Device and method for testing elasticity modulus under high temperature and ultrahigh temperature environments

A technology of elastic modulus and test method, which is applied in measuring devices, using stable tension/pressure to test the strength and strength characteristics of materials, etc. The effect of quantitative performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

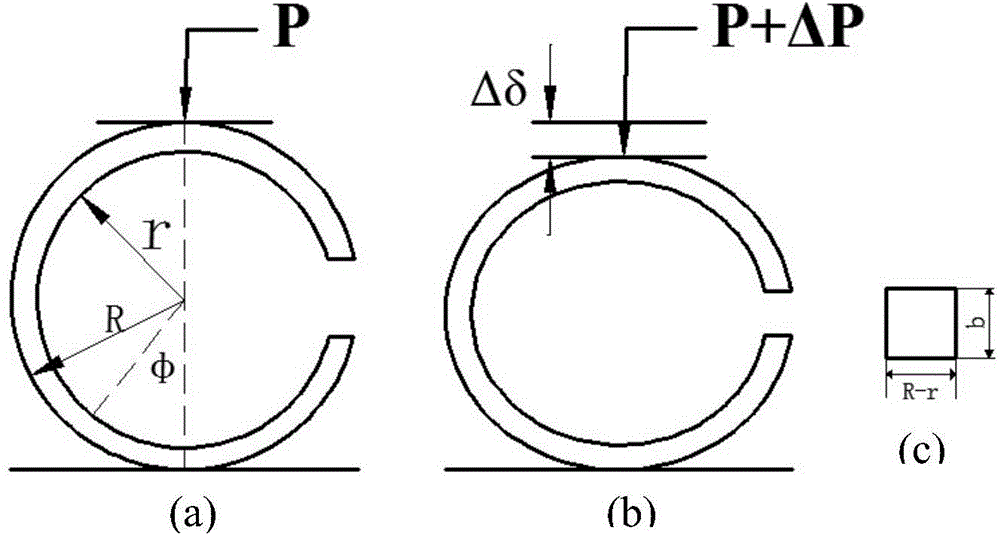

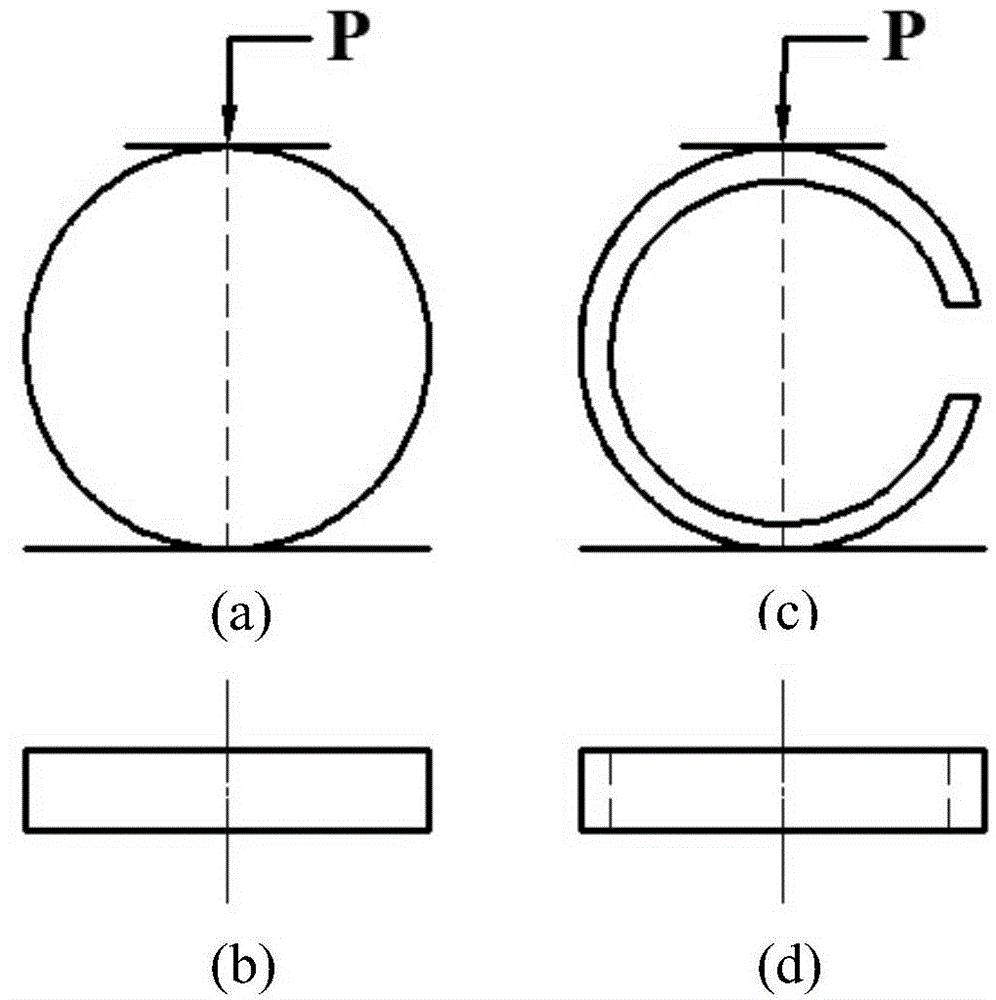

[0078] Embodiment 1: Measuring the elastic modulus of quartz glass material under high temperature atmospheric environment

[0079] Specimen preparation: Use a wire cutting machine to cut the quartz glass pipe (outer diameter 48mm, inner diameter 43mm) into several gap ring specimens with a width of 7.5mm, then polish and chamfer the surface; then cut out the gap ring specimens A horizontal notch with a length of 10mm. Then process a quartz glass disc (diameter 50 mm, width 8 mm) similar in size to the notch ring test piece for correction.

[0080] The specific experimental operation steps are:

[0081] ①Take a notched ring test piece and measure its size as 47.87mm (outer diameter D=2R), 42.76mm (inner diameter d=2r), 7.74mm (width b);

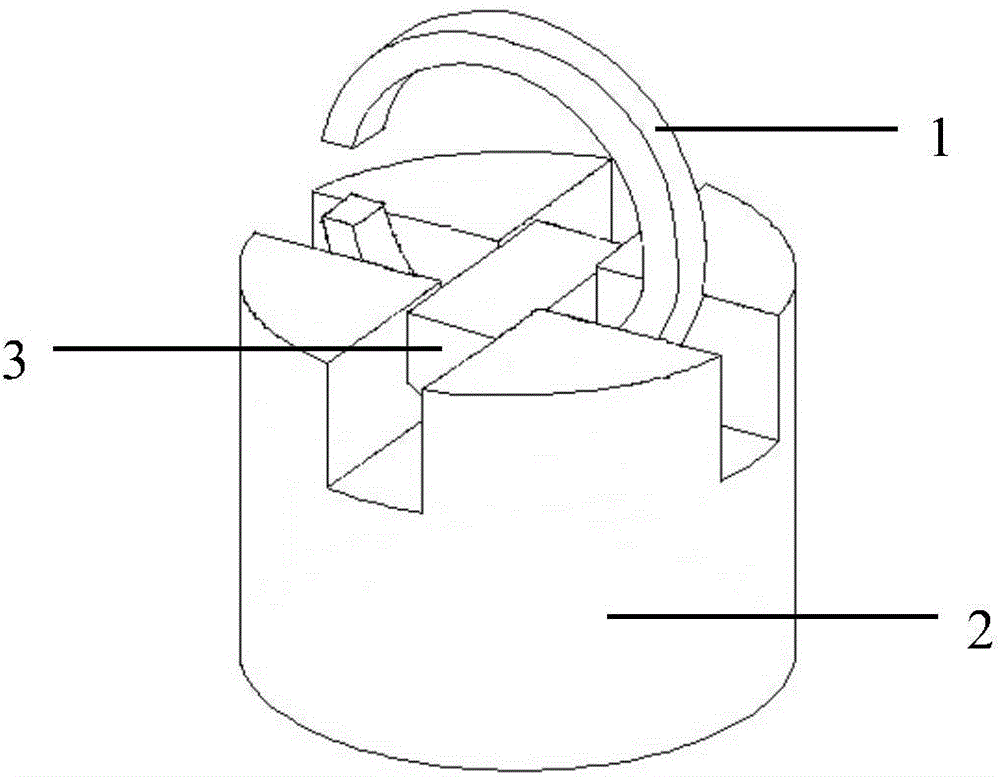

[0082] ② Place the test piece on the designed cross-recessed fixture (see image 3 ), and then placed in a silicon molybdenum rod heating furnace, heated from room temperature (17°C) to 600°C, 800°C, 1000°C, 1100°C and 1200°C in sequence...

Embodiment 2

[0089] Embodiment 2: Measuring the elastic modulus of corundum ceramic material in ultra-high temperature vacuum environment

[0090] Specimen preparation: use a wire cutting machine to cut corundum high-temperature-resistant pipes (outer diameter 40mm, inner diameter 34mm) into several notched ring specimens with a width of 8mm, polish and chamfer the surface; then cut out a horizontal notch on the ring , the notch length is 9mm. Then process a graphite disc (diameter 40mm, width 8mm) similar in size to the gap ring for correction.

[0091] The specific experimental operation steps are:

[0092] ①Take a notched ring test piece and measure its size as 39.94mm (outer diameter D=2R), 33.96mm (inner diameter d=2r), 7.90mm (width b);

[0093] ② Place the test piece on the designed cross-recessed fixture (see image 3 ), and then put it into a graphite heating furnace, vacuumize it first, and heat it from room temperature (17°C) to 1000°C, 1300°C, 1500°C, 1600°C and 1700°C in se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com