Forming method of variable-density broadband wave-transparent quartz composite ceramic radome

A composite ceramic and molding method technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of no multi-frequency and broadband, achieve good structural strength and reduce antenna phase. Distortion, improve the effect of dipping compound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for forming a variable-density broadband wave-transmitting quartz composite ceramic radome cover body, comprising the following steps:

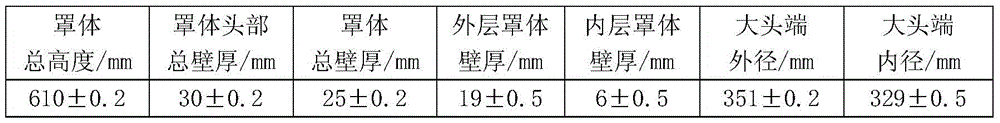

[0028] 1) Design the radome cover according to the size and quality requirements of the cover, and its dimensions are shown in the following table:

[0029] Table 1 Main product dimensions

[0030]

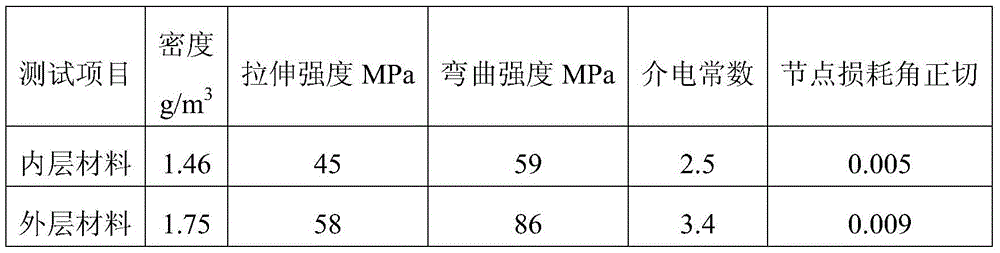

[0031] 2) adopt the quartz glass fiber yarn as the outer layer material of the cover, and the hollow quartz glass fiber yarn as the inner layer material, and the outer layer material and the inner layer material are integrally woven to obtain the inner and outer cover fabrics; wherein,

[0032] The volume percentage of the quartz fiber yarn in the outer layer material is 40-45%, the density of the quartz fiber yarn is 190-198 tex, the SiO 2 Content ≥ 99.92%, single filament breaking strength ≥ 70KN; the volume percentage of hollow quartz fiber yarn in the inner layer material is 25-30%, the density of hollow quartz fiber yarn ...

Embodiment 2

[0040] A method for forming a variable-density broadband wave-transmitting quartz composite ceramic radome cover body, comprising the following steps:

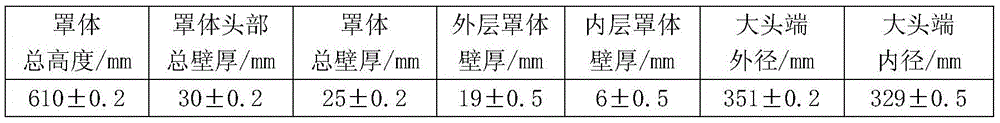

[0041] 1) Design the radome cover according to the size and quality requirements of the cover, and its dimensions are shown in the following table:

[0042] Table 1 Main product dimensions

[0043]

[0044]2) adopt the quartz glass fiber yarn as the outer layer material of the cover, and the hollow quartz glass fiber yarn as the inner layer material, and the outer layer material and the inner layer material are integrally woven to obtain the inner and outer cover fabrics; wherein,

[0045] The volume percentage of the quartz fiber yarn in the outer layer material is 40-45%, the density of the quartz fiber yarn is 190-198 tex, the SiO 2 Content ≥ 99.92%, breaking strength of monofilament ≥ 70KN;

[0046] The volume percentage of the hollow quartz fiber yarn in the inner layer material is 25-30%, the density of the hollow q...

Embodiment 3

[0053] A method for forming a variable-density broadband wave-transmitting quartz composite ceramic radome cover body, comprising the following steps:

[0054] 1) Design the radome cover according to the size and quality requirements of the cover, and its dimensions are shown in the following table:

[0055] Table 1 Main product dimensions

[0056]

[0057] 2) adopt the quartz glass fiber yarn as the outer layer material of the cover, and the hollow quartz glass fiber yarn as the inner layer material, and the outer layer material and the inner layer material are integrally woven to obtain the inner and outer cover fabrics; wherein,

[0058] The volume percentage of the quartz fiber yarn in the outer layer material is 40-45%, the density of the quartz fiber yarn is 190-198 tex, the SiO 2 Content ≥ 99.92%, single filament breaking strength ≥ 70KN; the volume percentage of hollow quartz fiber yarn in the inner layer material is 25-30%, the density of hollow quartz fiber yarn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com