Dephosphorizing method for acid vanadium leached solution

A leachate and acid technology, applied in the field of dephosphorization treatment, can solve the problems of complex process and insufficient phosphorus removal rate, and achieve the effects of simple process, high phosphorus removal rate and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

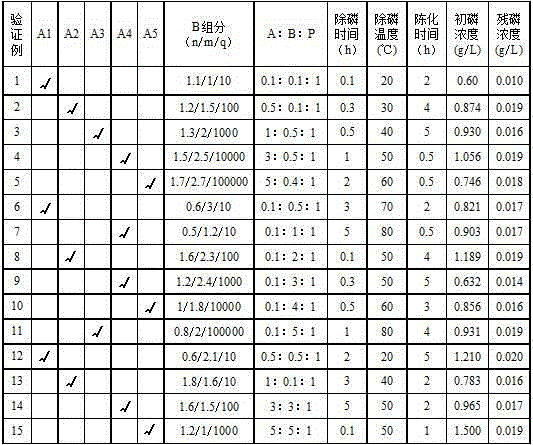

Examples

Embodiment Construction

[0009] A method for removing phosphorus in acidic vanadium leaching solution. In the present invention, the pH value of the acidic vanadium leaching solution is 2.5 to 4.0, and the concentration of phosphorus is 0.6g / L to 1.5g / L; the phosphorus removal agent used during phosphorus removal is composed of A component and B component Composite dephosphorization agent, A component is Al 2 (SO 4 ) 3 (aluminum sulfate), MgSO 4 (magnesium sulfate), CaSO 4 (calcium sulfate), SrSO 4 (strontium sulfate) and ZnSO 4 (Zinc sulfate), the B component is [Fe(OH) n (SO 4 ) m ] q (polyferric sulfate), in [Fe(OH) n (SO 4 ) m ] q Among them, 0.5≤n≤2, 1≤m≤3, 10≤q≤100000; the steps of the phosphorus removal method are as follows:

[0010] (1) Add a composite dephosphorization agent to the acidic vanadium leaching solution, and control the temperature between 20°C and 80°C to fully stir to carry out the phosphorus removal reaction; The molar ratio of phosphorus in the leaching solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com