Antibacterial thermal silk sheet and preparation method thereof

A technology of silk floss and fibroin, applied in degumming, textiles and papermaking, etc., can solve the problems of unsuitable natural silk or hemp, etc., and achieve the effect of improving comprehensive utilization value, strong and rapid heating performance, and good heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

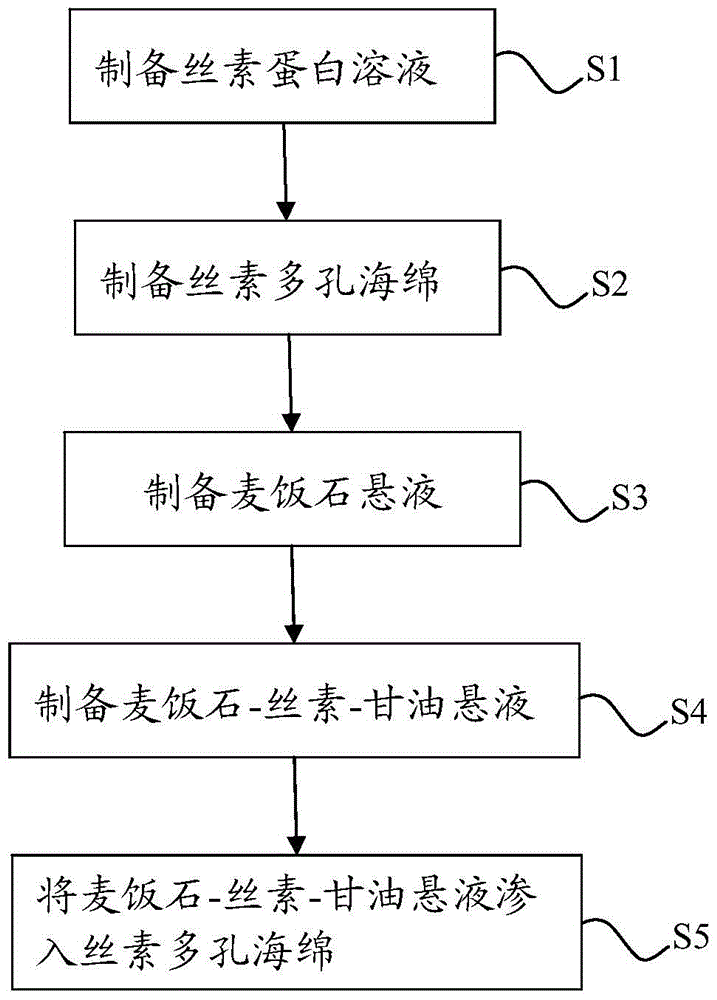

[0038] Such as figure 1 Shown, the preparation method of antibacterial warm silk cotton sheet of the present invention comprises the steps:

[0039] S1. Providing silkworm cocoons, degumming and dissolving them, performing dialysis treatment, and concentrating after filtration to make silk fibroin solution;

[0040] S2. Weigh the silk fibroin solution in part of step S1, add glycerin therein, mix evenly, and freeze-dry under low temperature conditions to obtain a silk fibroin porous sponge;

[0041] S3. Provide medical stone powder, prepare an aqueous suspension of nanoparticles, and perform cationization treatment on the nano medical stone to obtain a cationized nano medical stone aqueous suspension;

[0042] S4. Weighing the silk fibroin solution in part of step S1, adding the same proportion of glycerin and cationized nano medical stones with different gradient mass ratios to obtain medical stone-silk fibroin-glycerol suspension;

[0043] S5. The medical stone-silk fibroi...

Embodiment 1

[0046] Bombyx mori cocoon shells were put into 0.25% sodium carbonate aqueous solution at a bath ratio of 1:50 (g / mL) and boiled three times for 30 minutes, 30 minutes and 45 minutes. Fully cleaned, finally loosened, and dried in an oven at 60°C to obtain degummed silkworm silk fiber.

[0047] Weigh the degummed silkworm silk fibroin and dissolve it in a 45% ethanol solution containing 30% to 40% anhydrous calcium chloride by mass at a bath ratio of 1:10 (g / mL), and dissolve it at 70°C for 2 hours to obtain silkworm silk prime solution.

[0048] Fill the silkworm silk fibroin solution into a dialysis bag with a molecular weight cut-off of 12.0-16.0kDa, place the dialysis bag filled with the silkworm silk fibroin solution in a container filled with deionized water, and replace it with new deionized water every 2 hours. The water in the container was replaced with water, and the dialysis was continued for 3 days to obtain the purified silkworm silk fibroin aqueous solution. Ad...

Embodiment 2

[0053] Bombyx mori cocoon shells were put into 0.25% sodium carbonate aqueous solution at a bath ratio of 1:50 (g / mL) and boiled three times for 30 minutes, 30 minutes and 45 minutes. Fully cleaned, finally loosened, and dried in an oven at 60°C to obtain degummed silkworm silk fibers.

[0054] Weigh the degummed silkworm silk fibroin and dissolve it in a 45% ethanol solution containing 30% to 40% anhydrous calcium chloride by mass at a bath ratio of 1:10 (g / mL), and dissolve it at 70°C for 2 hours to obtain silkworm silk prime solution.

[0055] Fill the silkworm silk fibroin solution into a dialysis bag with a molecular weight cut-off of 12.0-16.0kDa, place the dialysis bag filled with the silkworm silk fibroin solution in a container filled with deionized water, and replace it with new deionized water every 2 hours. The water in the container was replaced with water, and the dialysis was continued for 3 days to obtain the purified silkworm silk fibroin aqueous solution. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com