A kind of liznti gyromagnetic ferrite material and preparation method thereof

A technology of gyromagnetic ferrite and main materials, which is applied in the field of LiZnTi gyromagnetic ferrite materials and its preparation, can solve composition segregation, affect LiZnTi ferrite grain growth, magnetic domain reversal microwave modulation, and crystal phase impurity etc. to achieve the effects of high saturation magnetization, low sintering temperature, and low ferromagnetic resonance linewidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

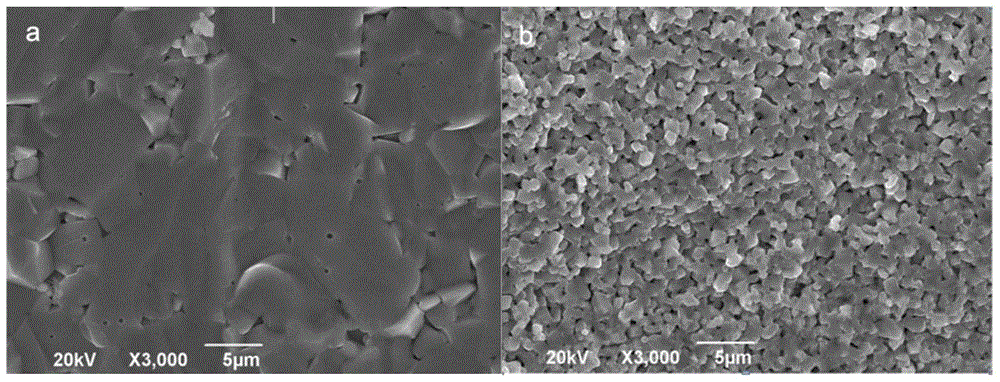

Image

Examples

Embodiment 1

[0018] A preparation method of LiZnTi gyromagnetic ferrite material, comprising the following steps:

[0019] Step 1: Fe 2 o 3 , ZnO, TiO 2 , Li 2 CO 3 as raw material, according to Li 0.43 Zn 0.27 Ti 0.12 Fe 2.18 o 4 The ratio of the molecular formula is weighed, and the main powder is prepared;

[0020] Step 2: Perform a ball mill according to the mass ratio of main powder: water: iron ball = 1:1.2:3. The ball milling time is 4 hours. After taking it out, dry it at 100°C. Put the powder obtained after drying into sintering In the furnace, the temperature was raised from room temperature to 800 °C at a heating rate of 2 °C / min and kept for 1 hour, and then naturally cooled to room temperature with the furnace to obtain the main LiZnTi material;

[0021] Step 3: with BaO, Bi 2 o 3 , B 2 o 3 , Li 2 O, SiO 2 As the raw material, the raw material is according to the mass ratio BaO: Bi 2 o 3 :B 2 o 3 : Li 2 O: SiO 2 = 2:2:2:3:1 ratio of ingredients, wet ball ...

Embodiment 2

[0025] A preparation method of LiZnTi gyromagnetic ferrite material, comprising the following steps:

[0026] Step 1: Fe 2 o 3 , ZnO, TiO 2 , Li 2 CO 3 as raw material, according to Li 0.43 Zn 0.27 Ti 0.12 Fe 2.18 o 4 The ratio of the molecular formula is weighed, and the main powder is prepared;

[0027] Step 2: Perform a ball mill according to the mass ratio of main powder: water: iron ball = 1:1.3:3. The ball milling time is 6 hours. After taking it out, dry it at 100°C. Put the powder obtained after drying into sintering In the furnace, the temperature was raised from room temperature to 820 °C at a heating rate of 2 °C / min and kept for 2 hours, and then naturally cooled to room temperature with the furnace to obtain the main LiZnTi material;

[0028] Step 3: with BaO, Bi 2 o 3 , B 2o 3 , Li 2 O, SiO 2 As the raw material, the raw material is according to the mass ratio BaO: Bi 2 o 3 :B 2 o 3 : Li 2 O: SiO 2 = 2:2:2:3:1 ratio of ingredients, wet ball ...

Embodiment 3

[0032] A preparation method of LiZnTi gyromagnetic ferrite material, comprising the following steps:

[0033] Step 1: Fe 2 o 3 , ZnO, TiO 2 , Li 2 CO 3 as raw material, according to Li 0.43 Zn 0.27 Ti 0.12 Fe 2.18 o 4 The ratio of the molecular formula is weighed, and the main powder is prepared;

[0034] Step 2: Perform a ball mill according to the mass ratio of main powder: water: iron ball = 1:1.4:3. The ball milling time is 8 hours. After taking it out, dry it at 100°C. Put the powder obtained after drying into sintering In the furnace, the temperature was raised from room temperature to 820 °C at a heating rate of 2 °C / min and kept for 3 hours, and then the temperature was naturally lowered to room temperature with the furnace to obtain the main LiZnTi material;

[0035] Step 3: with BaO, Bi 2 o 3 , B 2 o 3 , Li 2 O, SiO 2 As the raw material, the raw material is according to the mass ratio BaO: Bi 2 o 3 :B 2 o 3 : Li 2 O: SiO 2 = 2:2:2:3:1 ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com