Denitration catalyst and preparation method thereof

A technology of denitrification catalyst and oxide, applied in the field of denitrification catalyst, can solve the problems of pollution and toxicity, and achieve the effect of expanding application range, high activity of out-of-stock, and non-toxic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

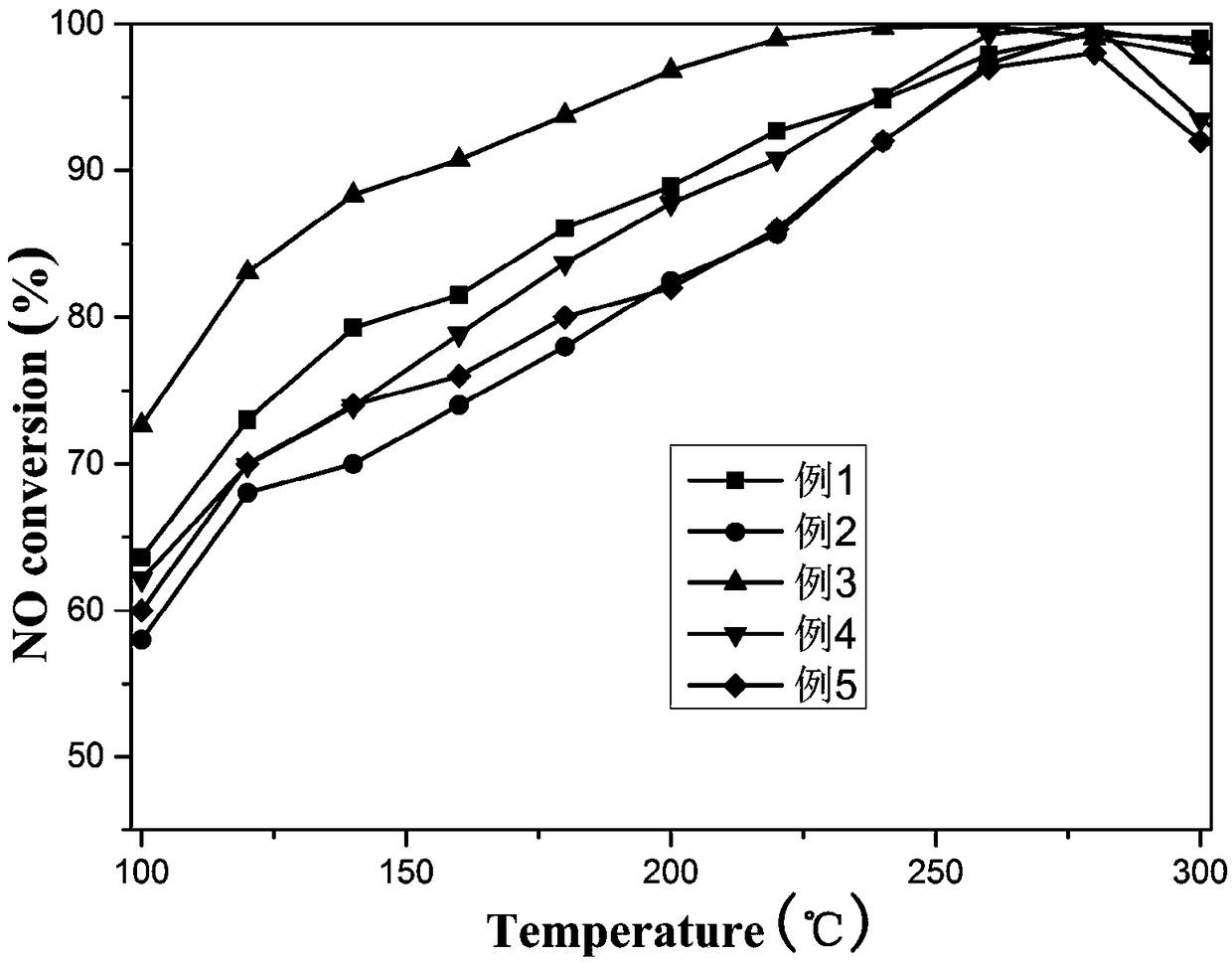

Examples

Embodiment 1

[0029] S1. Preparation of Ti sol: Take 50wt% tetrabutyl titanate, 3.5wt% F127, and absolute ethanol, mix them and place them in a 50kHz ultrasonic wave and stir them for 2 hours. After stirring, take 6wt% deionized water and add them dropwise to the above Mix the solution and place it in a 50kHz ultrasonic wave to continue stirring for 0.5h;

[0030] S2. Immerse the honeycomb ceramics with a pore diameter greater than 50nm into the Ti sol treated in step S1 and place them together in an environment with a temperature of 10°C for 4 hours, then take out the foam ceramics and place them in a vacuum drying oven for 4 hours at a drying temperature of 105 °C, during the drying process, place the sample in a rotator and keep turning it up and down at a constant speed of 50 rpm, and repeat this step 3 times;

[0031] S3. Active material preparation: respectively 25wt% Fe(NO 3 ) 3 9H 2 O, 7wt%Ce(NO 3 ) 3 ·6H 2 O and 8wt%Sm(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to m...

Embodiment 2

[0036] S1. Preparation of Ti sol: Take 70wt% tetrabutyl titanate, 0.5wt% F127, and absolute ethanol, mix them and place them in a 60kHz ultrasonic wave for 2.5 hours. After stirring, take 8wt% deionized water and add them dropwise to the above Mix the solution and place it in a 60kHz ultrasonic wave to continue stirring for 0.5h;

[0037] S2. Immerse the honeycomb ceramics with a pore diameter greater than 50nm into the Ti sol treated in step S1 and place them together in an environment with a temperature of 10°C for 5 hours, then take out the foam ceramics and place them in a vacuum drying oven for 6 hours at a drying temperature of 110°C. °C, during the drying process, place the sample in a rotator and keep turning it up and down at a constant speed of 60 rpm, and repeat this step 3 times;

[0038] S3. active material preparation: respectively 15wt% Fe(NO 3 ) 3 9H 2 O, 2wt%Ce(NO 3 ) 3 ·6H 2 O and 3wt%Sm(NO 3 ) 3·6H 2 O was dissolved in deionized water to make a mixe...

Embodiment 3

[0043] S1. Preparation of Ti sol: Mix 68wt% tetrabutyl titanate, 2wt% F127, and absolute ethanol respectively and place them in a 70kHz ultrasonic wave to stir for 3 hours. After stirring, add 10wt% deionized water to the above mixed solution drop by drop And placed in 70kHz ultrasonic wave to continue stirring for 1h;

[0044] S2. Immerse the honeycomb ceramics with a pore diameter greater than 50nm into the Ti sol treated in step S1 and place them together in an environment with a temperature of 20°C for 6 hours, then take out the foamed ceramics and place them in a vacuum drying oven for 8 hours at a drying temperature of 120°C °C, during the drying process, place the sample in a rotator and keep turning it up and down at a constant speed of 70 rpm, and repeat this step 3 times;

[0045] S3. Active material preparation: respectively 20wt% Fe(NO 3 ) 3 9H 2 O, 5wt% Ce(NO 3 ) 3 ·6H 2 O and 5wt%Sm(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to make a mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com