Regeneration method of expired scr denitrification catalyst

A denitrification catalyst and active technology, applied in the field of denitrification catalysis, can solve the problems of inability to regenerate the catalyst, inability to comprehensively treat the catalyst, and incomplete removal of surface deposits, etc., and achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: (1) Purge: Use clean and dry compressed air to purge the invalid SCR denitrification catalyst to clean the solid particles and dust on the surface of the catalyst; (2) Heat treatment: Purge the SCR Put the denitrification catalyst in a muffle furnace for heat treatment at 300°C for 2 hours to remove easily decomposed substances adsorbed on the surface such as carbon deposits, sulfur deposits and metal deposits; (3) Washing: put the heat-treated SCR denitrification catalyst into deionized Soak in water until the ion concentration in deionized water is stable, and initially remove the metals and salts precipitated on the surface of the catalyst; (4), pickling: place the washed SCR denitration catalyst in a mixed solution of 10wt% sulfuric acid and 5wt% hydrofluoric acid , ultrasonically dispersed for 2 hours to further remove metals and salts precipitated on the surface of the catalyst; (5), active regeneration: soak the acid-washed SCR denitration catalyst in a...

Embodiment 2

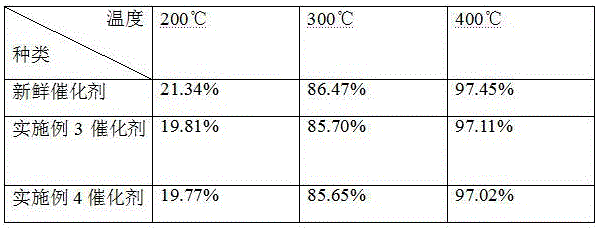

[0016] The difference between Example 2 and Example 1 is that the purging of step (1) is carried out in a closed negative pressure environment, so that the effect of removing solid particles and dust on the surface of the catalyst is better. When the solid particles and dust are pushed by compressed air After leaving the catalyst surface, it will not fall back to the catalyst surface due to gravity to form secondary pollution. The catalyst of Example 2 and the catalyst of Example 1 are compared in activity, and the specific data are shown in the following table:

[0017]

[0018] It can be seen that the activity of Example 2 is slightly higher than that of Example 1.

Embodiment 3

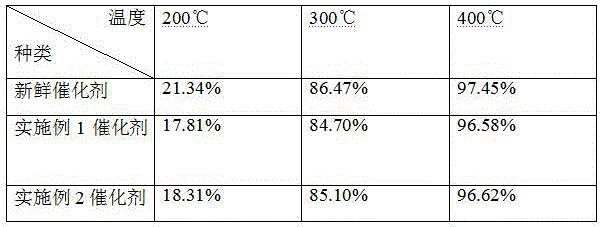

[0019] Preferred embodiment 3: (1) Purge: Use clean and dry compressed air to purge the expired SCR denitration catalyst; (2) Heat treatment: Put the purged SCR denitration catalyst into a muffle furnace at 300°C Heat treatment for 2 hours; (3) Washing: Soak the heat-treated SCR denitrification catalyst in deionized water, change the deionized water every 15 minutes, take samples to detect the ion content in the washing water, until the ion concentration in the deionized water is stable, Electrify in deionized water with a current of 5A; (4), pickling: place the washed SCR denitration catalyst in a mixed solution of 10wt% sulfuric acid and 5wt% hydrofluoric acid, and ultrasonically disperse it for 2 hours; (5), active regeneration: put The acid-washed SCR denitration catalyst was immersed in an active mixed solution containing 5wt% ammonium paratungstate and 1wt% ammonium metavanadate for 2 hours, and then it was taken out and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com