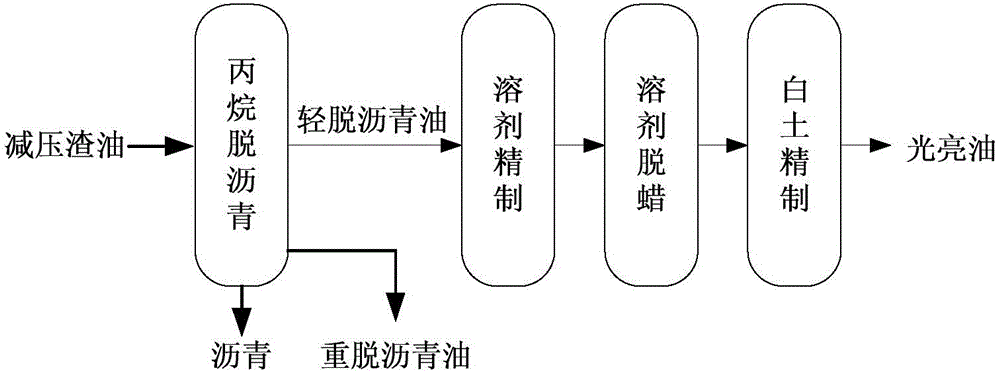

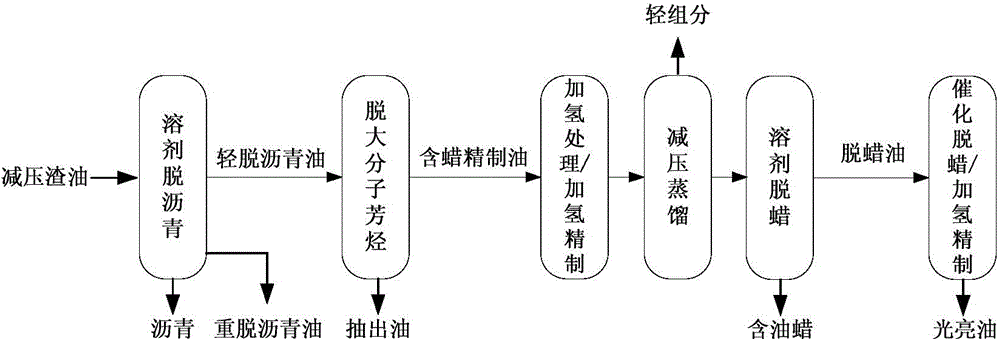

Production method of bright stock with low pour point and high viscosity

A production method and high-viscosity technology, used in hydrocarbon oil treatment products, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of high pour point, poor photothermal stability, high content of sulfur nitrogen and aromatic hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of hydrogenation supplementary refining catalyst: the amorphous silicon-alumina carrier is prepared by using the method of co-current fixed pH value and silicon-aluminum co-precipitation. After the carrier is dried and roasted, it is extruded into a clover-shaped strip. After drying and roasting, the precious metal Pt is loaded by impregnation method, and then dried and roasted to prepare a hydrogenation supplementary refining catalyst. The content of Pt is 0.5% by weight, and the rest is no Shaped silica-alumina carrier with a specific surface area of 303m 2 / g, the average pore volume is 1.06ml / g.

[0038] The isomerization dewaxing catalyst and supplementary refining catalyst need to be pre-reduced before use. The reduction conditions are: the catalyst is crushed into particles with a length of 2mm-4mm, loaded on a 200ml high-pressure hydrogenation reaction test device, and the hydrogen flow rate is 2000ml / h. 2 hours at 5°C / min, then raised ...

Embodiment 1

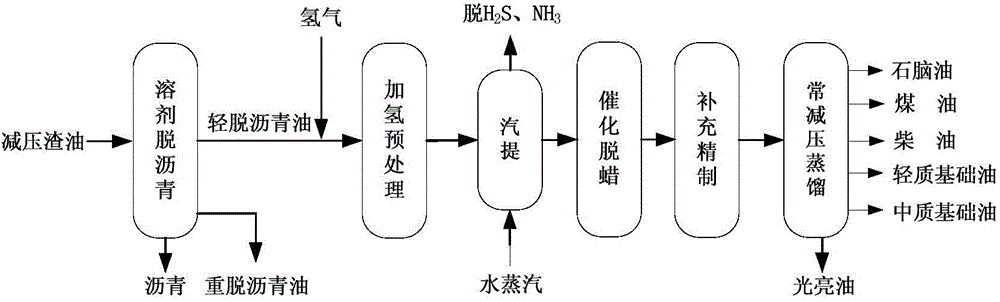

[0041] Example 1 Hydrogenation Pre-refining-Isomerization Dewaxing-Hydrogenation Supplementary Refining Process

[0042] according to Figure 4 The shown hydrogenation pre-refining-isomerization dewaxing-hydrogenation supplementary refining process produces bright stock. The test equipment and the properties of the raw oil are the same as those of Comparative Example 1. The process conditions are shown in Table 2.

[0043] The product distribution of embodiment 1 and comparative example 1 is shown in table 3, and the main product properties are shown in table 4.

[0044] It can be seen from Tables 1 to 4 that the bright stock obtained in Comparative Example 1 and Example 1 can meet the quality requirements of high-pressure hydrogenated white 150BS bright stock. However, compared with Comparative Example 1, the operating conditions of Example 1 are more moderate, the yield of bright stock is 17.8 percentage points higher, the total yield of base oil is 16.3 percentage points h...

Embodiment 2

[0057] According to the technical process selected in Example 1, select the same catalyst, experimental device and feedstock oil as in Example 1, the hydrogenation pre-refining and hydrogenation supplementary refining process conditions are the same as in Example 1, and the hydroisomerization dewaxing process conditions See Table 5 for details, and Table 6 for main product properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com