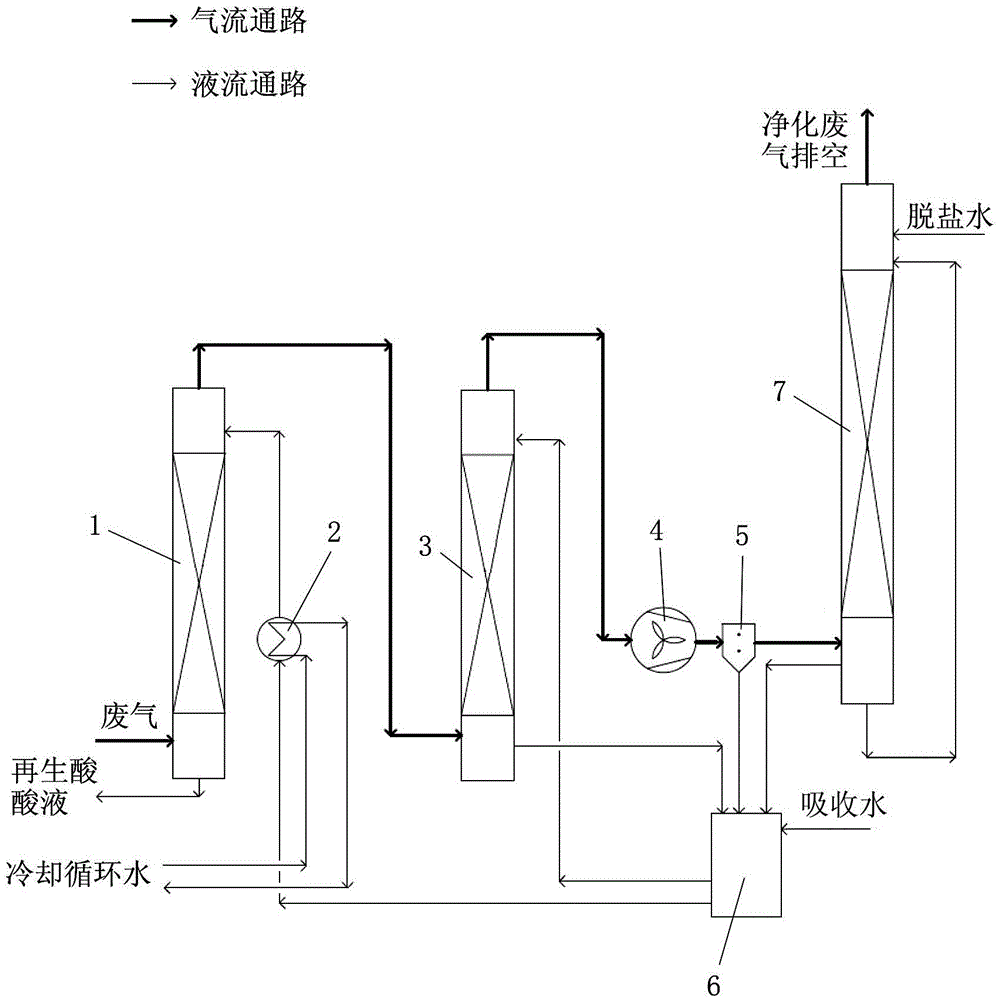

Acid regeneration acid gas absorption and exhaust emission reduction system and utilization method thereof

An acid regeneration and acid gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as insufficient development and optimization attention, and achieve the effect of reducing pollution and harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Waste acid treatment capacity 3.5m 3 / h acid regeneration unit, the inlet temperature of the primary absorption tower is 88-96°C. Intake volume is 8700~9500Nm 3 / h, the instant spray volume is about 3.5m 3 / h of absorbed water. The area of the round hole type acid-resistant graphite heat exchanger is 20m 2 The cooling capacity is about 190,000Kcal / h (equivalent to 50,000kcal to 60,000kcal for every cubic meter of acid liquid regenerated). The outlet gas temperature of the primary absorption tower is 65-70°C, and the outlet gas temperature of the exhaust gas scrubber is about 60°C, which meets the standard discharge. Compared with the conventional acid regeneration process, the discharge temperature of exhaust gas is reduced by 13-18°C, and the amount of exhaust gas is reduced by nearly 20%.

Embodiment 2

[0045] Waste acid treatment capacity 4m 3 / h acid regeneration unit, the intake temperature of the primary absorption tower is 88-96°C, and the intake air volume is 9000-11000Nm 3 / h, the average spray volume of the absorption level at the top of the tower is about 4m 3 / h. The material of the heat exchanger is made of acid-resistant and temperature-resistant F4 (polytetrafluoroethylene), and the area of the cooler is 28m 2 , The cooling capacity is about 210000Kcal / h (equivalent to 50000kcal~60000kcal for every cubic meter of acid liquid regenerated). The gas temperature at the outlet of the first-stage absorption tower is 10-15°C lower than that of the original process, and the outlet gas temperature of the exhaust gas scrubber is about 60°C, meeting the emission standard. Compared with the existing technology, the discharge temperature of exhaust gas is reduced by 13-16°C, and the amount of exhaust gas is reduced by 16-18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com