Manufacturing method of medical chitosan antibacterial fibers

The technology of chitosan fiber and antibacterial fiber is applied in the field of medical antibacterial sterilization and rope, which can solve the problems of poor antibacterial and sterilization effect of antibacterial fiber and complicated preparation process of antibacterial fiber, and achieve the effect of good effect and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

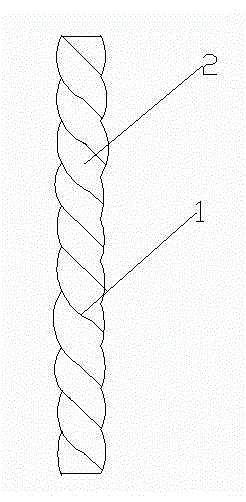

Image

Examples

preparation example Construction

[0015] The preparation method of medical chitosan antibacterial fiber thread comprises the steps:

[0016] (1) Material selection: choose chitosan antibacterial fiber filament, its specification is 105D-210D, diameter is 0.1-0.5mm; the chitosan antibacterial fiber filament treatment process is: chitosan fiber is beaten and chopped Dispersing, using sodium dodecylbenzene sulfonate to wash and pretreat chitosan fibers, adding a dispersant to obtain chitosan antibacterial fiber filaments;

[0017] (2) Doubling: 2-5 treated chitosan antibacterial fiber filaments are used for doubling and 1 strand;

[0018] (3) Twisting: After paralleling, the chitosan antibacterial fiber filaments are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be controlled by a tension regulator, and its speed and twist are measured regularly , the twist is less than 20 twists / m;

[0019] (4) Heat setting: Heat the twisted chitosa...

Embodiment 1

[0022] The preparation method of medical chitosan antibacterial fiber thread comprises the steps:

[0023] (1) Material selection: choose chitosan antibacterial fiber filament, its specification is 105D, and the diameter is 0.1-0.5mm; Chitosan fiber is washed and pretreated by sodium dialkylbenzenesulfonate, and a dispersant is added to obtain chitosan antibacterial fiber filament;

[0024] (2) Paralleling: 2 chitosan antibacterial fiber filaments are used for paralleling to form 1 strand;

[0025] (3) Twisting: After paralleling, the chitosan antibacterial fiber filaments are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be controlled by a tension regulator, and its speed and twist are measured regularly , the twist is less than 20 twists / m;

[0026] (4) Heat setting: heat setting the twisted chitosan antibacterial fiber filament through a steam setting machine at a temperature of 60°C and a pres...

Embodiment 2

[0029] The preparation method of medical chitosan antibacterial fiber thread comprises the steps:

[0030] (1) Material selection: Chitosan antibacterial fiber filaments are selected, the specification is 160D, and the diameter is 0.1-0..5mm; the treatment process of chitosan antibacterial fiber filaments is: beating and chopping the chitosan fibers, Using sodium dodecylbenzene sulfonate to carry out washing pretreatment to chitosan fiber, add dispersant, obtain chitosan antibacterial fiber filament;

[0031] (2) Paralleling: 4 chitosan antibacterial fiber filaments are used in paralleling to form 1 strand;

[0032] (3) Twisting: After paralleling, the chitosan antibacterial fiber filaments are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be controlled by a tension regulator, and its speed and twist are measured regularly , the twist is less than 20 twists / m;

[0033] (4) Heat setting: heat setti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com