ZnO/mesoporous C3N4 composite photocatalyst and preparation method thereof

A catalyst and composite light technology, applied in the field of photocatalytic material research, can solve the problems of reducing energy level matching and affecting the catalytic activity of visible light, so as to improve the utilization rate, excellent performance of simulating sunlight photocatalytic degradation of pollutants, and cheap raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

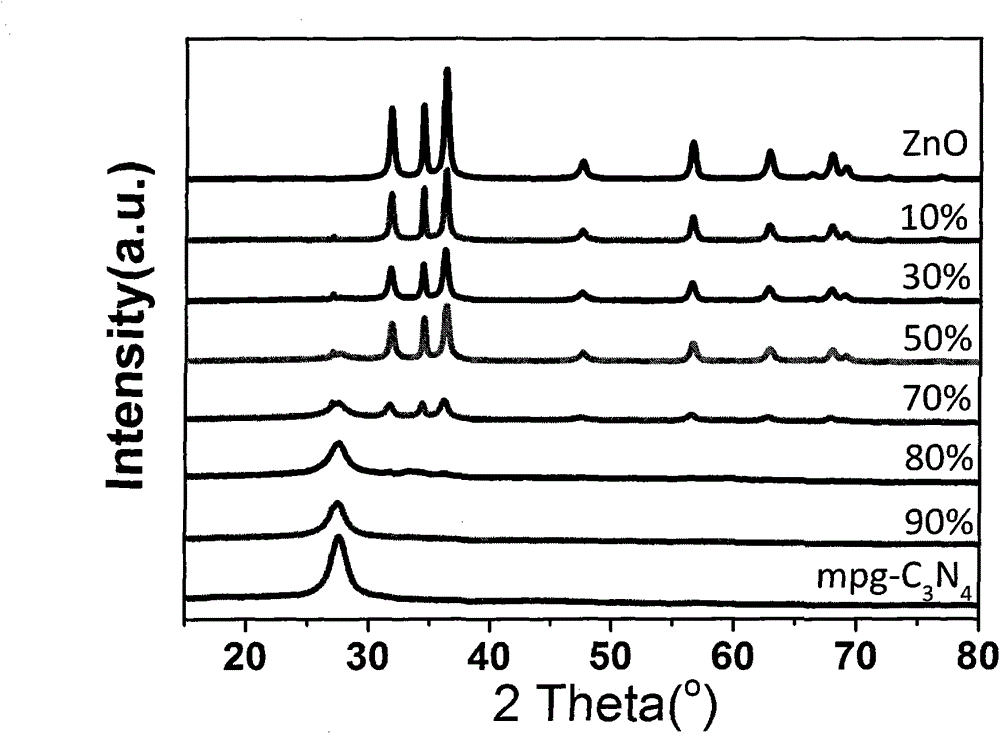

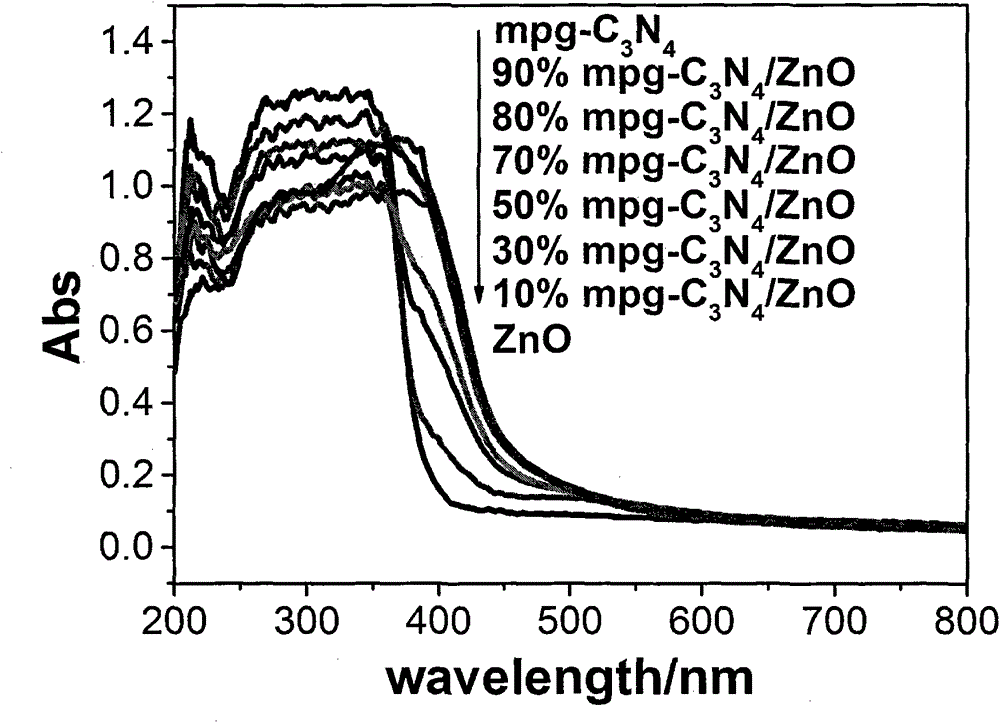

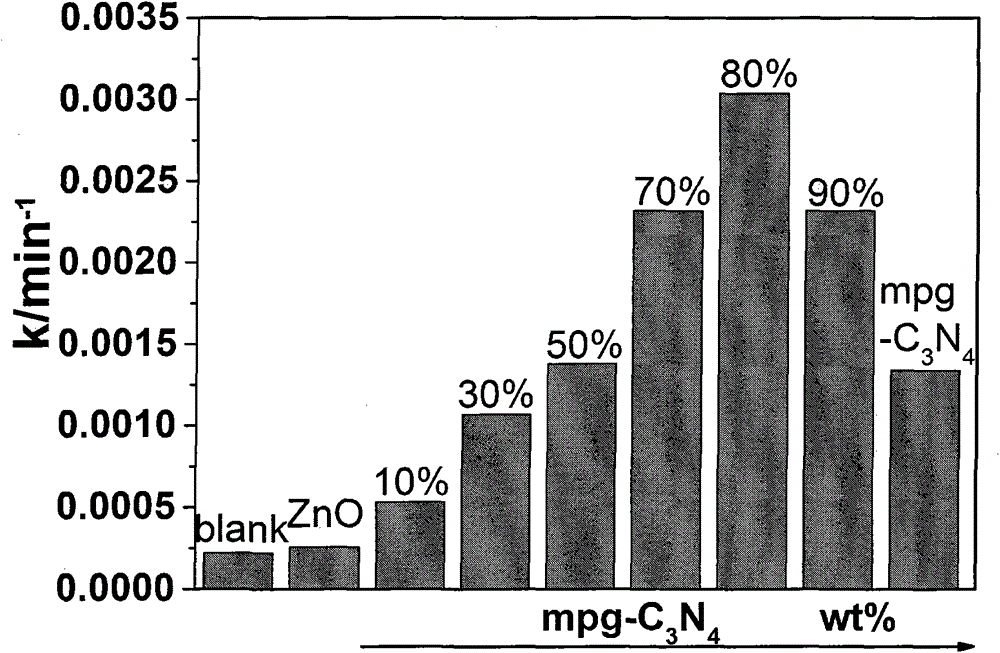

Embodiment 1

[0025] Weigh 0.025g of mpg-C 3 N 4 powder, added in 50ml ethylene glycol, ultrasonically dispersed for 0.5 hour, and then stirred for 1 hour; then weighed 0.6g of Zn(CH 3 COO) 2 .2H 2 O, ultrasonically dissolve into 60ml of ethylene glycol, add it to the above dispersion, and keep stirring for 0.5 hours; then weigh 0.219g of sodium hydroxide and dissolve it in 50ml of ethylene glycol, add it dropwise to the above mixed solution in, and continue to stir for 1 hour; then transfer the formed solution to a 200ml polytetrafluoroethylene-lined autoclave, and heat it at 160 degrees for 24 hours; after the product is centrifuged, washed and separated, it is dried in an oven for 24 hours. hours, the corresponding ZnO-loaded mesoporous mpg-C 3 N 4 Composite photocatalyst, labeled ZnO / mpg-C 3 N 4 (10wt.%).

Embodiment 2

[0027] Experimental procedure is identical with embodiment 1, and difference is that the mpg-C that takes by weighing 3 N 4 The powder is 0.095g. The corresponding ZnO-supported mesoporous mpg-C was obtained 3 N 4 Composite photocatalyst, labeled ZnO / mpg-C 3 N 4 (30wt.%).

Embodiment 3

[0029] Experimental procedure is identical with embodiment 1, and difference is that the mpg-C that takes by weighing 3 N 4 The powder was 0.222 g. The corresponding ZnO-supported mesoporous mpg-C was obtained 3 N 4 Composite photocatalyst, labeled ZnO / mpg-C 3 N 4 (50wt.%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com