Transforming lens generating Bessel wave beams

A Bessel beam and lens technology, applied in the field of lenses, can solve the problems of difficult processing, difficult installation and storage, difficult to reach tools, etc., to achieve easy installation and storage, easy processing, and difficult installation and storage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

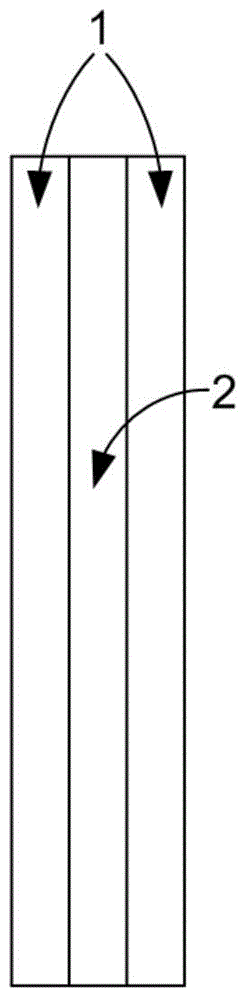

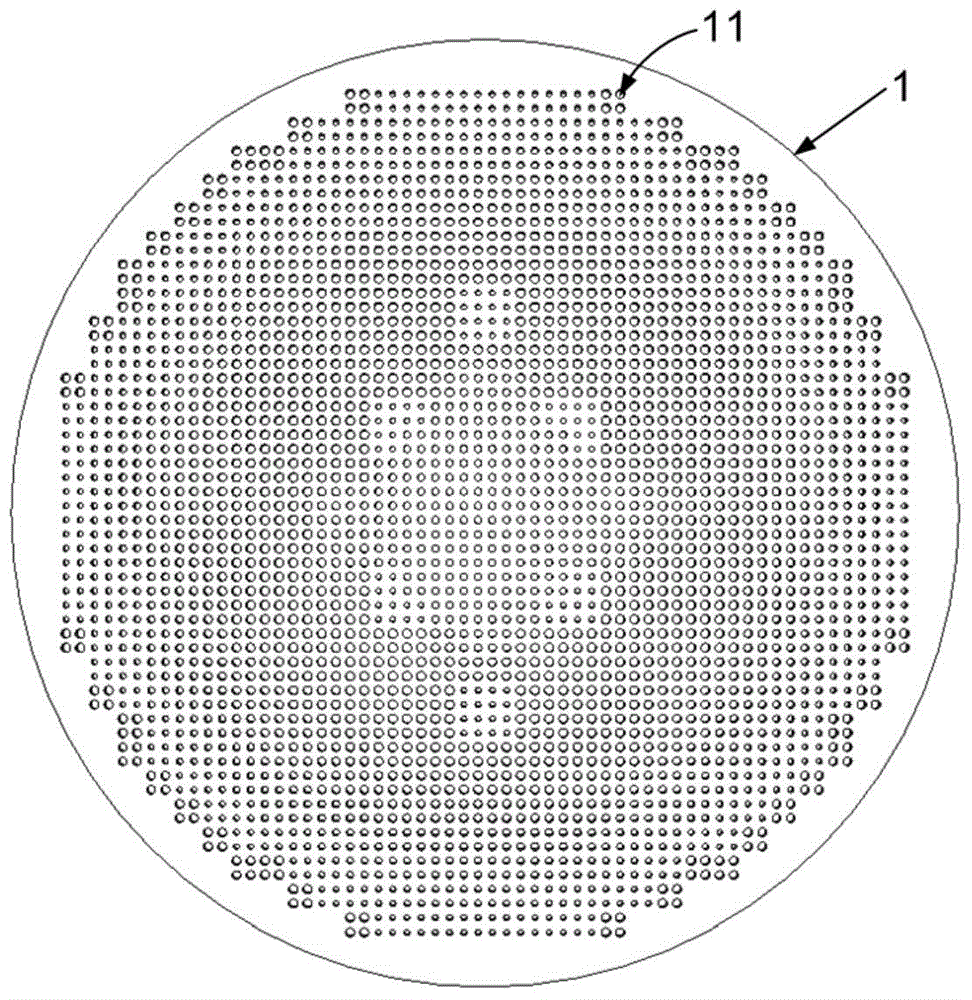

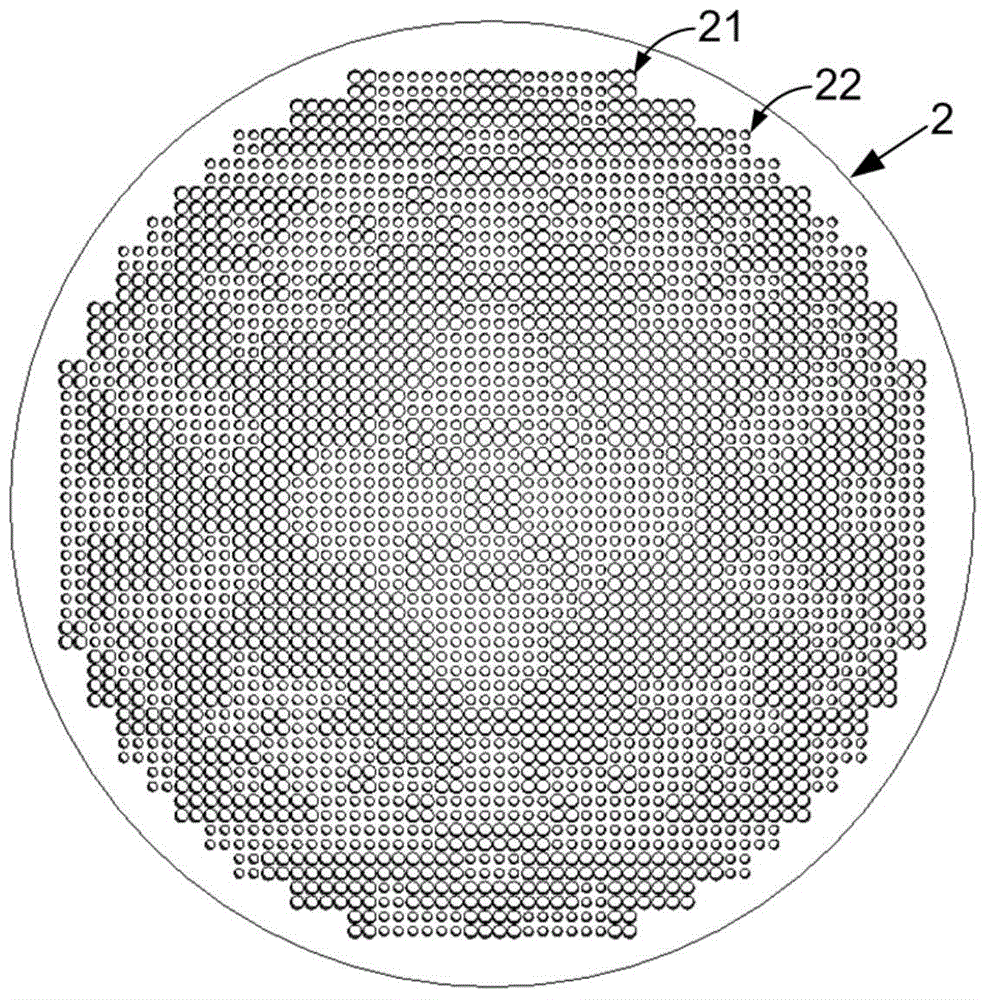

[0035] This embodiment is a conversion lens that transforms the incident Gaussian beam to generate a zero-order Bessel beam. The conversion lens has a three-layer structure, such as figure 1 . The transformation lens that produces the Bessel beam includes an outer layer dielectric lens 1 and a core layer dielectric lens 2, both of which are discs with a diameter of 50 mm, and the outer layer dielectric lens 1, the core layer dielectric lens 2, and the outer layer dielectric lens 1 The sequence is placed coaxially and side by side. The dielectric constant of the outer layer dielectric lens 1 is 2.2, which is smaller than the dielectric constant of the core layer dielectric lens 2. The dielectric constant is 6.15. The thickness of the outer layer dielectric lens 1 is 3.175 mm. There is a square grid with side length 1.5 mm, such as Figure 4 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com