Allyl acetate catalyst and preparation method of allyl acetate catalyst

A technology of allyl acetate and catalyst, which can be used in catalyst activation/preparation, carboxylate preparation, chemical instruments and methods, etc., and can solve the problems of low activity and selectivity of allyl acetate catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

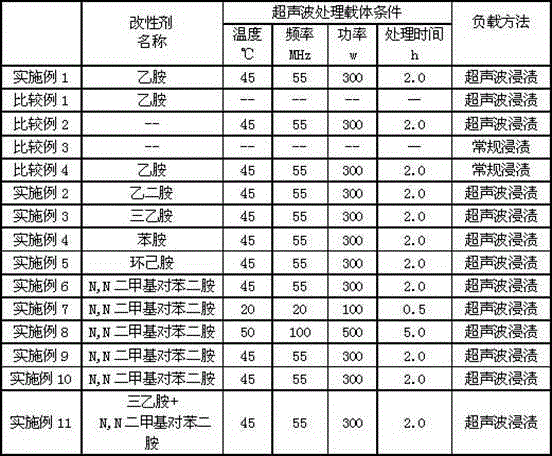

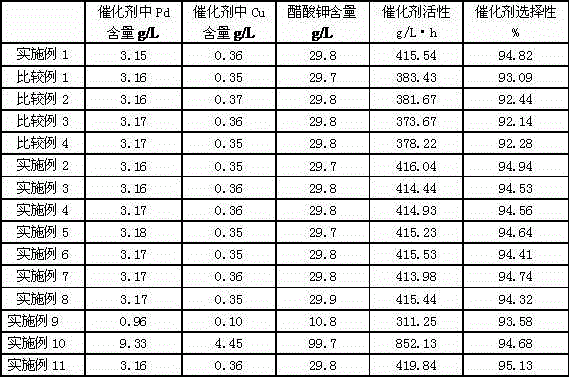

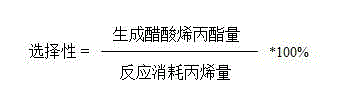

Examples

Embodiment 1

[0029] Preparation of carrier: Spray 350ml of 20g / L ethylamine aqueous solution evenly on 1.1L spherical SiO2 with a diameter of 5.6mm 2 On the carrier, obtain the carrier precursor A, then fix the beaker containing the carrier precursor A in a water-filled ultrasonic instrument, heat the water temperature to 45°C, adjust the ultrasonic frequency to 55MHz, and the power to 300w to maintain the water temperature and ultrasonic frequency vibration The carrier (X) was obtained by treating at low temperature for 2.0 h, then calcining at 500° C. for 5.0 h, and drying.

[0030] Catalyst preparation: pH 1.05, containing 3.50gPd and 0.40gCu, aqueous solution of chloropalladium acid and copper chloride was prepared with sodium bicarbonate pH adjuster and water as a solvent to obtain 590ml of impregnating solution. Fix the beaker with the carrier (X) in the ultrasonic instrument filled with water, heat the water temperature to 40°C, adjust the ultrasonic frequency to 35MHz, and the pow...

Embodiment 2

[0056] Preparation of carrier: Spray 350ml of 20g / L ethylenediamine aqueous solution evenly on 1.1L spherical SiO2 with a diameter of 5.6mm 2 On the carrier, obtain the carrier precursor A, then fix the beaker containing the carrier precursor A in a water-filled ultrasonic instrument, heat the water temperature to 45°C, adjust the ultrasonic frequency to 55MHz, and the power to 300w to maintain the water temperature and ultrasonic frequency vibration The carrier (X) was obtained by treating at low temperature for 2.0 h, then calcining at 500° C. for 5.0 h, and drying.

[0057] Catalyst preparation: pH 1.05, containing 3.50gPd and 0.40gCu, aqueous solution of chloropalladium acid and copper chloride was prepared with sodium bicarbonate pH adjuster and water as a solvent to obtain 590ml of impregnating solution. Fix the beaker with the carrier (X) in the ultrasonic instrument filled with water, heat the water temperature to 40°C, adjust the ultrasonic frequency to 35MHz, and the...

Embodiment 3

[0060] Preparation of carrier: Spray 350ml of 20g / L triethylamine ethanol solution evenly on 1.1L spherical SiO2 with a diameter of 5.6mm 2 On the carrier, obtain the carrier precursor A, then fix the beaker containing the carrier precursor A in a water-filled ultrasonic instrument, heat the water temperature to 45°C, adjust the ultrasonic frequency to 55MHz, and the power to 300w to maintain the water temperature and ultrasonic frequency vibration The carrier (X) was obtained by treating at low temperature for 2.0 h, then calcining at 500° C. for 5.0 h, and drying.

[0061]Catalyst preparation: pH 1.05, containing 3.50gPd and 0.40gCu, aqueous solution of chloropalladium acid and copper chloride was prepared with sodium bicarbonate pH adjuster and water as a solvent to obtain 590ml of impregnating solution. Fix the beaker with the carrier (X) in the ultrasonic instrument filled with water, heat the water temperature to 40°C, adjust the ultrasonic frequency to 35MHz, and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com