Multifunctional structure with heat absorption cooling effect and vibration reduction effect

A shock-absorbing effect and multi-functional technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of increasing transportation costs, bumps and vibrations, occupying space, etc., and achieve the control of heat absorption and cooling time , The process of wear and tear is slow and the service life is long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

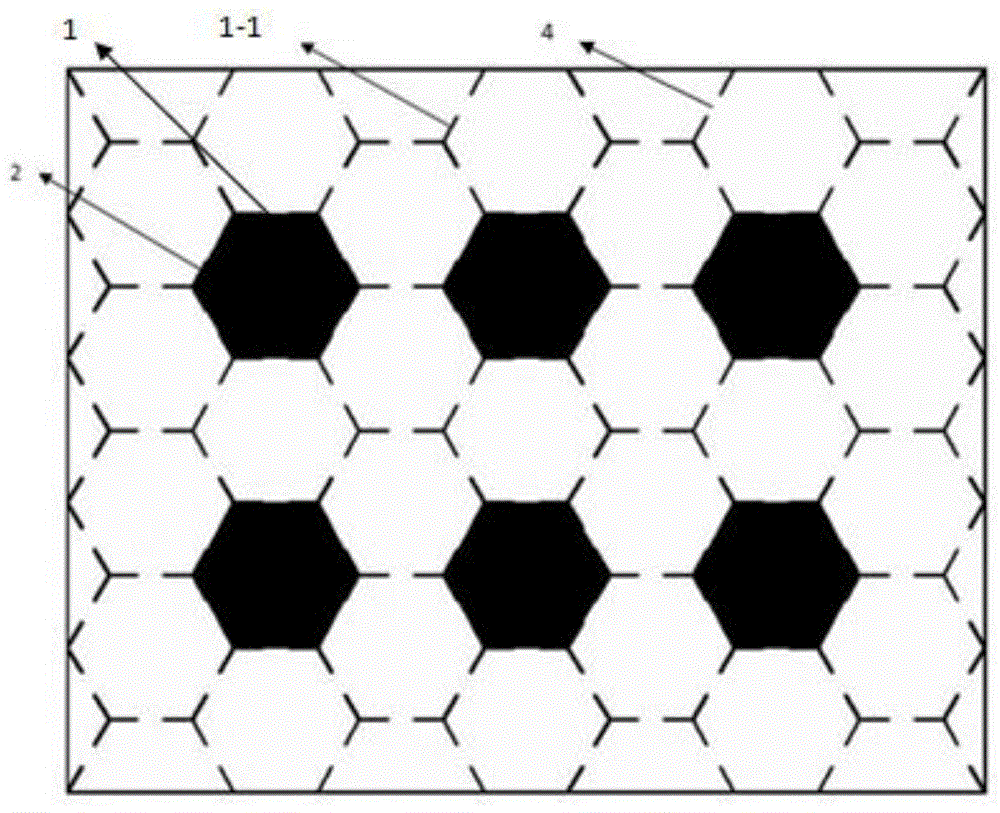

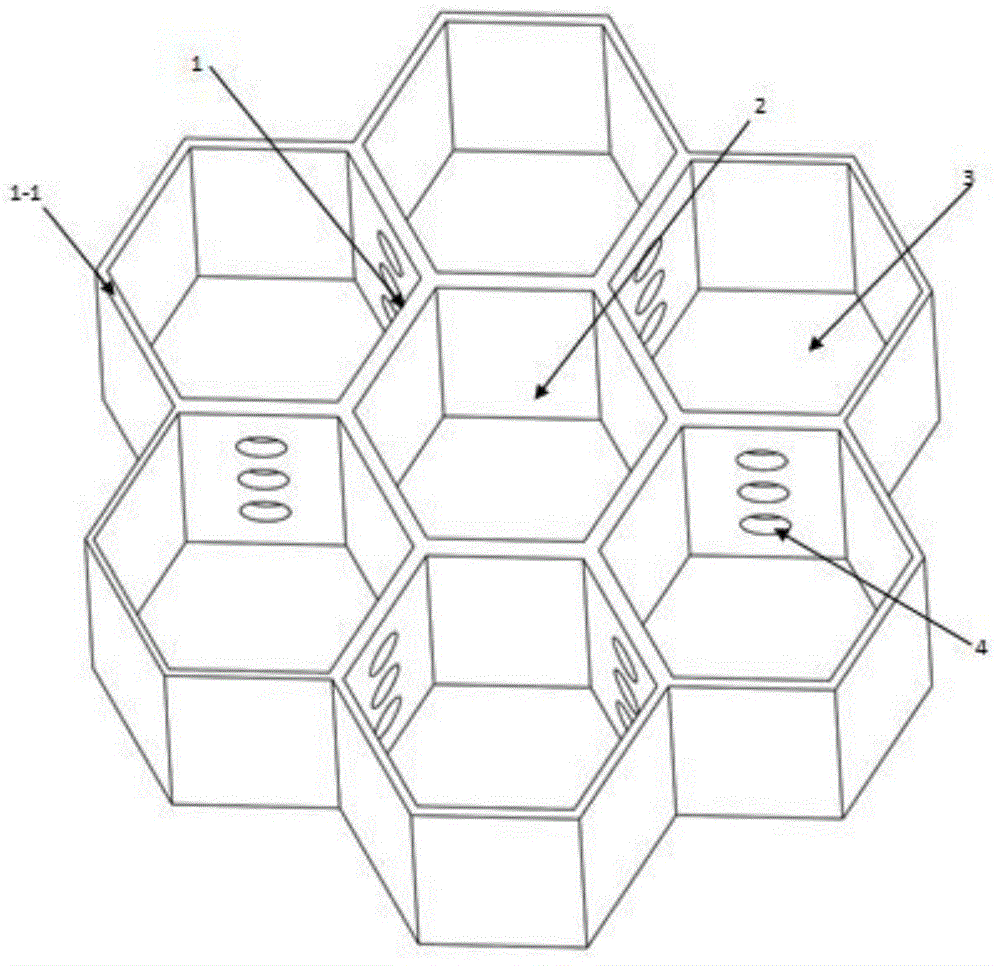

[0036] Such as figure 1 and figure 2 As shown, this embodiment is a multi-functional structure with heat-absorbing cooling and shock-absorbing effects. First, polyurethane is used to make the central frame 1 and the peripheral frame 1-1, and then ice sand is filled into the central frame 1 and the peripheral frame 1-1 as filler 2. In the spaced peripheral frame 1-1, three small holes 4 are arranged side by side on the side of the frame that is not filled, and finally the polyvinyl chloride material is used as the polymer material encapsulation layer 3 for encapsulation.

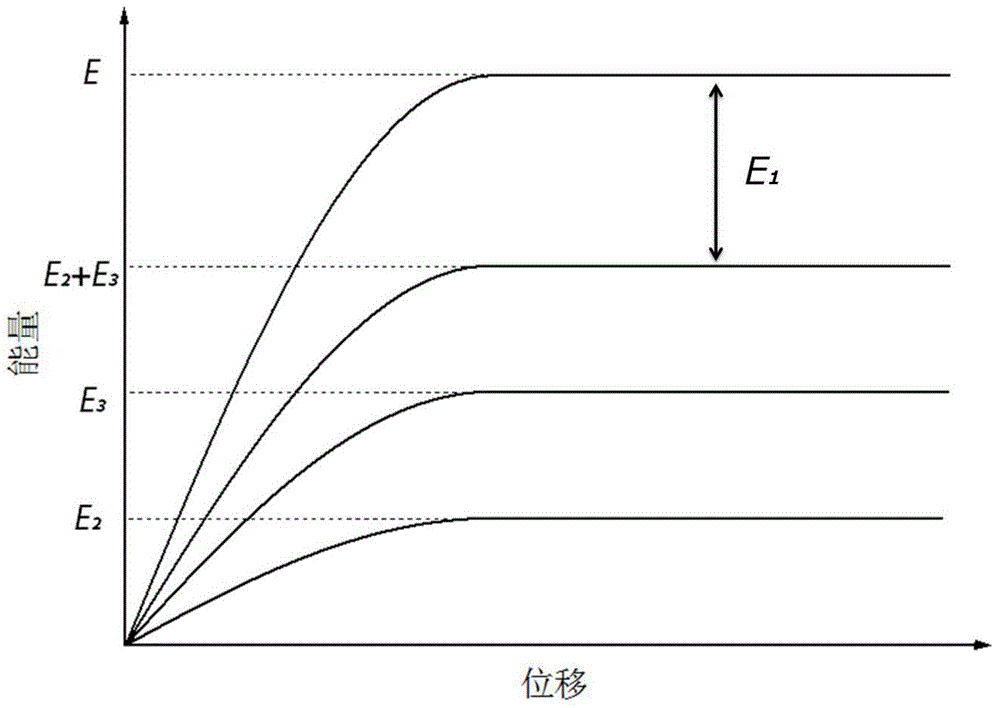

[0037] The ice sand used in this example is synthesized with natural minerals and various raw materials. It starts to absorb heat when the temperature is 30°C higher than the threshold temperature. When the ambient temperature is higher than 35°C, the ice sand will completely melt and lose heat. Cooling effect; when the threshold temperature is below 30°C, the melted ice sand will automatically crystallize ...

Embodiment 2

[0041] Such as figure 1 and figure 2 As shown, this embodiment is a multi-functional structure with heat absorption cooling and shock absorption effects. First, the central frame 1 and the peripheral frame 1-1 are made of polyester resin, and then ice mud is filled into the central frame as a filler 2. 1 and the spaced peripheral skeleton 1-1, and three small holes 4 are arranged side by side on the side of the skeleton that is not filled, and finally the polyurethane material is used as the polymer material encapsulation layer 3 for encapsulation.

Embodiment 3

[0043] Such as figure 1 and figure 2 As shown, this embodiment is a multifunctional structure with heat absorption cooling and shock absorption effects. First, the central skeleton 1 and the peripheral skeleton 1-1 are made of styrene-butadiene rubber, and then ice crystals are filled into the central skeleton 1 as filler 2 And in the spaced peripheral frame 1-1, three small holes 4 are arranged side by side on the side of the frame that is not filled. Finally, epoxy resin material is used as the polymer material encapsulation layer 3 for encapsulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com