Splicing process for aluminum outer skin of military shelter

An outer skin, military technology, used in manufacturing tools, metal processing, welding equipment, etc., can solve the problems of easy peeling of the surface paint coating, poor waterproof effect of the cabin, easy deformation and cracking, etc., to prevent the paint coating from falling off. , Improve the connection stability, ensure the effect of flatness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

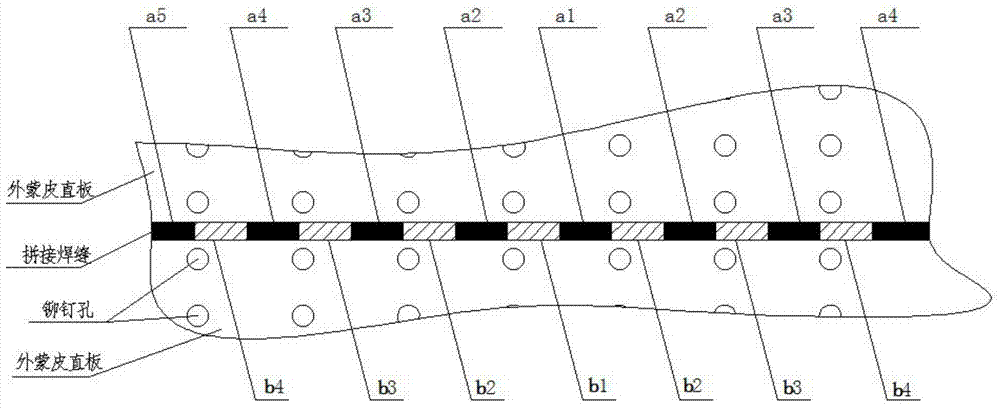

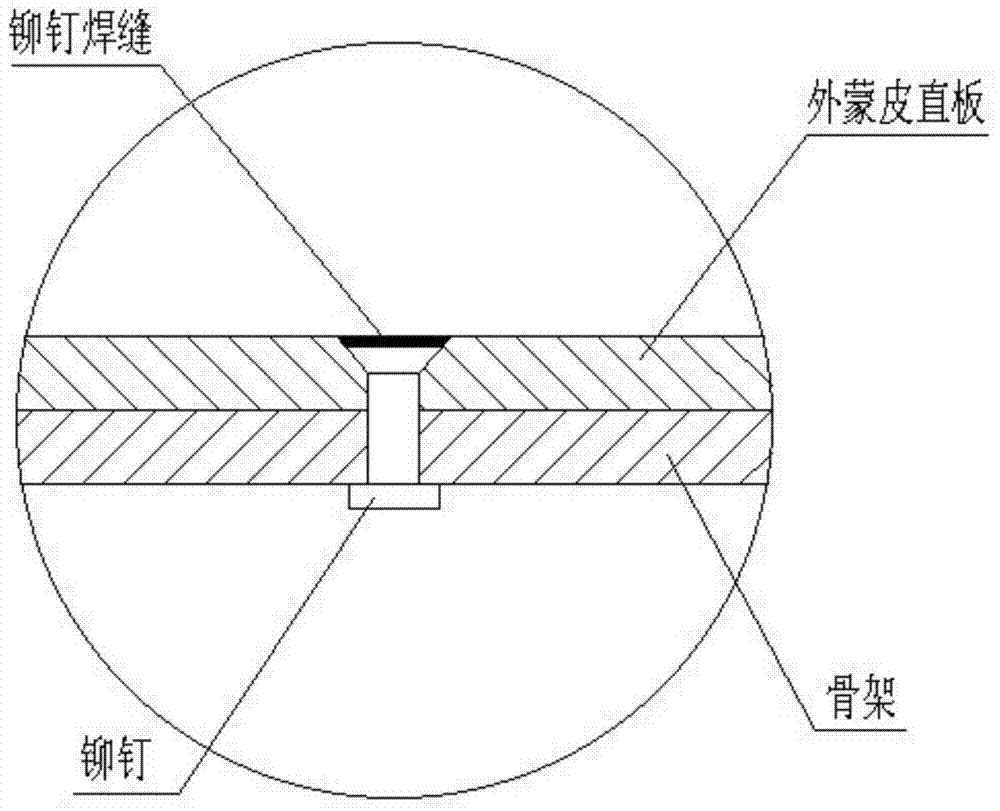

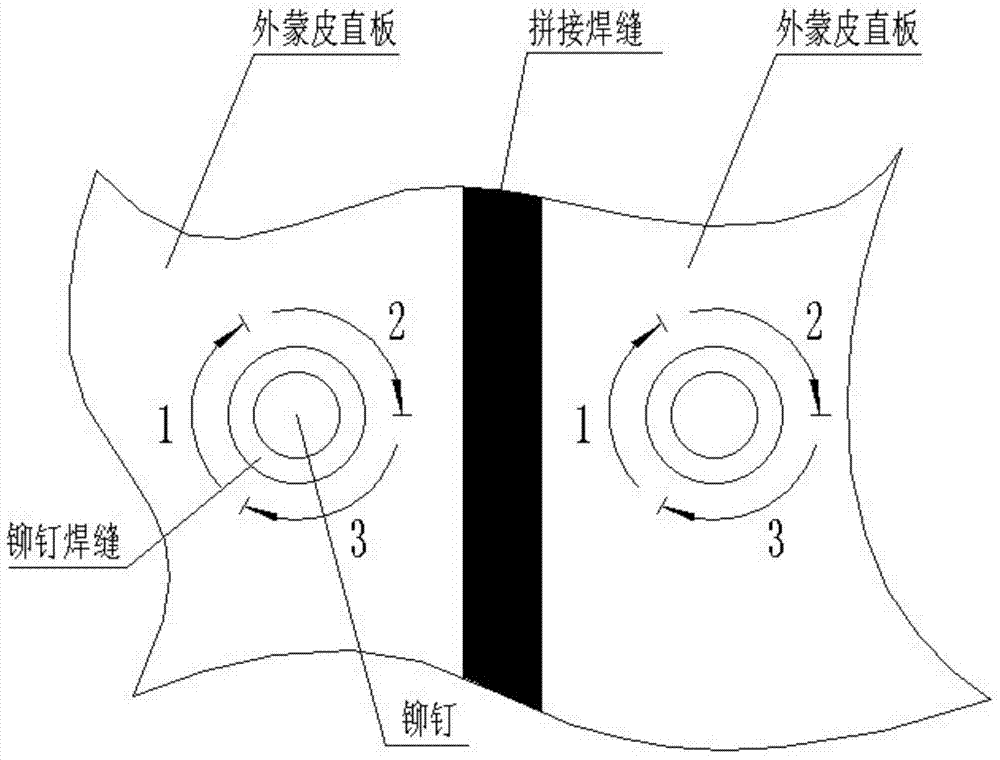

[0035] When it is necessary to splice the aluminum outer skin straight plate on the outer wall of the military shelter cabin, first carry out the skeleton assembly and correction: assemble the skeleton of the shelter that needs to cover the outer skin in place, adjust the position, size and shape of the skeleton; clean up before welding : Use a cleaning solution to clean the surface of the skeleton and the straight outer skin, remove dust and oil, wipe the welds with acetone and gasoline, and clean the oxide film on the surface with a polishing machine; docking positioning: place two straight outer skins that need to be spliced together on the On the frame, ensure that there is a 3mm wide weld seam between the two outer skin straight plates; drill rivet holes: Drill a number of rivet holes evenly arranged in an array on the outer skin straight plate and the frame, and two adjacent rivets in the same row of rivets The spacing between them is 100mm; the spacing between the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com