Triolocation compensation algorithm for single-shaft fiber-optic gyroscope in oil well survey

A fiber optic gyro and three-position technology, which is applied in the directions of measurement, wellbore/well components, earthwork drilling and production, etc., can solve problems such as the inability to use tubing trajectory testing, limited working hours, and high heat generation, and achieves simplified structures and circuits Excellent design, low heat generation, and the effect of saving instrument cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

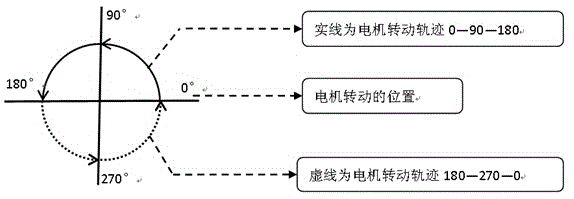

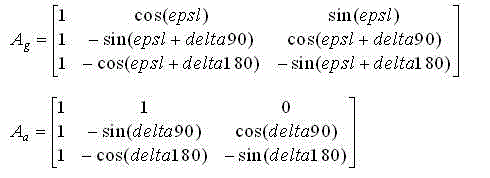

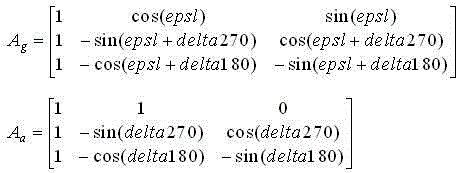

[0016] figure 1 It shows the schematic diagram of the motor transposition of the single-axis fiber optic gyro of the present invention when measuring the inclination of the oil well. The present invention adopts the installation structure of a gyroscope and an accelerometer, adopts the compensation calculation method for the output value, and uses an accelerometer to rotate through the motor. The position process is used to record its value; the gyro inclinometer is composed of a single-axis fiber optic gyroscope and a single-axis accelerometer. The mechanical connection between the fiber optic gyroscope and the accelerometer and the indexing mechanism uses a slip ring. Each measuring point uses three positions to calculate the azimuth and The well deviation does not need to be returned to zero, and the position is shifted in one direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com