Gate structure of separation gate power device and process method

A power device and gate structure technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as complex process, reduced product performance, deterioration, etc., to reduce diffusion effects, solve connection problems, and have no pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

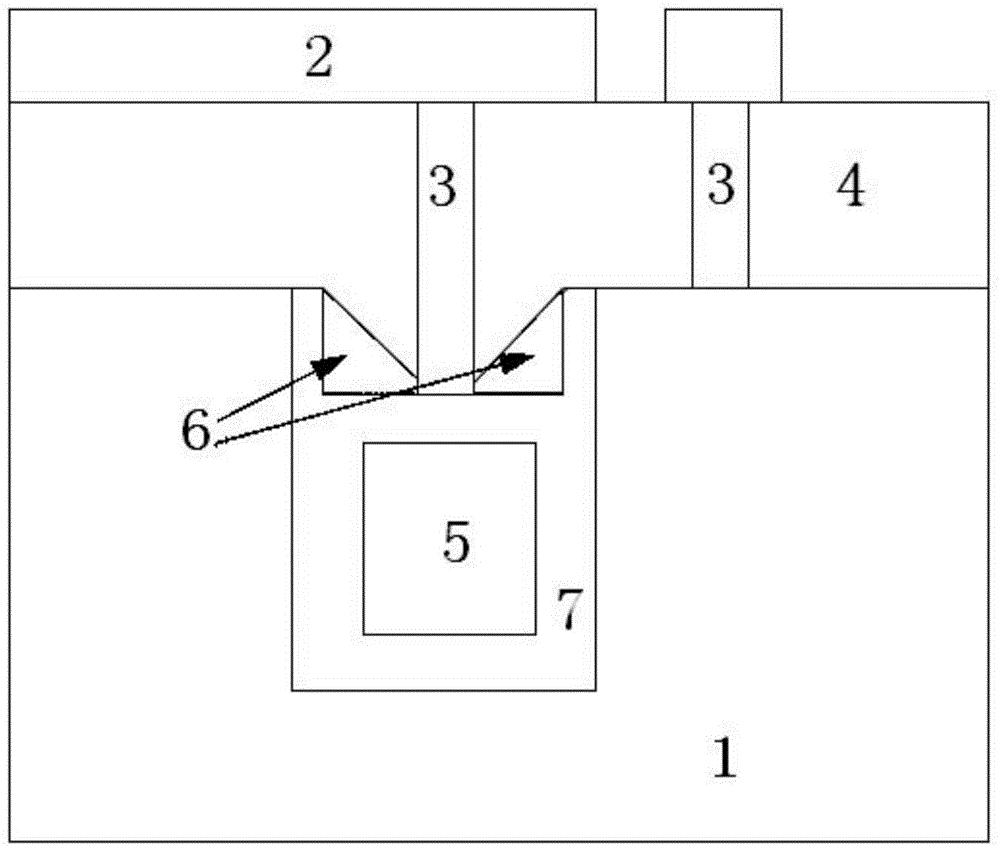

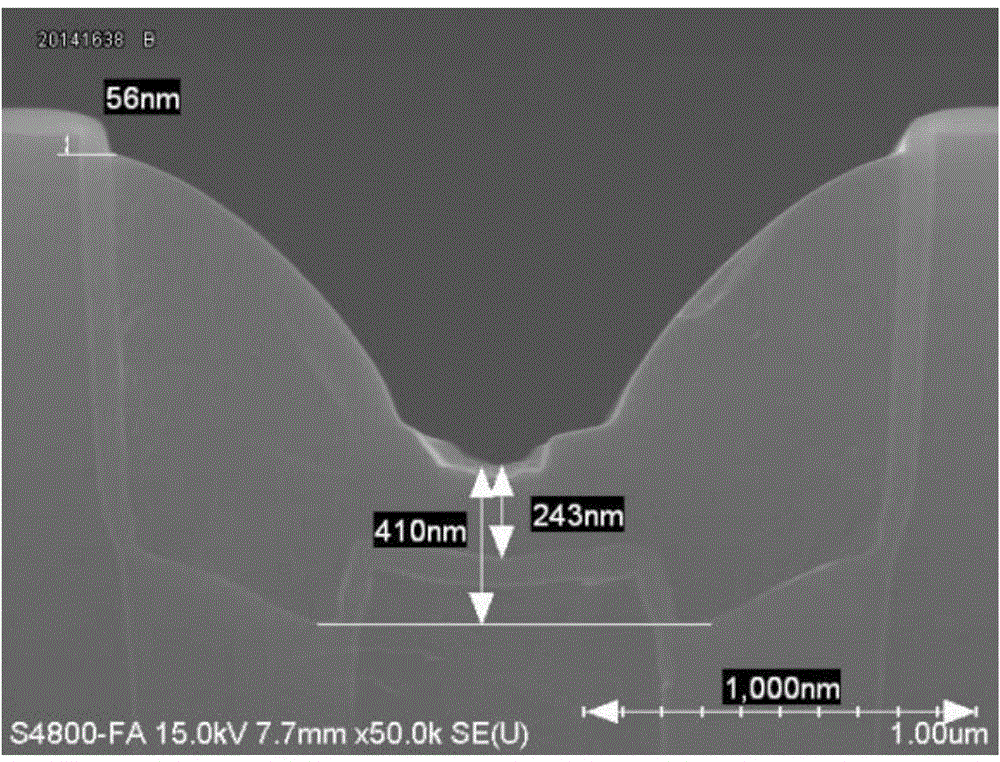

[0032] The gate structure of the split-gate power device described in the present invention, such as Figure 9 As shown, there is a trench on the silicon substrate 1, and a layer of oxide layer 7 is attached to the side wall and bottom of the trench. The lower part of the trench has a separate gate 5, and the upper part of the separate gate 5 is also covered with a layer of silicon oxide. The silicon oxide layer on the side wall of the groove and the bottom of the groove together form the separation gate, the upper part of the trench is the gate 6, the surface of the silicon substrate 1 is the interlayer dielectric, and the metal lead 2 connects the gate through the contact hole 3 passing through the interlayer dielectric 4. Pole 6 leads out. The gate 6 is a polysilicon thin gate with a U-shaped structure, and its interior is filled with metal tungsten 8 . The contact hole 3 is connected with the filled metal tungsten 8 to lead out the gate 6 .

[0033] Between the polysilico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com