A quartz stone polishing and coating production line

A coating production line and quartz stone technology, which is applied to surface polishing machine tools, grinding/polishing equipment, stone processing tools, etc., can solve the problems of not being able to achieve luster and anti-fouling effects, and different production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

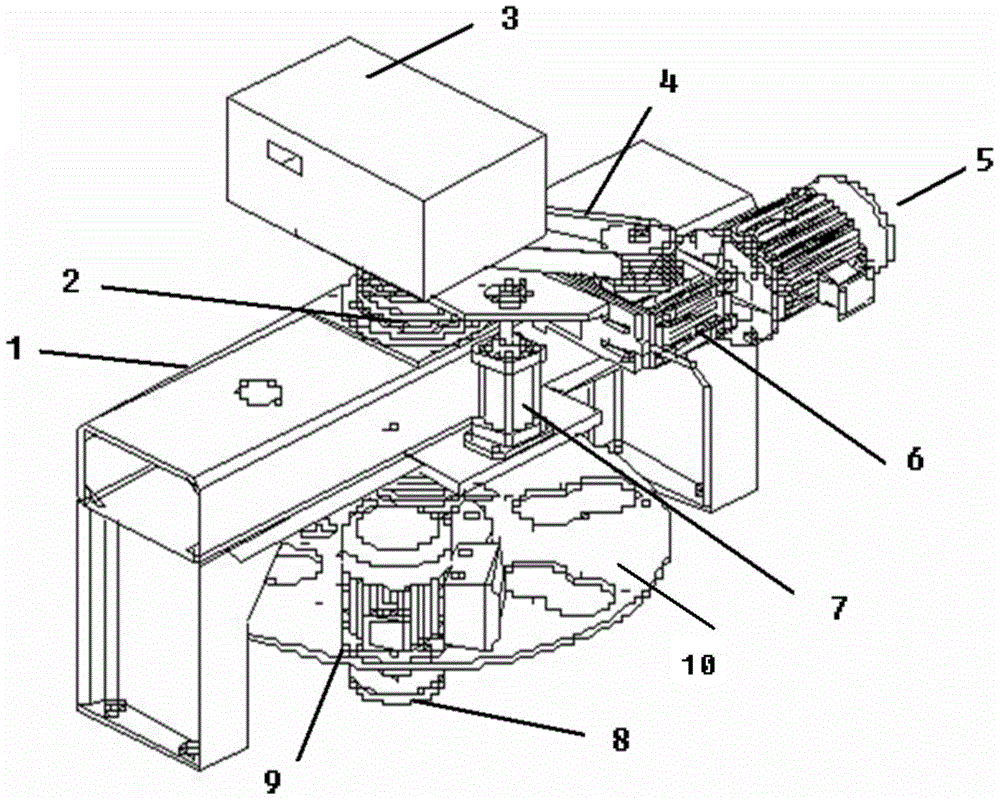

example 1

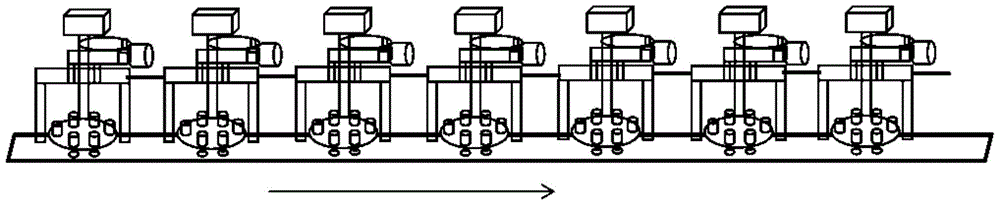

[0029] Example 1: See attached figure 2 . Use fixed rack mode. The fixed rack mode assembly line installs a plurality of large polishing discs on a complete frame, but there is no beam connecting the large polishing discs and they are separately fixed on the frame, and the frame has the same width as the large polishing discs. The quartz stone plate is driven into the frame by a belt, and is continuously polished by multiple large polishing discs in fixed positions, and then comes out from the other side after completion.

[0030] The quartz stone plate is a small plate of 760mm×2440mm, which adopts a fixed rack mode. A polishing disc mechanism for polishing quartz stone plates, with a large polishing disc with revolution (revolution speed: 40 rpm) and 6 small polishing discs with rotation (rotation speed: 960 rpm), with 7 configurations A large grinding disc, the diameter of the large grinding disc is 820mm, and the diameter of the small grinding disc is 170mm; the small ...

example 2

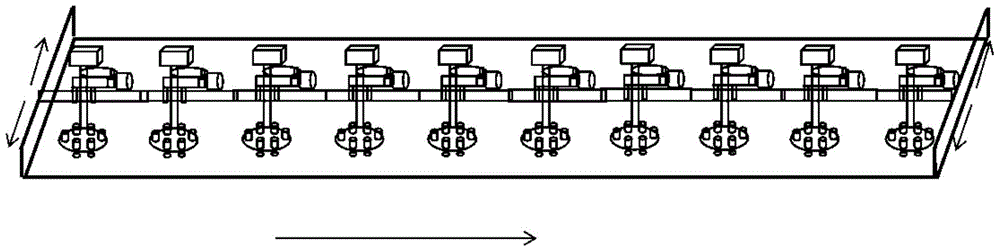

[0032] Example 2: See attached image 3 . Because some large quartz stone slabs have a width of 1.6m, a large polishing disc needs to be swung back and forth to cover all positions of the quartz stone slab. The frame width of the swing type assembly line is greater than 1.6m. Multiple large polishing discs are connected by beams and supported by both ends of the frame, and move back and forth on the frame. The quartz stone plate is driven into the frame by a belt, and is continuously polished by multiple large polishing discs, and then comes out from the other side after completion.

[0033] The quartz stone slab is a large slab of 1600mm×3200mm, which adopts the swing frame mode. A polishing disc mechanism for polishing quartz stone plates, with a large polishing disc with revolution (50 rpm) and 6 small polishing discs with rotation (1400 rpm), equipped with 10 A large grinding disc, the diameter of the large grinding disc is 850mm, and the diameter of the small grinding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com