Special system for reduction treatment of building waste mud

A special system and waste mud technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, special treatment targets, etc., can solve the problems of easy pollution of the environment, pollution of the environment, and high cost of treatment methods. Achieve the effect of improving transportation efficiency and reducing foreign transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

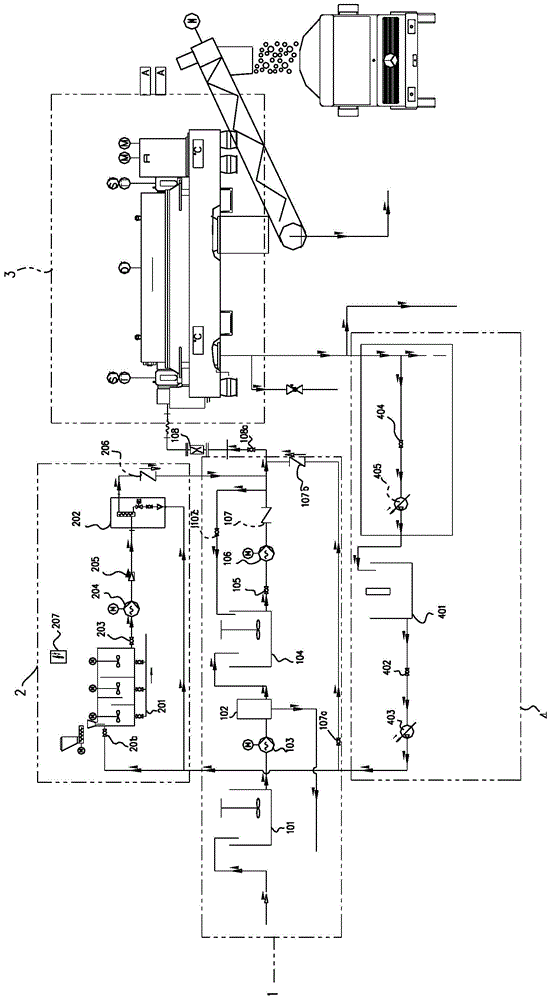

[0019] as attached figure 1 As shown, a special system for construction waste mud reduction treatment is characterized in that it includes a pretreatment system 1, a dosing system 2, a dehydration separation system 3 and a water reuse system 4, and the output terminal of the pretreatment system 1 Connected to the dehydration separation system 3, the clear liquid output end of the dehydration separation system 3 is connected to the reclaimed water system 4, and the output end of the reclaimed water system 4 is connected to the dosing system 2 and the pretreatment system 1.

[0020] Described pretreatment system 1 comprises mud pool 101, and the output end of described mud pool 101 is connected with slag removing device 102, and the first slurry pump 103 is installed on the connecting pipeline of described mud pool 101 and slag removing device 102, removes The output end of the slag device 103 is connected to the homogeneous pool 104, and the output end of the homogeneous pool 1...

Embodiment 2

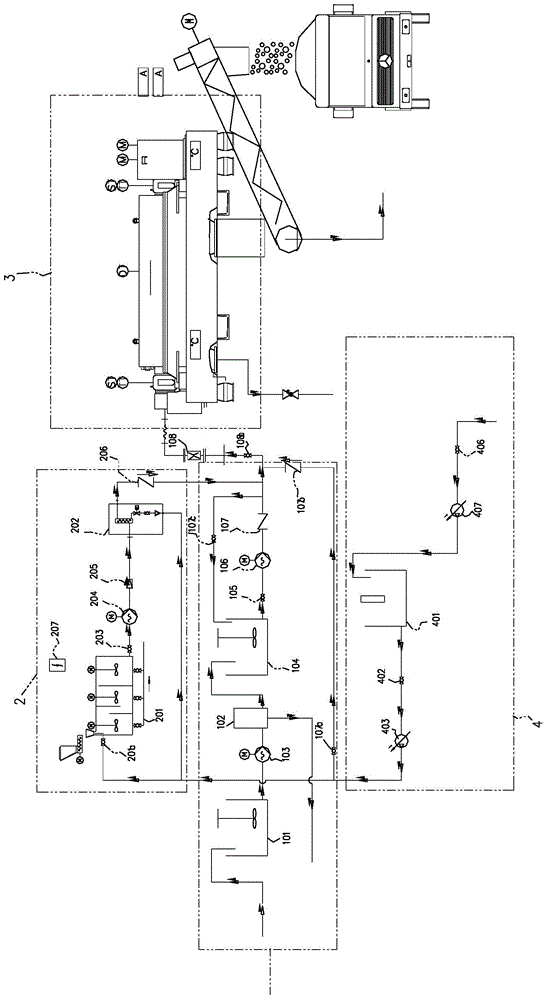

[0027] as attached figure 2 As shown, when there is running water on site, the input end of the water tank 401 can be externally connected to the running water pipeline, and a manual water valve 406 and a running water pipeline pump 407 are installed on the connecting pipeline between the input end of the water tank 401 and the running water pipeline.

[0028] In the present invention, large particles are firstly removed by a slag removal device, and then an appropriate amount of PAC agent is added, and the concentration is adjusted by adding water, and the concentration is uniformly passed through a mixer continuously during the whole pretreatment process. At the same time of pretreatment, the dosing system will prepare the appropriate PAM flocculant according to a certain concentration, and the prepared solution will be mixed with the pretreated waste mud in the pipeline, and pumped to the dehydration separation system, which will be separated by centrifugation. Dehydration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com