Thermoplastic resin composition and preparation method thereof

A technology of thermoplastic resin and composition, which is applied in the field of thermoplastic resin composition and its preparation, and can solve the problem of low concentration in essence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

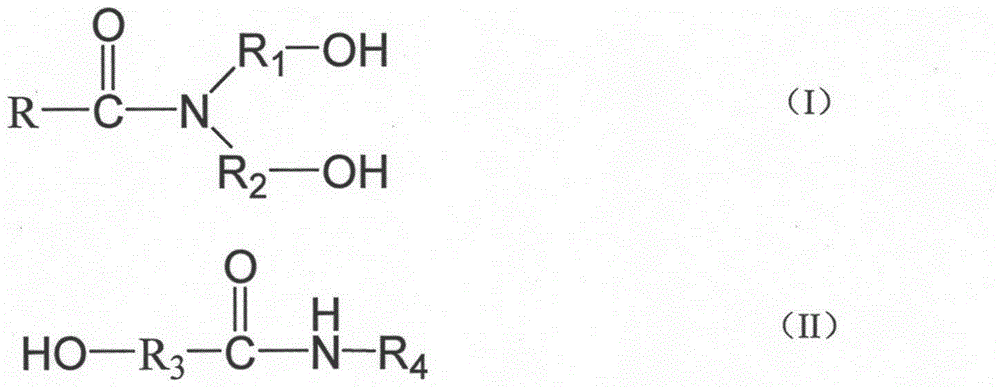

Method used

Image

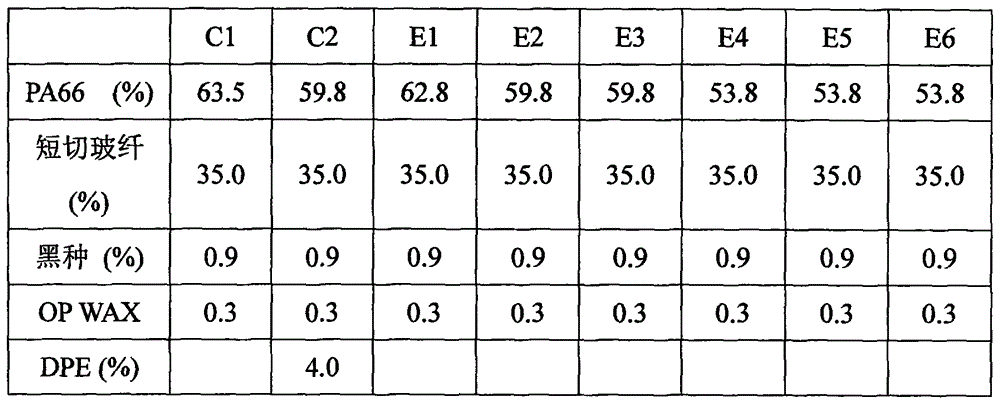

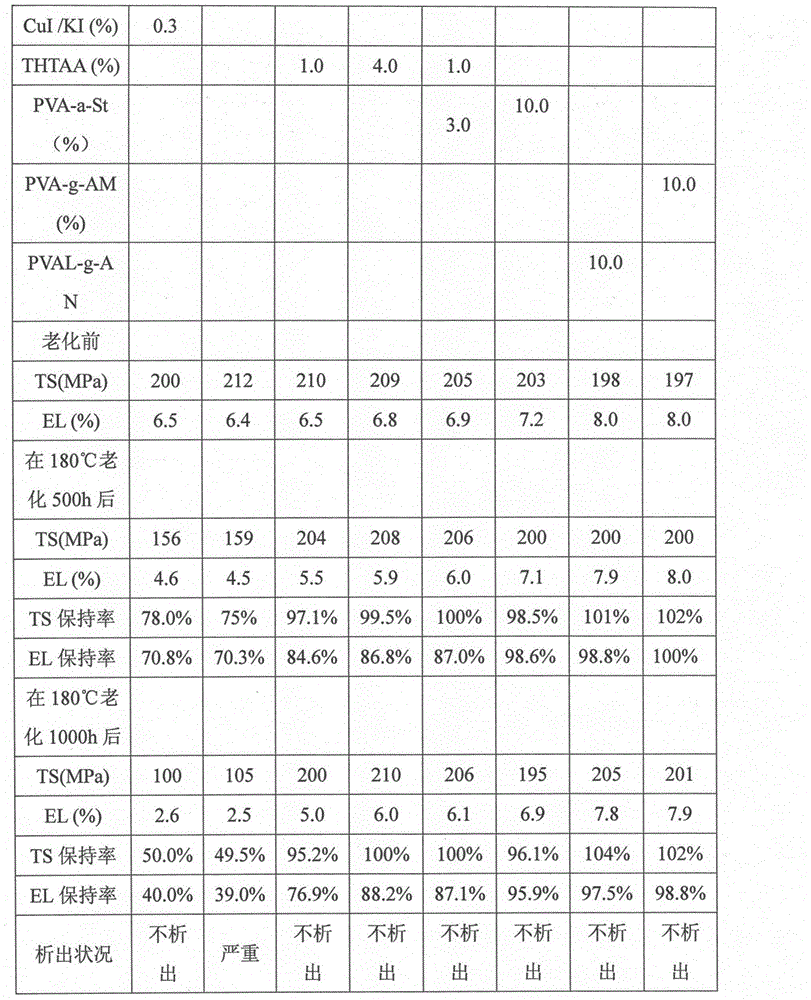

Examples

Embodiment 1-14

[0075] Synthesis of THTAA: Add ethylene oxide and ammonia water with a concentration of 25% into the reactor, the molar ratio of ethylene oxide and ammonia is 3:2, stir and react at room temperature for 1 hour, and rectify according to different boiling points to obtain diethanolamine ; Methyl eicosanoate and diethanolamine are added in a molar ratio of 1:2 into the reaction kettle, and sodium ethylate is added. The amount of sodium ethylate is the total weight of methyl eicosanoate and diethanolamine 0.15wt%, the reaction temperature is 80 ℃, and vacuumize the pressure in the reactor to be lower than 60mmHg, after reacting for 2.5h, neutralize to pH 7 with 0.1mol / L hydrochloric acid, remove unreacted by vacuum distillation Diethanolamine, to give THTAA.

[0076] Synthetic PVA-a-St: stearamide (accounting for total weight 7.5wt%) is dropped into reactor, adds DMSO (accounting for total weight 80wt%), is heating and dissolving under the condition of 60 ℃ at temperature, adds (a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com