Super-drainage pump for spontaneously transporting tiny water drops through antigravity and preparation method and application of super-drainage pump

An anti-gravity and hydrophobic pump technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of restricting the development of devices and complicated preparation work, and achieve low cost, obvious effect, and easy raw materials. The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

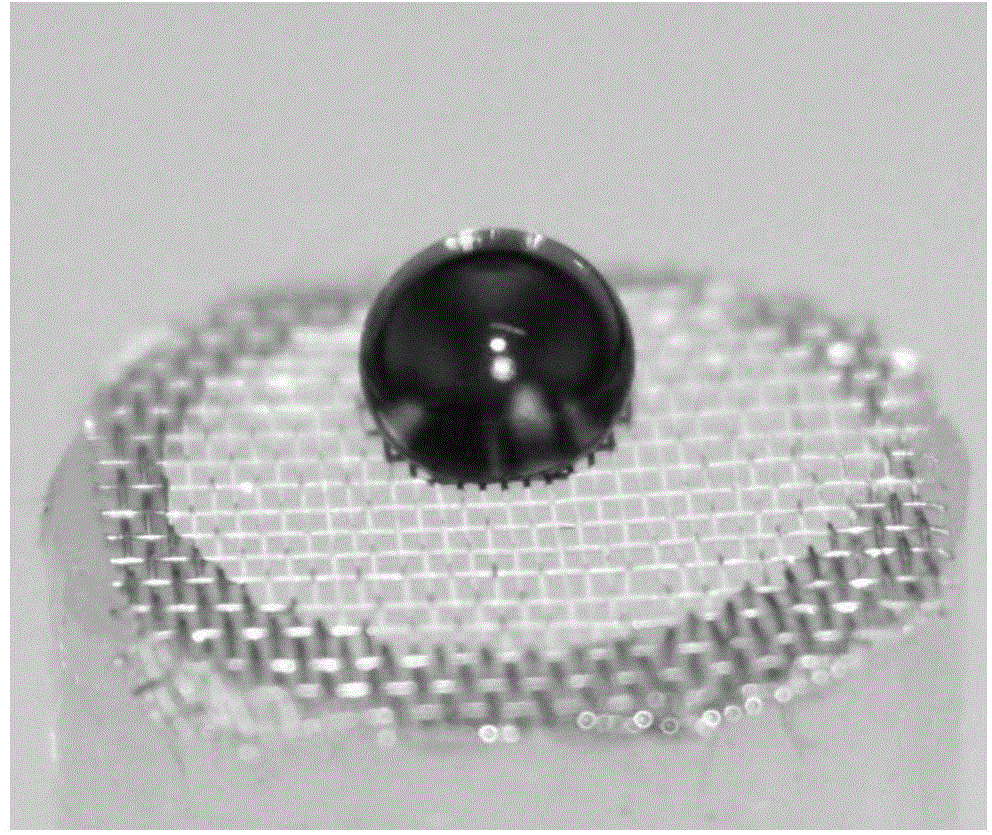

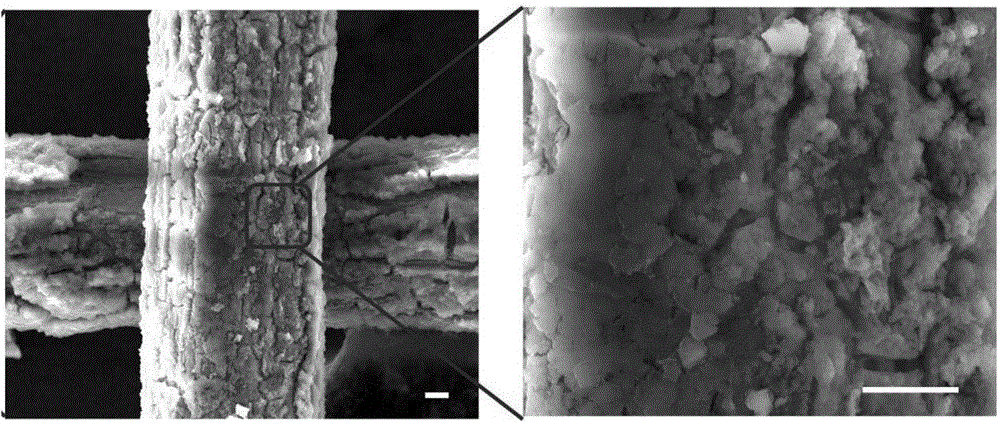

[0030] Soak a commercial 50-mesh copper mesh (with a maximum pore size of about 500 microns) in 4M hydrochloric acid for 10 minutes, then soak the copper mesh in 1M sodium hydroxide and 0.13M ammonium persulfate for 5 minutes, wash and dry. Utilize the ethanol solution of 1mM dodecyl mercaptan to soak after 2 hours, utilize ethanol to rinse clean, dry to obtain superhydrophobic macroporous mesh material 2, namely superhydrophobic copper mesh, such as Figure 1a As shown, the superhydrophobic copper mesh shown has superhydrophobicity, and the contact angle to water droplets is above 150°. Such as Figure 1b As shown, there is a typical micro-nano composite structure on the surface of the superhydrophobic copper mesh, and this type of structure plays an extremely important role in enhancing the hydrophobic performance of the copper mesh. The superhydrophobic copper mesh was bonded to the polymer tubing 1 with an inner diameter of 8 mm and an outer diameter of 10 mm by using cell...

Embodiment 2

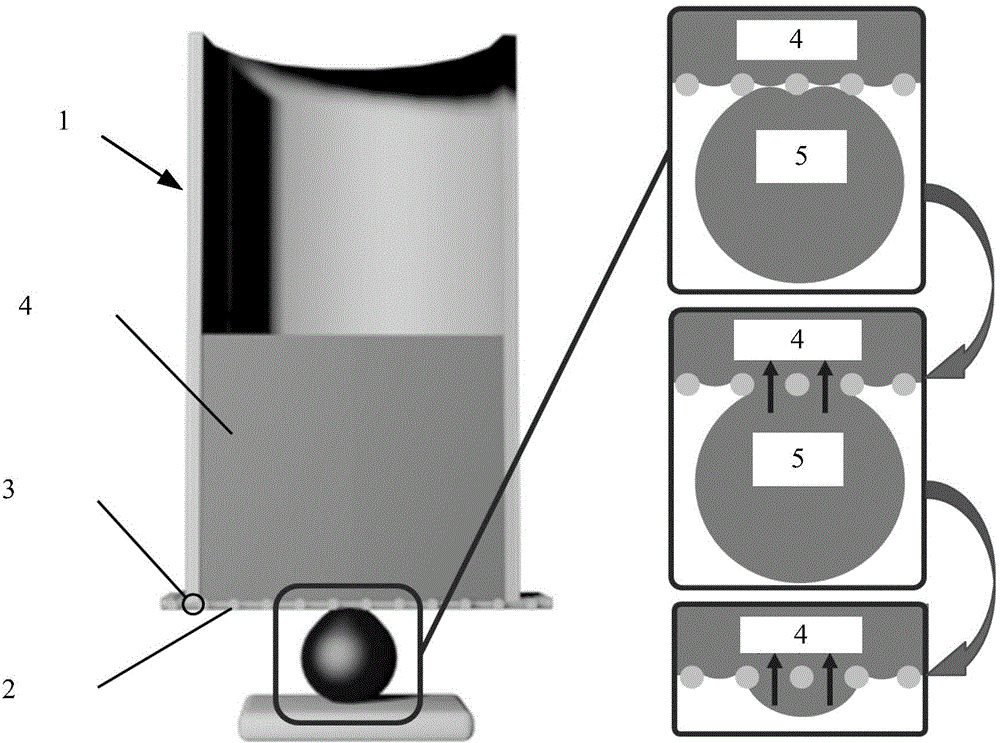

[0032] Soak a commercial 50-mesh copper mesh (with a maximum pore size of about 500 microns) in 4M hydrochloric acid for 10 minutes, soak the copper mesh in 1M sodium hydroxide and 0.13M ammonium persulfate for 5 minutes, wash and dry in the air. After soaking in 1 mM ethanol solution of dodecyl mercaptan for 2 hours, rinse with ethanol, and dry to obtain a superhydrophobic macroporous mesh material, that is, a superhydrophobic copper mesh. The superhydrophobic copper mesh was bonded to a polymer elbow with an inner diameter of 5 mm and an outer diameter of 6 mm by using cellulose-based polyacrylate adhesive tape to obtain a superhydrophobic pump. Such as Figure 4 As shown, the obtained super-hydrophobic pump is placed, and a 3-5 mm cellulose film layer is set in the elbow as the hydrophilic material layer 4 . Use a hydrophobic syringe to continuously transport the droplets to the lower surface of the superhydrophobic pump. Due to the asymmetric Laplace pressure, the droplet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com