Method of manufacturing antimicrobial examination gloves

A manufacturing method and technology of gloves, which can be used in gloves, surgical gloves, surgery, etc., can solve the problems of skin irritation and dry gloves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

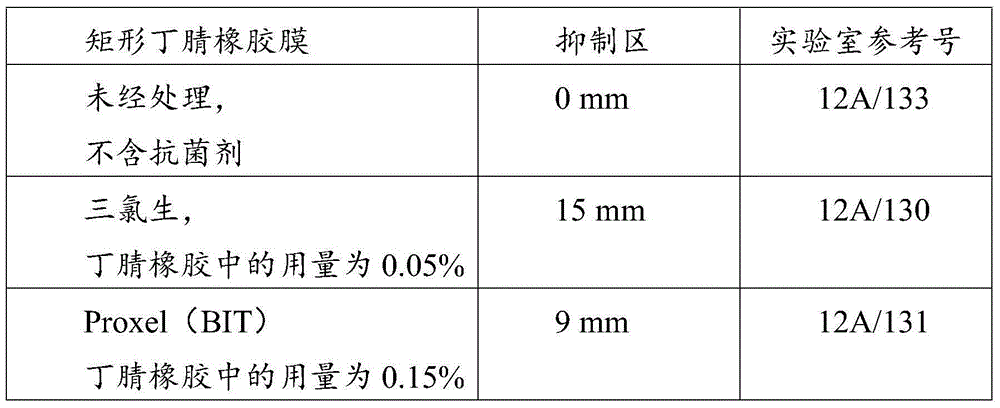

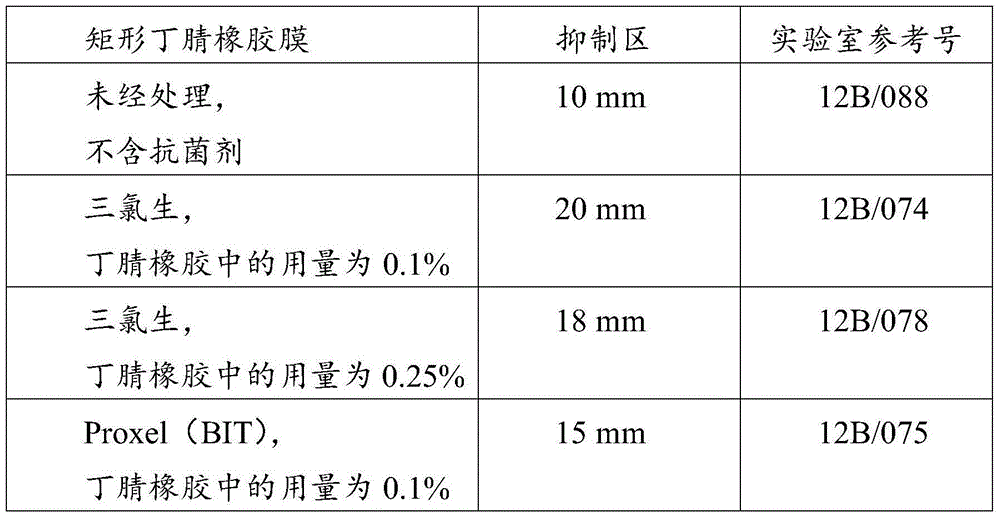

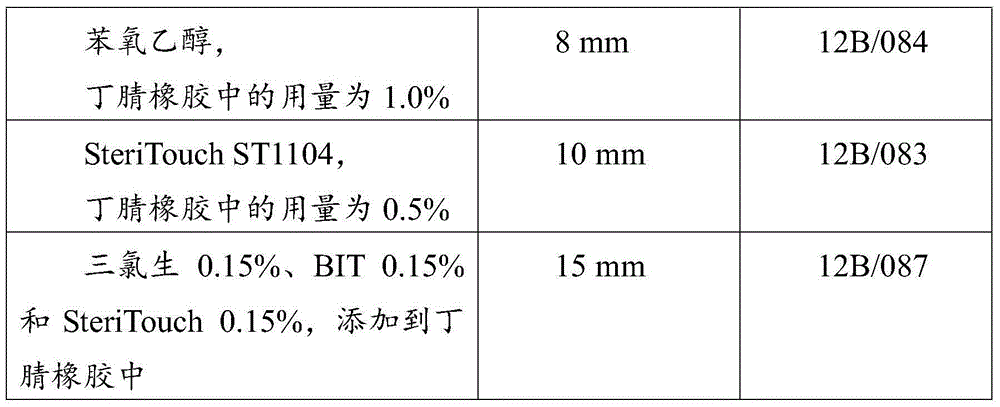

[0076] Trials were carried out to investigate which combination of antimicrobial agents was compatible with the glove manufacturing process and had the best antimicrobial performance. The method for preparing a small rectangular nitrile rubber latex is: immerse a clean microscope slide in a warm coagulant solution, lift it up and put it in an oven for drying, and set the oven temperature to 110°C. The slides were removed from the oven to cool and immersed in the nitrile rubber latex suspension. Then lift it up to drain the remaining liquid, put it into an oven, and set the temperature at 110°C. After the cured nitrile layer has cooled, it is carefully removed from the microscope slide and sent for testing to determine antimicrobial properties. The appropriate amount of active ingredient is added to the coagulated suspension and the nitrile polymer latex suspension.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com