Process for cleaning substrate of high-power condensation solar energy photoelectric receiver

A photoelectric receiver and high-power concentrating technology, which is applied in the field of solar photovoltaic power generation, can solve the problems of bonding wire shedding, bonding failure, false bonding, etc., and achieve the effects of cost control, defect rate reduction, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

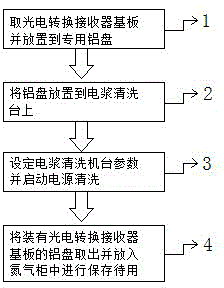

[0013] The present invention will be further described below with reference to the accompanying drawings. The compositional process steps in the accompanying drawings are not necessarily to scale, but describe the flow of the present invention in an emphatic manner.

[0014] see figure 1 , is a flow chart of the steps of the manufacturing process of the present invention. First, in step 1, the manufacturing process personnel load the high-power concentrating solar photoelectric conversion receiver substrate into a special aluminum plate, and fix the special aluminum plate on the aluminum plate frame. There is a certain distance between the layers; in step 2, transfer the aluminum tray rack to the plasma cleaning machine by hand-held or cart and other traction methods, and place the aluminum tray on the plasma cleaning machine; in step 3, The manufacturing process personnel set their cleaning process parameters, which include the number of cell substrates to be carried out, pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com