A mixing and drying equipment for plastic particles

A technology of drying equipment and plastic particles, which is applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc. It can solve the problems of uniform mixing of materials, increased drying time, poor mixing effect, and reduced production efficiency, etc., to achieve Ensure drying and dehumidification, prevent particle leakage, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

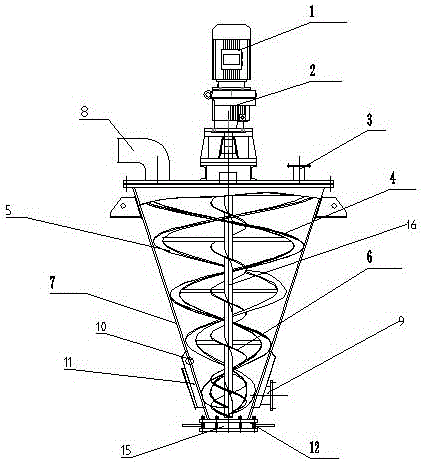

[0022] The main body of the present invention is a mixing and drying equipment for plastic particles, including a motor 1, a hardened reducer 2 and an inverted conical cylinder 7 with a built-in stirring shaft; the motor 1, a hardened reducer 2 and an inverted conical cylinder The bodies 7 are fixedly connected in turn. Experiments have proved that the stirring effect is not good, and the stirring speed is slow, which leads to the uniform mixing of materials and greatly increased drying time, which reduces production efficiency.

[0023] On the basis of the above-mentioned prior art, the present invention has been improved as follows: figure 1 As shown: the upper surface of the inverted conical cylinder 7 near the left end is provided with a feed inlet 3 and the bottom is provided with a discharge outlet 15, and the bottom outlet 15 is provided with a discharge valve 12; the inside of the inverted conical cylinder 7 is provided with an outer Layer helix and inner layer helix....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com