New ammonia water storage device

A storage device and ammonia water technology, applied in the field of chemical machinery, can solve problems affecting process use, reduce ammonia concentration, loss, etc., and achieve the effects of ingenious and simple structural design, reduced labor intensity, and safe and effective storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

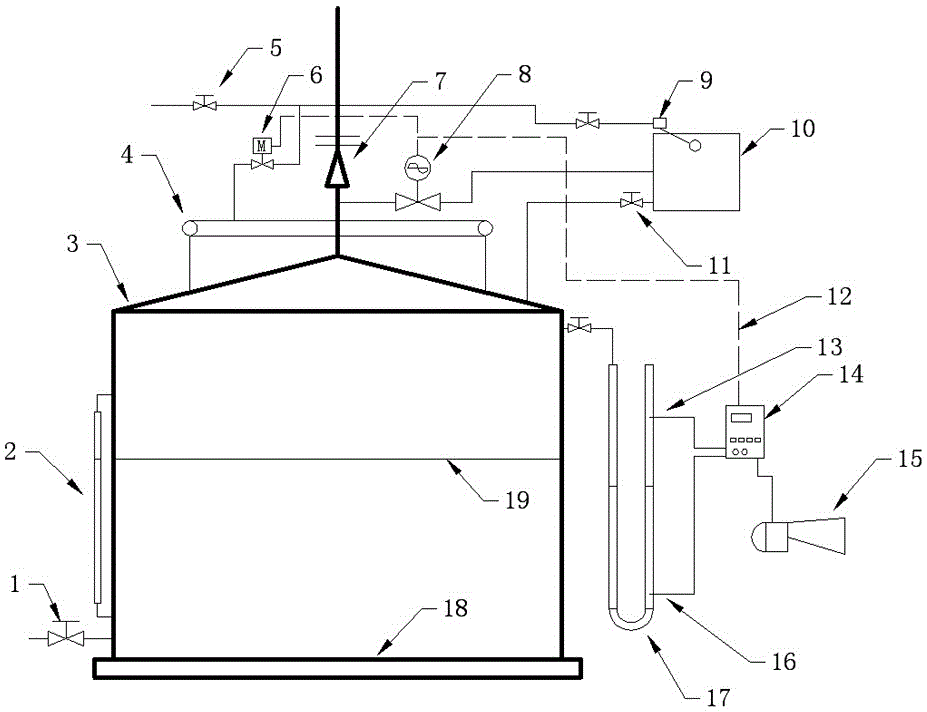

[0023] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0024] Such as figure 1 The new ammonia water storage device shown includes a tank body 3, and the part above the ammonia water liquid level 19 of the tank body 3 is connected to a transparent U-shaped communication device 17, and the transparent U-shaped communication device 17 is connected and controlled by an upper liquid level electrode 13 and a lower liquid level electrode 16. Device 14; an annular spray pipe 4 is arranged above the tank body 3, and the annular spray pipe 4 communicates with the tank body 3, and the annular spray pipe 4 communicates with the water inlet valve 5 through the solenoid valve 6; the water inlet valve 5 passes through the float valve 9 Connected to the water tank 10, the water tank 10 is provided with an electric valve 8 and an ordinary valve 11, two channels communicate with the tank body 3; the controller 14 has a control cable 12 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com