A steel bridge deck pavement structure and pavement method

A bridge deck pavement and steel bridge deck technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems that ordinary reinforced concrete cannot meet the requirements, the surface tensile strain of the bridge deck pavement is too large, and the bridge deck pavement Insufficient durability and other problems, achieve the effect of improving local cracking, facilitating mechanized construction, and maintaining the same pull-out resistance and shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

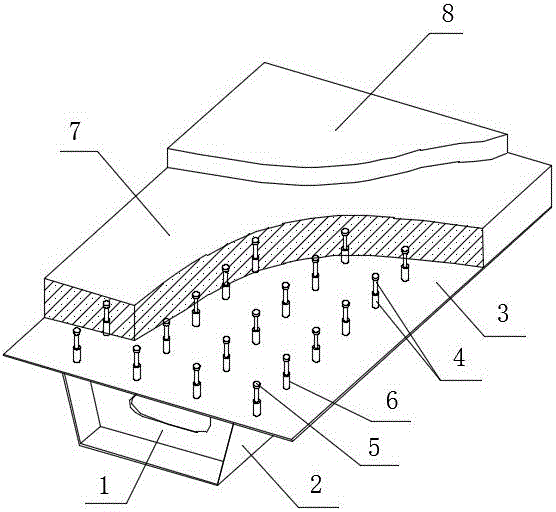

[0021] Such as figure 1 The steel bridge deck pavement structure and pavement method shown include the top plate 3 and the longitudinal web 2 fixedly connected to the bottom surface of the top plate 3 and the transverse diaphragm 1, and the longitudinal web 2 and the transverse diaphragm 1 are connected orthogonally.

[0022] A flexible connector 4 is provided on the top surface of the top plate 3, and the flexible connector 4 is rectangular or quincunx-shaped and uniformly welded on the top plate 3. The flexible connector 4 includes a rigid column 5 and a 1 / 3-3 The flexible cladding body 6 wrapped at the height of / 4, the rigid column 5 and the top plate 3 are vertically welded.

[0023] A bridge deck pavement layer is laid on the top surface of the roof 3, the bridge deck pavement layer includes a steel fiber concrete layer 7 and an asphalt concrete layer 8 laid sequentially from bottom to top, and the top surface of the flexible connector 4 is lower than the bridge deck Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com