Honeycomb denitration catalyst for flue gas at 400 DEG C-600 DEG C and preparation method of honeycomb denitration catalyst

A technology of denitration catalyst and catalyst coating, which is applied in the direction of catalyst activation/preparation, molecular sieve catalyst, chemical instruments and methods, etc., can solve the deactivation of denitration catalyst and other problems, and achieve high loading capacity, high out-of-stock activity, and good tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

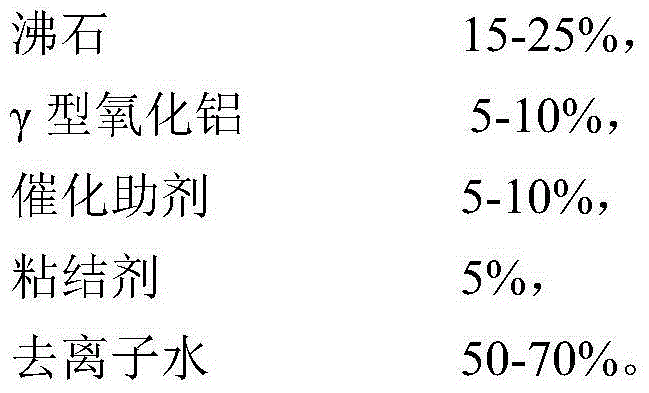

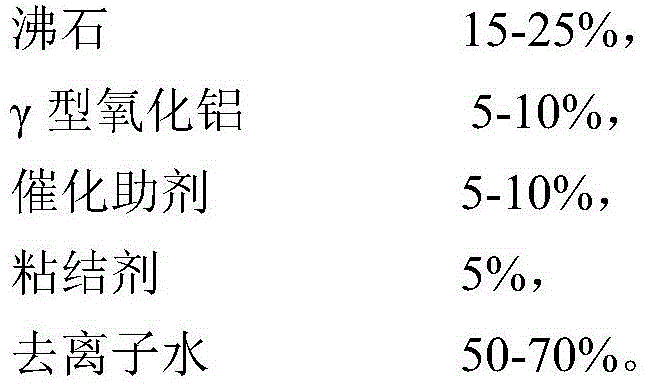

[0030] (1) 15% zeolite, 5% γ-alumina, 5% catalytic promoter, 5% binder and 70% deionized water by mass percentage, weigh 15g ZSM-5 type zeolite molecular sieve, 5g γ-alumina, 5g catalytic promoter (comprising ammonium molybdate, cerium nitrate, ferrous chloride, ammonium tungstate and chloroplatinic acid, wherein by molar ratio Mo:Ce:Fe:W:Pt=60:200:80:120:1) , 5g binding agent (iron nitrate) and 70g deionized water, fully stirred in a stirrer until uniform;

[0031] (2) The above-mentioned mixed solution is moved into a ball mill, and the coating slurry is obtained after sufficient ball milling, and the ball milling time is 24 hours;

[0032] (3) repeatedly immersing the honeycomb ceramics in the above-mentioned coating slurry, the immersion time is 5 minutes, and then blowing the excess coating slurry on the surface of the honeycomb ceramics by high-pressure air;

[0033] (4) Dry the coated honeycomb ceramics at 120°C for 12 hours, and then bake at 500°C for 5 hours to obtai...

Embodiment 2

[0036] (1) By mass percentage 25% zeolite, 10% γ-alumina, 10% catalytic aid, 5% binder and 50% deionized water, weigh 25g A-type zeolite molecular sieve, 10g γ-alumina, 10g catalytic Additives (including ammonium molybdate, cerium nitrate, ferrous chloride, ammonium tungstate, chloroplatinic acid and palladium nitrate, wherein the molar ratio Mo: Ce: Fe: W: Pt: Pd = 20: 160: 120: 140 : 1:1), 5g binder (cerium nitrate) and 50g deionized water, fully stir in a stirrer until uniform;

[0037] (2) The above-mentioned mixed solution is moved into a ball mill, and the coating slurry is obtained after sufficient ball milling, and the ball milling time is 36 hours;

[0038] (3) repeatedly immersing the honeycomb ceramics in the above-mentioned coating slurry, the immersion time is 10 minutes, and then blowing the excess coating slurry on the surface of the honeycomb ceramics by high-pressure air;

[0039] (4) Dry the coated honeycomb ceramics at 120°C for 12 hours, and then bake at 5...

Embodiment 3

[0042] (1) By mass percentage 20% zeolite, 7.5% γ-alumina, 7.5% catalytic aid, 5% binder and 60% deionized water, weigh 20g X-type zeolite molecular sieve, 7.5g γ-alumina, 7.5 g catalytic promoter (including ammonium molybdate, cerium nitrate, ferrous chloride, ammonium tungstate, chloroplatinic acid and palladium nitrate, wherein the molar ratio Mo: Ce: Fe: W: Pt: Pd = 60: 200: 160 : 160:1:1), 5g of binder (including cerium nitrate and ferric nitrate, wherein the molar ratio Ce:Fe=5:1) and 60g of deionized water are fully stirred in a stirrer until uniform;

[0043] (2) The above-mentioned mixed solution is moved into a ball mill, and the coating slurry is obtained after sufficient ball milling, and the ball milling time is 48 hours;

[0044] (3) repeatedly immersing the honeycomb ceramics in the above-mentioned coating slurry, the immersion time is 15 minutes, and then blowing the redundant coating slurry on the surface of the honeycomb ceramics by high-pressure air;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com