Hexavalent chromium reducing agent and preparation method thereof, cement and preparation method thereof

A hexavalent chromium and reducing agent technology, applied in the field of building materials, can solve the problems of poor stability, ineffective effect, and easy oxidation of ferrous sulfate, and achieve good reducing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

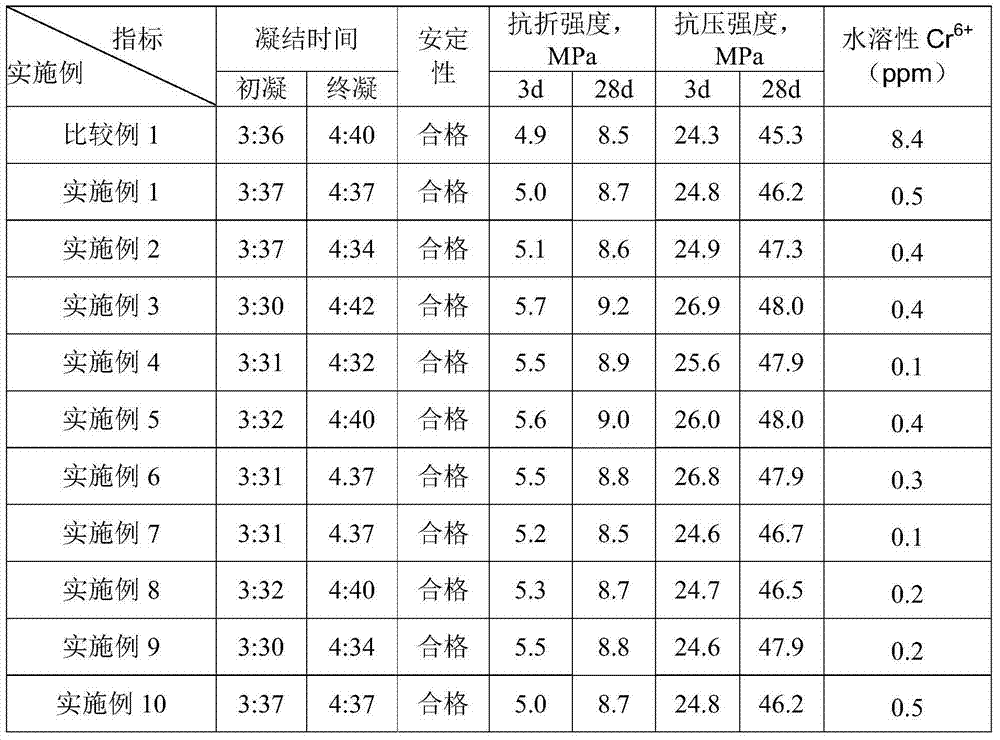

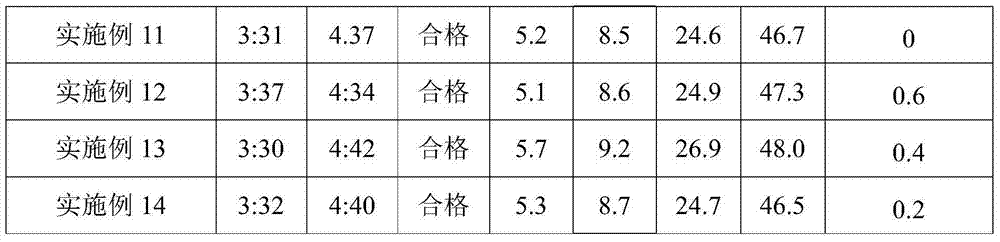

Examples

preparation example Construction

[0033] The embodiment of the present invention provides a kind of preparation method of hexavalent chromium reducing agent, comprises the following steps:

[0034] The raw materials of the hexavalent chromium reducing agent are mixed and ground to obtain the hexavalent chromium reducing agent.

[0035] Wherein, the raw materials of the hexavalent chromium reducing agent include stannous salt for providing stannous ions, ferrous salt for providing ferrous ions and a stabilizer. The stannous salt is counted as stannous ion, the ferrous salt is counted as ferrous ion, and the stabilizer is counted in parts by weight, including the following components: 5-12 parts by weight of stannous ion, 29-59 parts by weight of ferrous ion and 1-5 parts by weight of stabilizer. The added amount of the stabilizer is preferably 3-5 parts by weight.

[0036] The ferrous salt in this step can be one or more in ferrous sulfate, ferrous chloride, ferrous bromide, ferrous hydroxide, ferrous sulfide...

Embodiment 1

[0045] Add 10 parts by weight of stannous sulfate and 80 parts by weight of ferrous sulfate into a mixer and stir evenly, then add 2.5 parts by weight of bentonite, and stir evenly to obtain a hexavalent chromium reducing agent.

[0046] The prepared conventional grade 42.5 cement raw materials were mixed to form a cement batch, and the cement batch was mixed and ground with the hexavalent chromium reducing agent prepared in this example, and prepared into cement according to the cement preparation process of grade 42.5. Wherein, 100 g / t of hexavalent chromium reducing agent is added for every 1 ppm of water-soluble hexavalent chromium ions in the cement batch.

Embodiment 2

[0048] Add 15 parts by weight of stannous sulfate and 100 parts by weight of ferrous sulfate into a mixer and stir evenly, then add 3 parts by weight of sodium lignosulfonate, and stir evenly to obtain a hexavalent chromium reducing agent.

[0049] The prepared conventional grade 42.5 cement raw materials were mixed to form a cement batch, and the cement batch was mixed and ground with the hexavalent chromium reducing agent prepared in this example, and prepared into cement according to the cement preparation process of grade 42.5. Wherein, 100 g / t of hexavalent chromium reducing agent is added for every 1 ppm of hexavalent chromium ions in the cement batch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com