Modification finishing process of cellulose fibre fabric

A cellulose fiber and fabric technology, applied in the field of cellulose fiber fabric modification and finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A cellulose fiber fabric modification finishing process disclosed by the present invention, the steps are as follows:

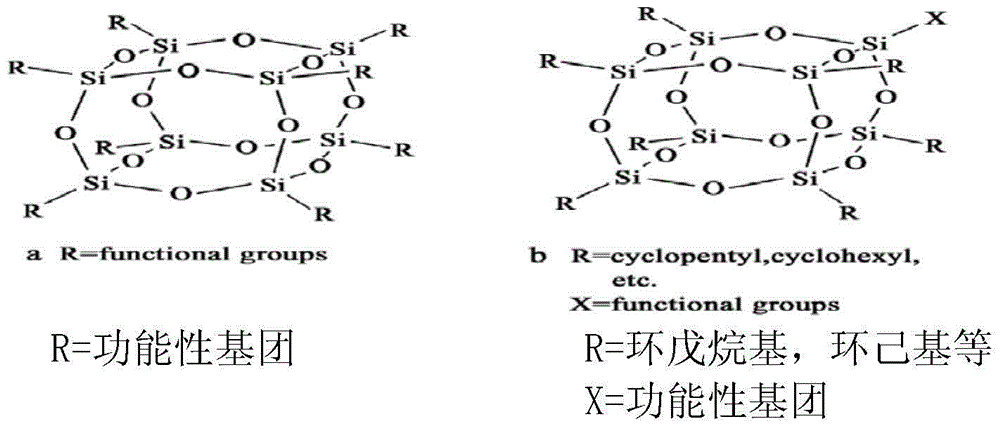

[0034] The first step is to use γ-aminopropyl triethoxysilane as raw material, through acidification catalysis, hydrolysis and condensation, to synthesize polyγ-aminopropyl silsesquioxane (POSS) with a caged structure containing octaamino groups. -NH 2 ).

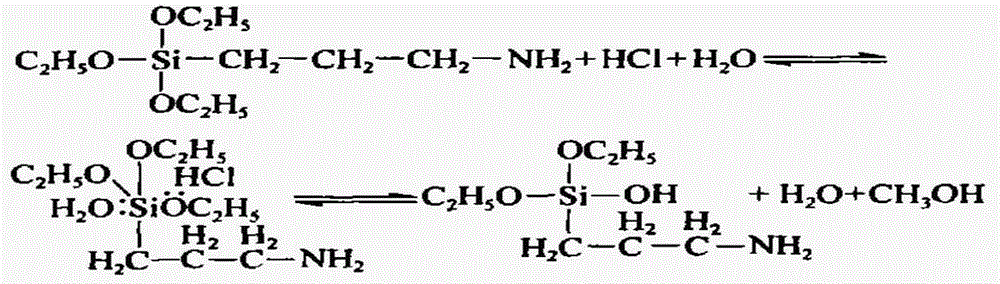

[0035] Hydrolysis and condensation reactions:

[0036]

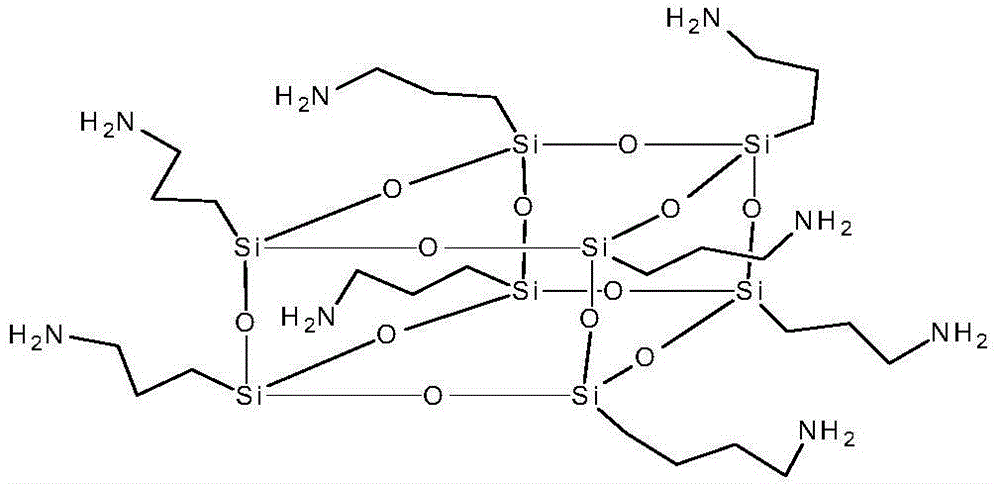

[0037] When Si-OH and Si-OH collide, a nucleophilic attack occurs, the water molecules are removed to complete the condensation process, and Si-O-Si bonds are formed. By controlling the process conditions of hydrolysis and condensation, POSS with a regular structure containing octaamino groups can be synthesized , a cage-structured polyγ-aminopropyl silsesquioxane (POSS-NH 2 )as follows.

[0038]

[0039] In the second step, polyγ-aminopropyl silsesquioxane (POSS-NH 2 ), the reactive poly-N methoxy clathrate silsesquioxane (POSS-N(C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com