Preparation method of portable and movable straw sheet and plate prepared by preparation method

A technology of straw boards and straws, which is applied in the field of convenient and mobile straw board preparation methods and the boards produced, can solve the problems of complex industrial scale production process, limited range of raw material collection, and high cost of straw transportation, and reduce cost input , strong feasibility, and the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Raw asphalt and / or polymer and / or rubber and plastic materials and equipment, including switchboards or diesel generators, vibrating platforms, formwork molds treated with non-stick Teflon materials, harmless incinerators or electric heating Or a fuel-fired gas-type heat container, a small liquid sprayer, a small manipulator, a small hot and cold dual-purpose press, and a conveyor belt are transported to the field after harvesting by a small truck or an agricultural vehicle. In this embodiment, the harmless incinerator type is used. The heat container heats the raw materials, and the power source leads the rural agricultural electricity to the switchboard for the rest of the equipment.

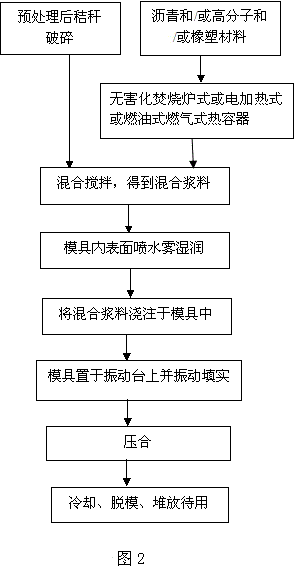

[0049] as attached figure 1 The described flow process carries out the following production and processing:

[0050] a. Place the template mold on the vibration table, start the vibration platform to adjust its vibration frequency to make it vibrate;

[0051] b. After pretreatment, the ...

Embodiment 2

[0060] Rubber and plastic raw materials and equipment, including switchboards or diesel generators, vibration platforms, formwork molds with cooling systems, flat plates with hydrophobic morals, harmless incinerators or electric heating or oil-fired gas-fired heat containers, small Manipulators, small sprayers, small hot and cold dual-purpose presses, conveyor belts, small mixers and crushers are transported to the fields after harvest by agricultural vehicles and / or small special equipment flatbeds. In this embodiment, an electric heating type heat container is adopted, and a diesel generator is used as the power source of the rest of the equipment.

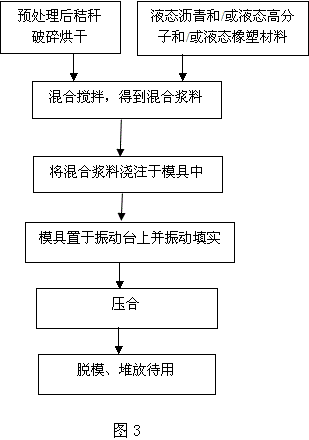

[0061] as attached figure 2 The described flow process carries out the following production and processing:

[0062] a. Place the disc-type flat plate and template mold on the vibrating table in turn, adjust its vibration frequency and make it vibrate;

[0063] b. Use a small sprayer to spray and wet the inner surface of the ...

Embodiment 3

[0072] Liquid asphalt and / or liquid polymer and / or liquid rubber and plastic materials and equipment, including switchboards or diesel generators, vibrating platforms, cold or hot press molds with surfaces treated with non-stick Teflon materials , liquid asphalt and / or liquid polymer and / or liquid rubber and plastic material mixer, straw crusher, dryer, small sprayer, small cold press or small hot press, agricultural vehicles for conveyor belts and / or small special-purpose The equipment is flatbed and transported to the field after harvesting. Diesel generators are used as the source of power for the rest of the equipment where agricultural electricity is inconvenient. In this embodiment, rural agricultural electricity is used as the source of power for the equipment.

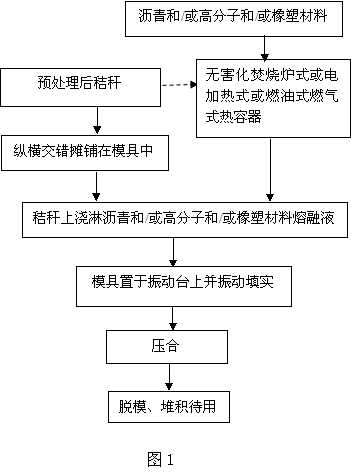

[0073] as attached image 3 The described flow process carries out the following production and processing:

[0074] a. Install the cold press mold or hot press mold on the vibration platform and make it vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com