Amorphous alloy spectacle frame and glass and production method thereof

An amorphous alloy, zirconium-based amorphous alloy technology, applied in glasses/goggles, non-optical components, instruments, etc., can solve the problem of large nickel release, wearer's skin allergy, strength, elastic limit and Vickers hardness and other problems such as unsatisfactory performance, to achieve the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] An amorphous alloy spectacle frame of this embodiment is made of a zirconium-based amorphous alloy, and the zirconium-based amorphous alloy is composed of atoms in the following atomic percentages:

[0061] Zr 52.5%

[0062] Ti 5%

[0063] Cu 17.9%

[0064] Ni 14.6%

[0065] Al 10%.

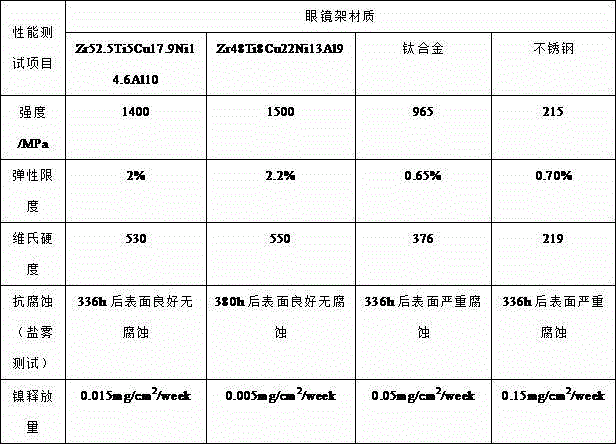

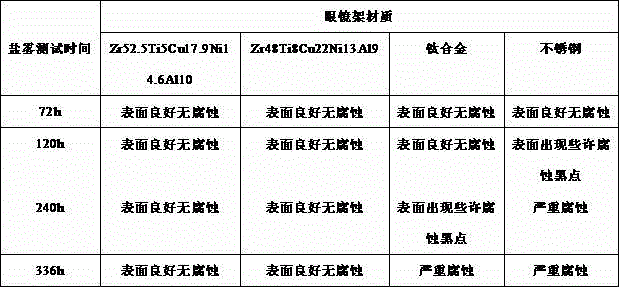

[0066] The specific preparation method of the amorphous alloy spectacle frame is to prepare spectacle frames by vacuum suction casting using zirconium-based amorphous alloy Zr52.5Ti5Cu17.9Ni14.6Al10 under the protection of vacuum and nitrogen. It is 1400MPa, the elastic limit is 2%, and the Vickers hardness is 530. After 336 hours of salt spray test, the surface of the spectacle frame is still good without corrosion. In this example, the nickel release amount of the spectacle frame prepared by using the zirconium-based amorphous alloy Zr52.5Ti5Cu17.9Ni14.6Al10 is 0.015 mg / cm 2 / week, the nickel release is equivalent to 1 / 10 of the nickel release of spectacle frames made of stainless s...

Embodiment 2

[0069] An amorphous alloy spectacle frame of this embodiment is made of a zirconium-based amorphous alloy, and the zirconium-based amorphous alloy is composed of atoms in the following atomic percentages:

[0070] Zr 48%

[0071] Ti 8%

[0072] Cu 22%

[0073] Ni 13%

[0074] Al 9%.

[0075] The specific preparation method of the amorphous alloy spectacle frame is to prepare the spectacle frame by using the zirconium-based amorphous alloy Zr48Ti8Cu22Ni13Al9 under the protection of a vacuum state and helium through the belt throwing method. The strength of the prepared spectacle frame is 1500MPa, and the elastic limit is 2.2%, the Vickers hardness is 550, and the surface of the spectacle frame is still good without corrosion after 380 hours of salt spray test. In this example, the nickel release amount of the spectacle frame prepared by using the zirconium-based amorphous alloy Zr48Ti8Cu22Ni13Al9 is 0.005 mg / cm 2 / week, the nickel release amount is equivalent to 1 / 10 of th...

Embodiment 3

[0078] An amorphous alloy spectacle frame of this embodiment is made of a zirconium-based amorphous alloy, and the zirconium-based amorphous alloy is composed of atoms in the following atomic percentages:

[0079] Zr 60%

[0080] Ti 3%

[0081] Cu 20%

[0082] Ni 12%

[0083] Al 5%.

[0084] The specific preparation method of the amorphous alloy spectacle frame is to prepare the spectacle frame by rapid discharge molding using the zirconium-based amorphous alloy Zr60Ti3Cu20Ni12Al5 under the protection of vacuum and neon gas. The strength of the spectacle frame is 1600MPa, and the elastic limit 2.5%, the Vickers hardness is 600, and the surface of the spectacle frame is still good without corrosion after 480 hours of salt spray test. In this example, the nickel release amount of the spectacle frame prepared by using the zirconium-based amorphous alloy Zr60Ti3Cu20Ni12Al5 is 0.010 mg / cm 2 / week, the amount of nickel release is extremely small compared to spectacle frames mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com