Production equipment and production method of hollow corrugated polycarbonate sunlight plate

A technology of polycarbonate and production equipment, which is applied in the field of automatic continuous production, can solve the problems of poor weather resistance and peeling off of the coating layer, and achieve the effects of good load resistance, long service life and good UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

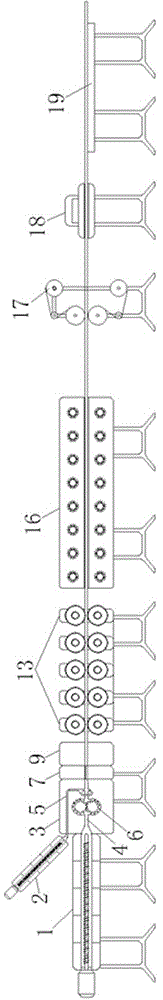

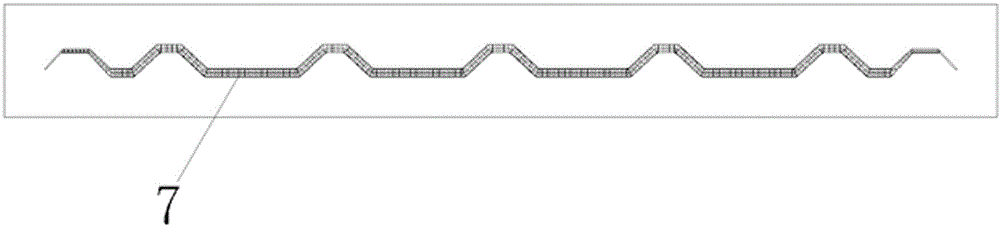

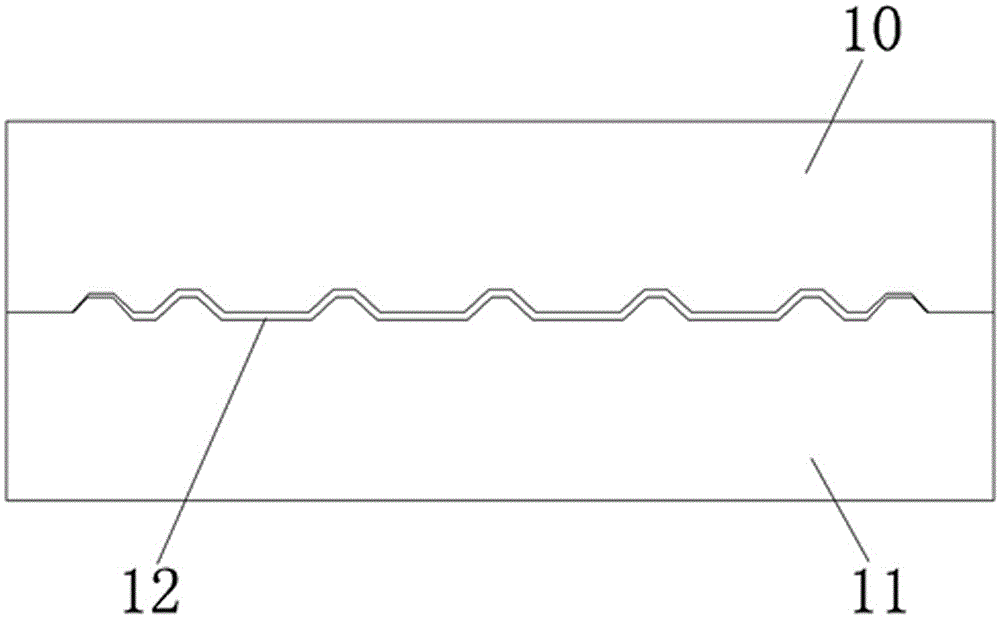

[0018] Such as Figure 1-Figure 4 Shown, a kind of production equipment of corrugated polycarbonate hollow sunlight board, including the main extruder 1 for extruding polycarbonate, the secondary extruder 2 for extruding anti-ultraviolet polycarbonate and from front to Distributor 3, die head 7, shaping table 9, pressure roller machine 13, oven 16, laminating machine 17, cutting machine 18 and transportation equipment 19 are arranged in sequence; distributor 3 is provided with main flow channel 4 and secondary flow channel 5. The secondary channel 5 is provided with two material outlets connected to the main channel 4 on the upper and lower sides of the main channel 4. The material outlet of the main extruder 1 is connected with the entrance of the main channel 4. The secondary extruder 2 The material outlet is communicated with the inlet of the auxiliary runner 5; the discharge port 8 of the die head 7 is corrugated as a whole; the shaping table 9 includes a lower shaping die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com