Reduction casting compositing method and device for large iron ingots

A composite device and steel ingot technology, which is applied in the reduction casting composite method and device field of large steel ingots, can solve the problems of difficult fixing of rods and cumbersome cloth distribution, and achieve the elimination of heating process, increase of solidification speed, avoidance of secondary oxidation and inhalation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

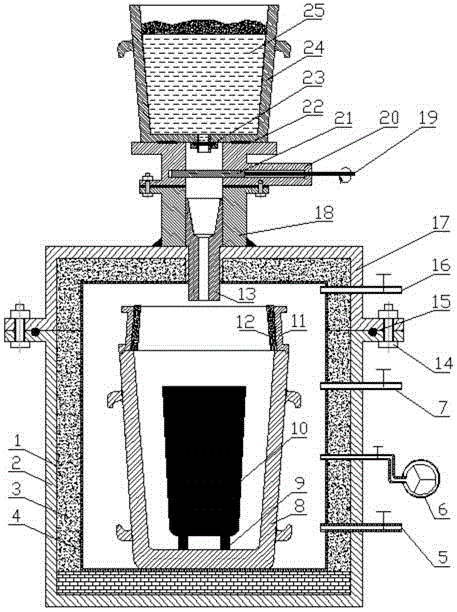

[0027] like figure 1 As shown, a reduction casting compound method for large steel ingots is adopted, and large steel ingots of 125 to 130 tons are produced in one reduction casting process. The content of the method is as follows:

[0028]Select the steel ingot with the weight of 50 tons to do the core blank 10, the composition of the core blank 10 is 45# steel, the shape of the core blank 10 is a regular octagon, and the cap mouth part is cut off after the core blank 10 is demoulded, and then cooled When the temperature reaches 800° C. to 850° C., high-pressure nitrogen gas is used to blow off the thick primary iron oxide scale on the surface of the core blank 10 . Put the steel ingot mold 8 of 130 tons of large steel ingot into the furnace body 1, place 4 pieces of cylindrical pad iron 9 with a diameter of 60 mm and a height of 100 mm and a composition of 45# steel at the bottom of the steel ingot mold 8, requiring that the surface of the pad iron 9 has no oxidation The ir...

Embodiment 2

[0030] like figure 1 As shown, a large steel ingot reduction casting compound method is adopted, and a large steel ingot of 180 to 190 tons is produced by secondary reduction casting compounding. The content of the method is as follows:

[0031] Select a forged rectangular steel billet with a weight of 40 tons as the core blank 10. The composition of the core blank 10 is 45# steel. First, the core blank 10 is heated to 900 ° C, and the surface of the core blank 10 is blown off by high-pressure nitrogen. primary oxide scale. Put the steel ingot mold 8 of 85 tons of large steel ingot into the furnace body 1, place 4 pieces of cylindrical pad iron 9 with a diameter of 100 mm and a height of 120 mm and a composition of 45# steel at the bottom of the steel ingot mold 8. The surface of the pad iron 9 is required to be free of oxidation The iron sheet is preheated to 150°C, and then the core blank 10 is put into the steel ingot mold 8 by a crane, supported by the pad iron 9, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com