A kind of machine printing silica gel for pigment printing and its preparation method and application

A paint printing, silica gel technology, applied in dyeing, textile and papermaking, etc., can solve problems such as unfavorable product promotion, slurry failure, screen blockage, etc., to broaden application fields and use processes, extend product shelf life, and extend shelf life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

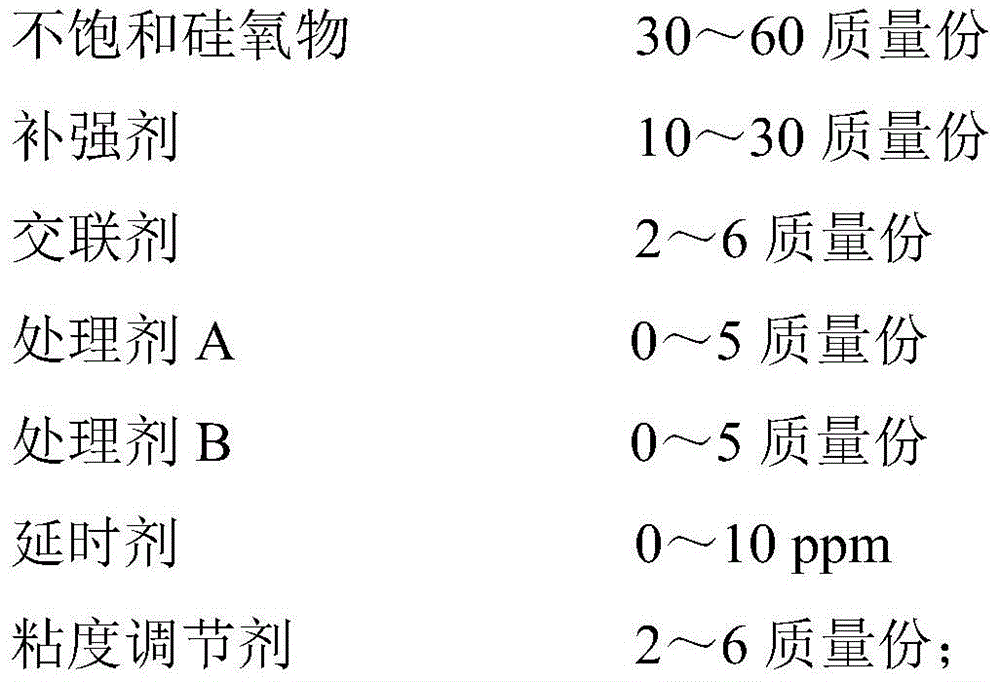

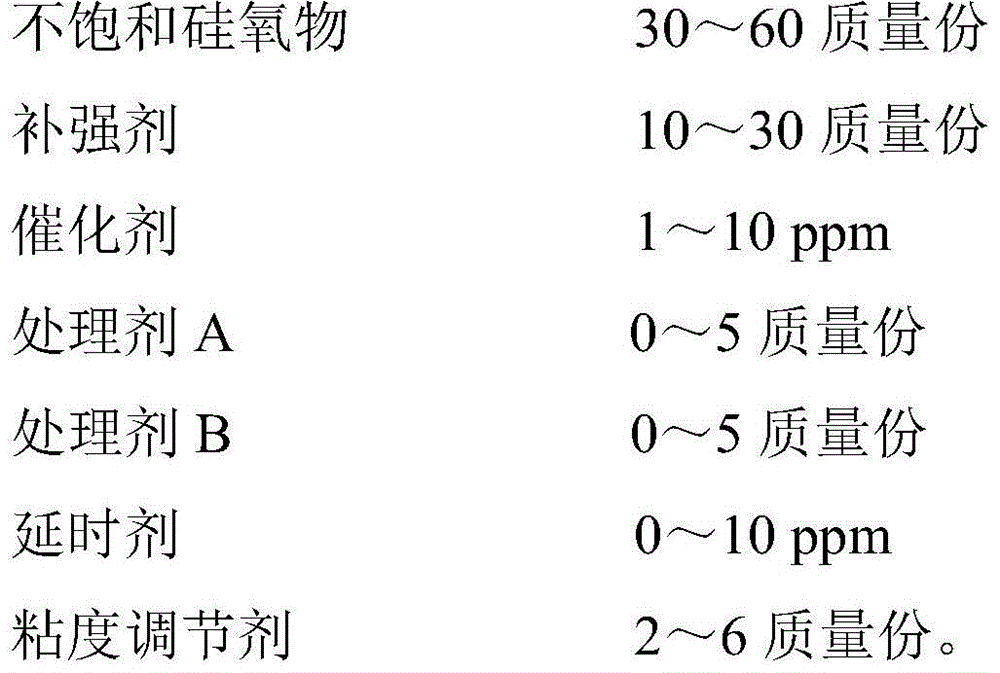

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Preparation of machine-printed silica gel for pigment printing

[0056] Preparation of component A

[0057] Add 60 parts by mass of vinyl polysiloxane (Zhonghao Chenguang Chemical Research Institute Co., Ltd.) with a vinyl content of 0.8% and 5 parts by mass of silica in the mixer. MQ configuration (molecular weight 5000g / mol, vinyl content 5%) vinyl resin (Zhonghao Chenguang Chemical Research Institute Co., Ltd.) 10 parts by mass, hydrogen-containing siloxane with a hydrogen content of 0.8% (Zhejiang Xin'an Chemical Group Co., Ltd. Company) 1.5 parts by mass, 5 ppm of cyclohexynol, 2 parts by mass of water, stirring and dispersing for 2 hours, vacuuming to 0.095 mPa and keeping it for 1 hour, discharging and grinding to obtain component A.

[0058] Preparation of component B

[0059] Add 60 parts by mass of vinyl polysiloxane with a vinyl content of 0.8% and 5 parts by mass of silica in the mixer. MQ configuration (molecular weight 4000g / mol, hydrogen content 0.8%...

Embodiment 2

[0061] Example 2: Preparation of machine-printed silica gel for pigment printing

[0062] Preparation of component A

[0063] Add 60 parts by mass of vinyl polysiloxane with a vinyl content of 0.4% and 10 parts by mass of silica into the mixer. MTQ configuration (vinyl content 3%, molecular weight 6000g / mol) vinyl MQ resin 10 parts by mass (Zhonghao Chenguang Chemical Research Institute Co., Ltd.), 10 parts by mass 2 parts by mass of hexamethyldisilazane, 1 part by mass of 0.8% hydrogen-containing siloxane, 20 ppm of cyclohexynol, 1 part by mass of water, stirred and dispersed for 3 hours, and discharged to obtain component A.

[0064] Preparation of component B

[0065] Add 60 parts by mass of vinyl polysiloxane with a vinyl content of 0.4% and 10 parts by mass of silica into the mixer. MTQ configuration (hydrogen content 0.2%, molecular weight 3000g / mol) hydrogen-containing silicone resin 10 mass parts (Zhonghao Chenguang Chemical Research Institute Co., Ltd.), Speier's catalyst 1...

Embodiment 3

[0067] Example 3: Preparation of machine-printed silica gel for pigment printing

[0068] Preparation of component A

[0069] Add 30 parts by mass of vinyl polysiloxane with a vinyl content of 0.2% and 10 parts by mass of silica in the mixer. MTQ configuration (vinyl content 3%, molecular weight 6000g / mol) 5 parts by mass of vinyl MQ resin, 2.5 parts by mass of hexamethyldisilazane, 0.5 parts by mass of 0.8% hydrogen-containing siloxane, cyclohexynol After 10 ppm, 0.5 parts by mass of water, stir and disperse for 3 hours, and discharge to obtain component A.

[0070] Preparation of component B

[0071] Add 60 parts by mass of vinyl polysiloxane with a vinyl content of 0.2% and 15 parts by mass of silica in the mixer. After 10 ppm of Speier's catalyst, 2 parts by mass of ethyl orthosilicate, and 2 parts by mass of water, the mixture was stirred and dispersed for 2 hours and discharged to obtain component B.

[0072] Mix component A and component B to obtain a machine-printed silica ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com