylaldehyde and methacrylic acid

A technology of methacrolein and methacrylic acid, applied in the preparation of carbon-based compounds, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of low catalyst activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

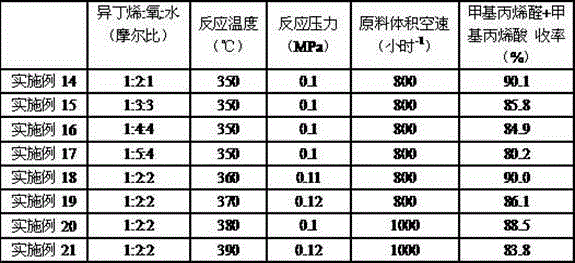

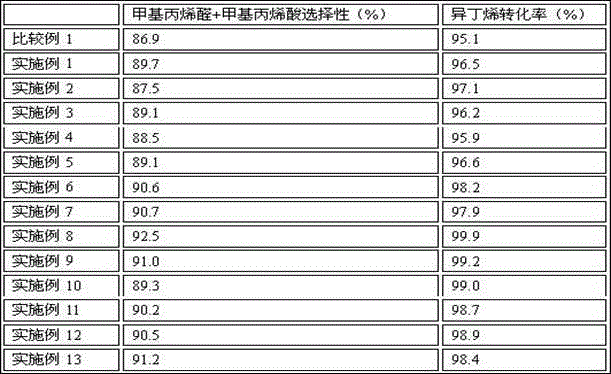

Examples

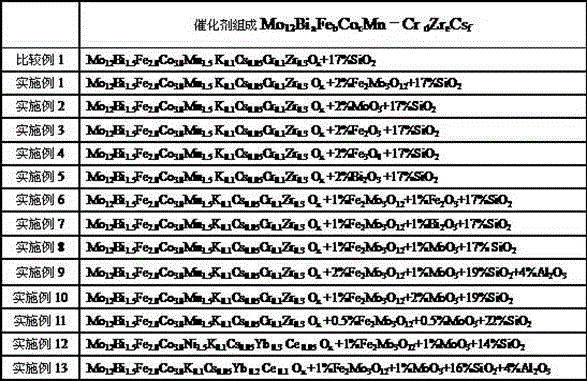

Embodiment 1

[0028] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 grams of water at 70°C, stirred to dissolve it completely, and 63.2 grams of silica sol with a concentration of 40wt% was added to form mixture I.

[0029] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 20 grams of water at 70°C, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 25.1 grams concentration is 50wt% Mn(NO 3 ) 2 Aqueous solution, 0.32 g KNO 3 and 0.46 g CsNO 3 , 0.47 g Cr 2 o 3 , 6.1 grams of Zr(NO 3 ) 4 ·5H 2 O was stirred and dissolved to form mixture II.

[0030] Add mixture II to mixture I with stirring, add 18.6 g of Fe after mixing 2 Mo 3 o 12 , add ammonia water, adjust the pH to 7, and stir and mature at 80°C for 2 hours. The slurry is evaporated at 100°C to a solid content of 80wt%, extruded to obtain a cylindrical object of φ3.5x3.5mm, and then roasted at high temperature to obtain For the finished catalyst, the calcination temperature is 4...

Embodiment 2

[0032] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 grams of water at 70°C, stirred to dissolve it completely, and 63.2 grams of silica sol with a concentration of 40wt% was added to form mixture I.

[0033] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 20 grams of 70°C hot water, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H 2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 25.1 grams concentration is 50wt% Mn(NO 3 ) 2 Aqueous solution, 0.47 g Cr 2 o 3 , 6.1 grams of Zr(NO 3 ) 4 ·5H 2 O. 0.32 g KNO 3、 0.46 g CsNO 3 Mixture II was prepared after stirring to dissolve.

[0034] Add mixture II to mixture I under stirring, mix well and add 18.6 g of MoO 3 , add ammonia water, adjust the pH to 7, and stir and mature at 80°C for 2 hours. The slurry is evaporated at 100°C to a solid content of 80wt%, extruded to obtain a cylindrical object of φ3.5x3.5mm, and then roasted at high temperature to obtain For the finished catalyst, the calcination temperature is 490° ...

Embodiment 3

[0036] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 grams of water at 70°C, stirred to dissolve it completely, and 63.2 grams of silica sol with a concentration of 40wt% was added to form mixture I.

[0037] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 20 grams of 70°C hot water, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H 2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 25.1 grams concentration is 50wt% Mn(NO 3 ) 2 Aqueous solution, 0.47 g Cr 2 o 3 , 6.1 grams of Zr(NO 3 ) 4 ·5H 2 O. 0.32 g KNO 3 , 0.46 g CsNO 3 Mixture II was prepared after stirring to dissolve.

[0038] Add mixture II to mixture I under stirring, add 18.6 g of Fe after stirring 2 o 3 , add ammonia water, adjust the pH to 7, and stir and mature at 80°C for 2 hours. The slurry is evaporated at 100°C to a solid content of 80wt%, extruded to obtain a cylindrical object of φ3.5x3.5mm, and then roasted at high temperature to obtain For the finished catalyst, the calcination temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com