River channel segmental desilting construction method

A river channel and silt technology, applied in the field of channel dredging construction, can solve the problems of inconvenient operation, low efficiency, and secondary pollution of surrounding sites, and achieve the effects of avoiding secondary pollution, improving treatment efficiency, and accelerating drainage consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

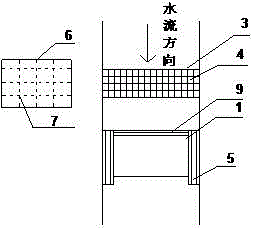

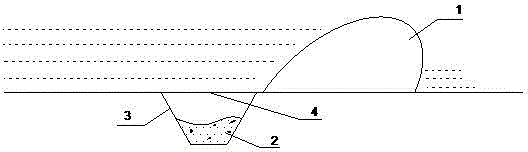

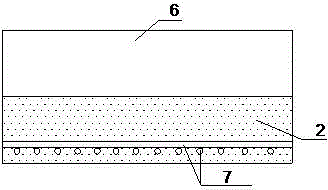

[0030] Such as Figure 1~4 As shown, in the river course to be dredged, a vertical fence 9 is arranged upstream of the flexible dam 1, and drainage gates 5 are arranged on both sides of the flexible dam 1, and a silting ditch 3 is arranged upstream of the flexible dam 1, and a silting ditch 3 is arranged on the upstream of the flexible dam 1, and the The silt ditch 3 is covered with a mesh cover 4, and the sludge 2 falls into the silt ditch 3 through the mesh cover 4. The flexible dam 1 is also equipped with a sludge treatment tank 6, in which a drainpipe 7 is arranged, and a geomembrane 8 is wrapped on the outside of the drainpipe 7, and the bottom of the sludge treatment tank 6 is provided with a collector for discharging silt 2 moisture. water hole 10.

[0031] The method for segmental desilting construction of a river course comprises the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com