New biological filter tank process and filter tank

A biofilter and filter technology, applied in the direction of biological treatment devices, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of high water consumption and power consumption for backwashing, difficulty in backwashing of biofilters, Problems such as high frequency of backwashing can achieve the effect of reducing the difficulty of backwashing, reducing the amount of backwashing water, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Structure and technology of the present invention are described as follows:

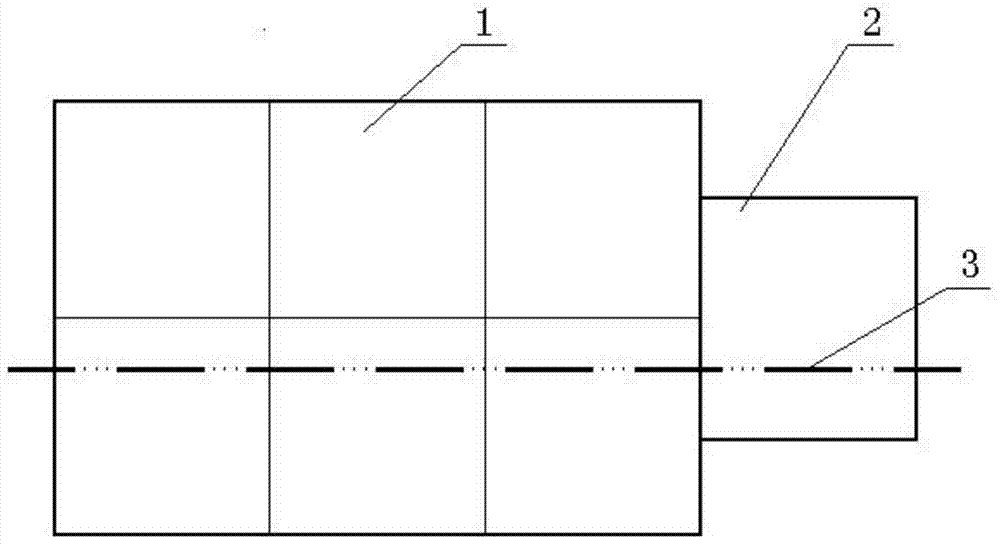

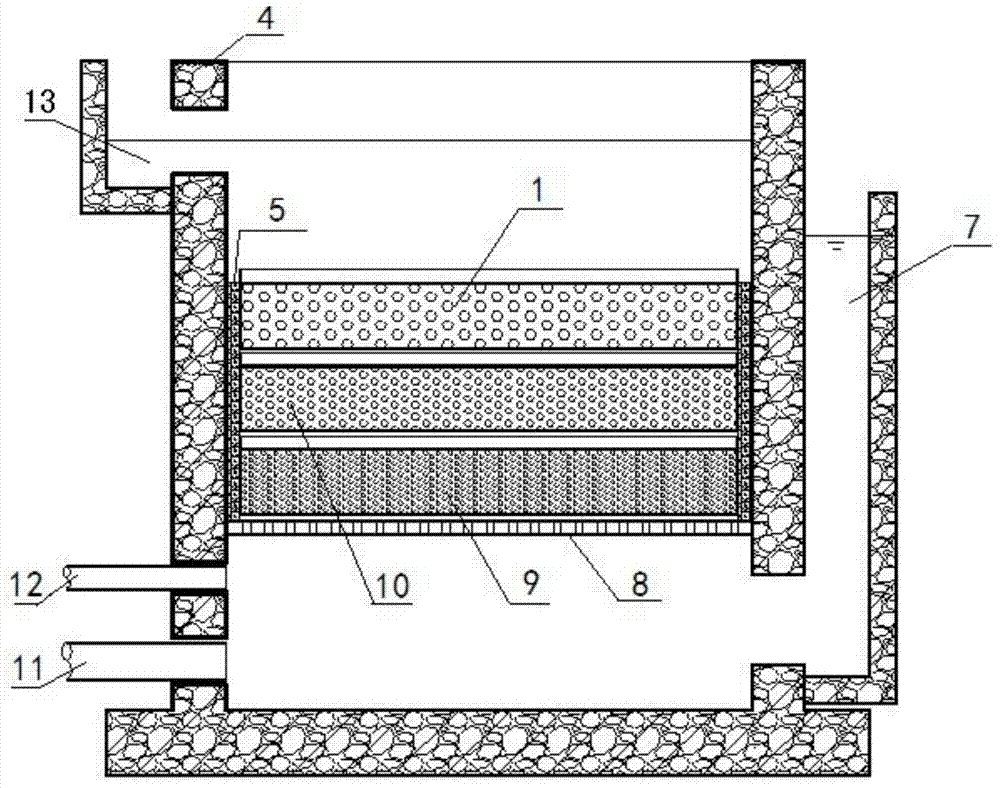

[0019] A type of biofilter process, the biofilter filter material is packed in a hoistable box, and the filter bed is vertically divided into several layers by using the filter material box, that is, the upper layer filter material box 1, the middle layer filter material box 10 and the Lower filter box 9, see figure 2 . see figure 1 , shows a filter tank composed of six filter tank units, and each filter tank unit can also divide the filter bed plane into several grids on the plane according to actual engineering needs. Place large particle size filter material in the upper filter material box 1, place small particle size filter material in the middle filter material box 10, and place the smallest particle size filter material in the lower layer filter material box 9. Adopting the downward flow operation mode, the particle size of the filter material gradually decreases along the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com