Allyl acetate catalyst and application thereof

A technology of allyl acetate and catalyst, applied in physical/chemical process catalyst, carboxylate preparation, organic compound/hydride/coordination complex catalyst, etc. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

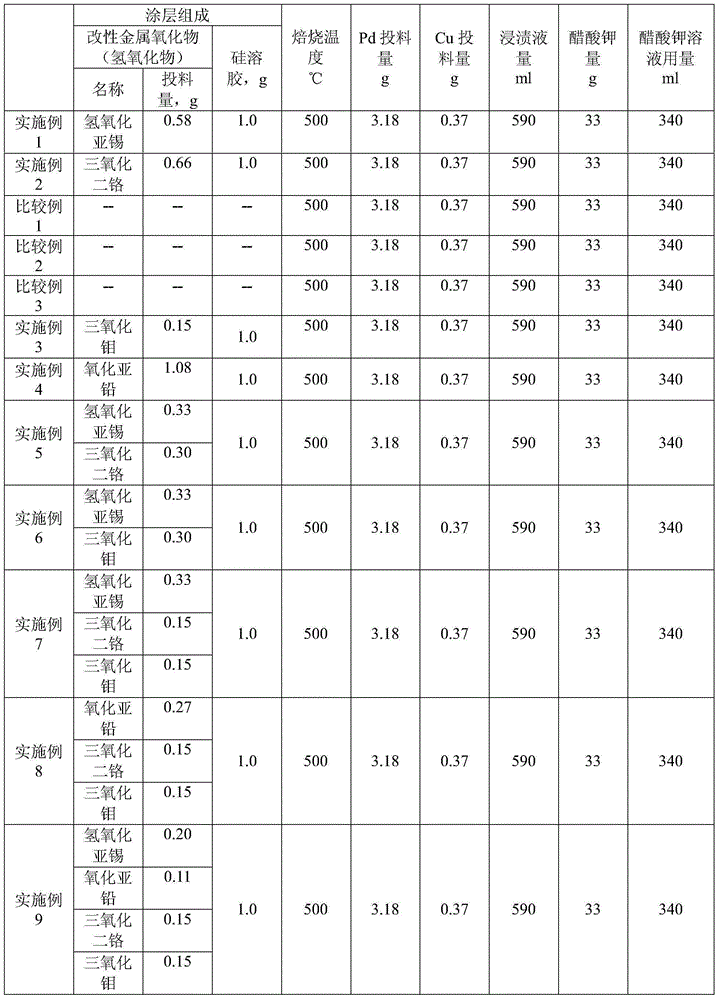

Embodiment 1

[0037] Preparation of carrier: 0.58g of stannous hydroxide (Sn(OH) 2 ) powder and 1.0g of silica sol are fully mixed to obtain a coating solution, and the coating solution is evenly sprayed on 1.0L of spherical SiO with a diameter of 5.6mm 2 , dried at 100°C, and calcined at 500°C in a muffle furnace to obtain the catalyst carrier. The Sn content in the carrier was determined by ICP to be 0.45 g / L.

[0038] Catalyst preparation:

[0039] (1) Use sodium bicarbonate pH regulator and water as a solvent to prepare a pH of 1.06, containing 3.18gPd and 0.37gCu of chloropalladic acid and copper chloride aqueous solution to obtain 590ml of impregnating solution. impregnating it on the catalyst carrier in a rotating pan to obtain catalyst precursor I;

[0040] (2) After drying at 80°C, 105ml contains 21.5g Na 2 SiO 3 9H 2 The solution of O was fully mixed, and aged for 24h to obtain catalyst precursor II;

[0041] (3) With a solubility of 10% (in N 2 h 4 ·H 2 (2 in weight ratio...

Embodiment 2

[0049] Preparation of carrier: 0.66g of chromium trioxide (Cr 2 o 3 ) powder and 1.0g of silica sol are fully mixed to obtain a coating solution, and the coating solution is evenly sprayed on 1.0L of spherical SiO with a diameter of 5.6mm 2 , dried at 100°C, and calcined at 500°C in a muffle furnace to obtain the catalyst carrier. The Cr content in the carrier was determined to be 0.45 g / L by ICP.

[0050] Catalyst preparation:

[0051] (1) Use sodium bicarbonate pH regulator and water as a solvent to prepare a pH of 1.06, containing 3.18gPd and 0.37gCu of chloropalladic acid and copper chloride aqueous solution to obtain 590ml of impregnating solution. impregnating it on the catalyst carrier in a rotating pan to obtain catalyst precursor I;

[0052] (2) After drying at 80°C, 105ml contains 21.5g Na 2 SiO 3 9H 2 The solution of O was fully mixed, and aged for 24h to obtain catalyst precursor II;

[0053] (3) With a solubility of 10% (in N 2 h 4 ·H 2 (2 in weight rat...

Embodiment 3

[0100] Preparation of carrier: 0.15g of molybdenum trioxide (MoO 3 ) powder and 1.0g of silica sol are fully mixed to obtain a coating solution, and the coating solution is evenly sprayed on 1.0L of spherical SiO with a diameter of 5.6mm 2 , dried at 100°C, and calcined at 500°C in a muffle furnace to obtain the catalyst carrier. The Mo content in the carrier was determined to be 0.1 g / L by ICP.

[0101] Catalyst preparation:

[0102] (1) Use sodium bicarbonate pH regulator and water as a solvent to prepare a pH of 1.06, containing 3.18gPd and 0.37gCu of chloropalladic acid and copper chloride aqueous solution to obtain 590ml of impregnating solution. impregnating it on the catalyst carrier in a rotating pan to obtain catalyst precursor I;

[0103] (2) After drying at 80°C, 105ml contains 21.5g Na 2 SiO 3 9H 2 The solution of O was fully mixed, and aged for 24h to obtain catalyst precursor II;

[0104] (3) With a solubility of 10% (in N 2 h 4 ·H 2 (2 in weight ratio)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com