Active lactobacillus or probiotics heat and convective drying protective agent and preparation method thereof

A technology of active lactic acid bacteria and convection drying, applied in dairy products, milk preparations, applications, etc., can solve problems such as gaps, and achieve the effect of improving residual activity and reducing bacterial damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

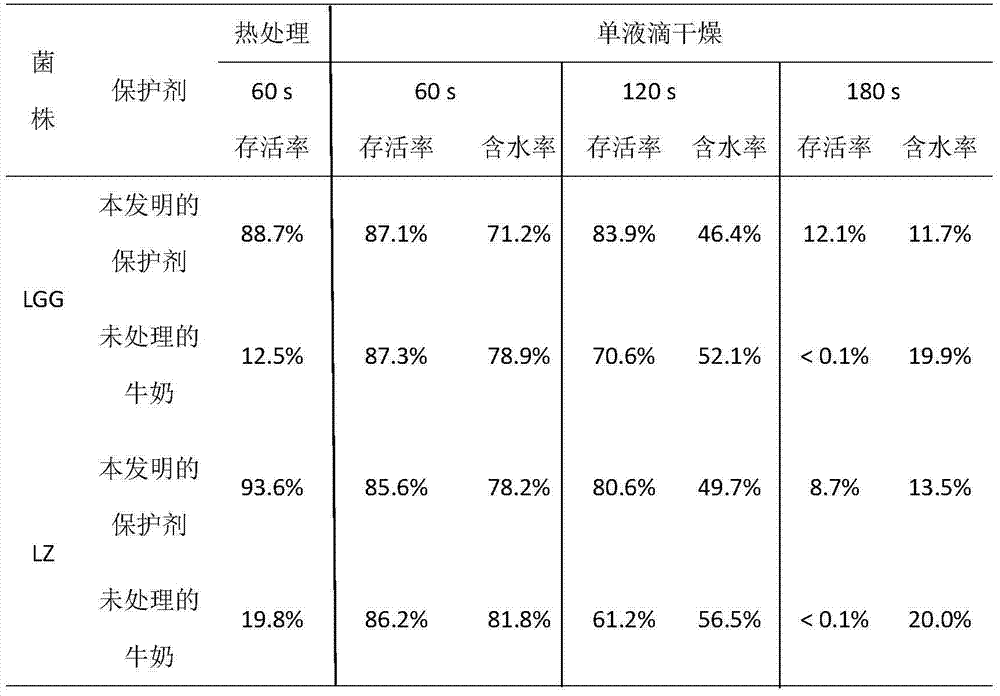

specific Embodiment 1

[0019] Preparation of protective agent: Add 1.1g calcium chloride (approximately equal to 10mmol / L calcium ion) to 100mL milk, stir magnetically at 25°C for 30min, and heat at 60°C for 15min until the milk protein coagulates. The coagulated milk is homogenized to obtain the required protective agent.

[0020] Test strains: Lactobacillus rhamnosus GG (preservation number ATCC53101, hereinafter referred to as LGG, disclosed in patent No. US 4839281 (A)) and Lactobacillus casei Zhang (preservation number CGMCC 1697, hereinafter referred to as LZ, in patent No. CN 101144062A Disclosure), both strains are commercially available.

[0021] Bacterial suspension preparation: the two strains were activated in MRS medium at 37°C for 12 hours, and then cultured in MRS for 24 hours. Centrifuge 1 mL of the fermentation broth of the two strains at 8000 rpm for 15 min, discard the supernatant to collect the bacterial cells. The bacterial cells of the two strains were washed with physiologic...

specific Embodiment 2

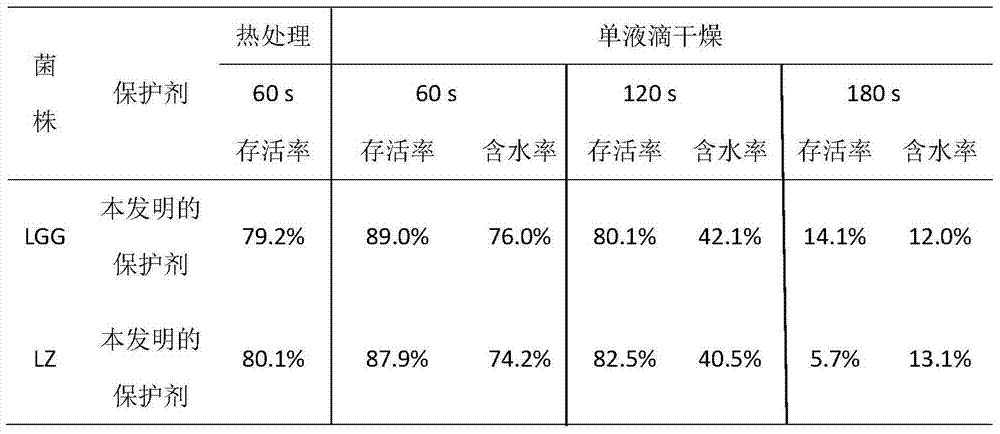

[0028] Specific embodiment 2: add 5.5g calcium chloride (approximately equal to 50mmol / L calcium ion) in 100mL milk, heat 10min under 60 ℃, other operations are the same as specific embodiment 1.

[0029] Table 2. Survival rates of two strains of probiotics after heat treatment and changes in survival rate and moisture content during single droplet convective drying

[0030]

specific Embodiment 3

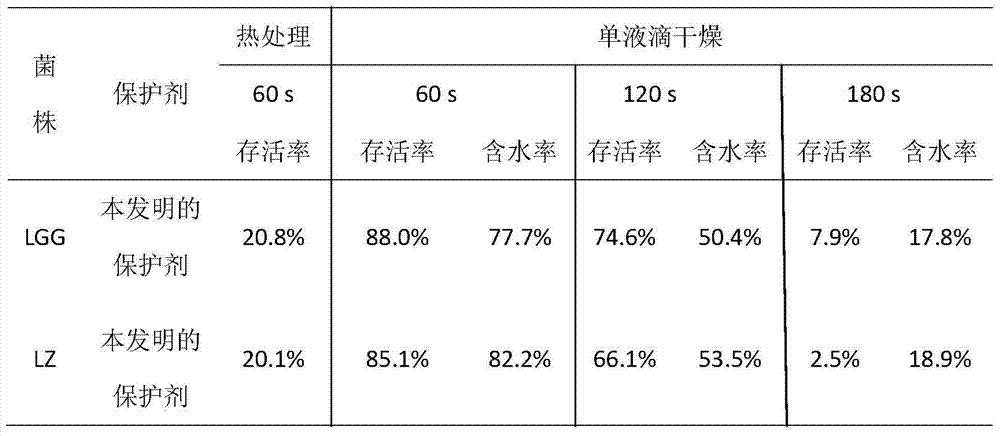

[0031] Specific Example 3: 0.11 g of calcium chloride (approximately equal to 0.1 mmol / L calcium ion) was added to 100 mL of milk, heated at 60° C. for 30 min, and other operations were the same as in Specific Example 1.

[0032] Table 3. The survival rate of two strains of probiotics after heat treatment and the change of survival rate and water content during single droplet convective drying

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com