Furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin for resin grinding tool and preparation method of furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin

A water-soluble phenolic resin, compound modification technology, used in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problem that water-soluble cannot meet the requirements of resin abrasive mixing operation, low cutting and grinding performance of grinding wheels, and resin grinding quality. Poor stability and other problems, to ensure the uniformity and stability of the spread, the cutting and grinding efficiency is obvious, and the product quality is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

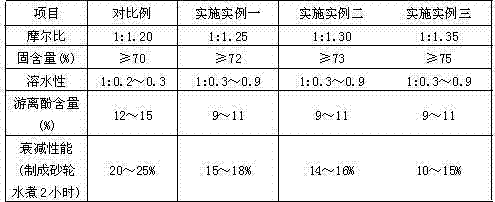

Examples

Embodiment 1

[0030] The water-soluble phenolic resin comprises the following components in parts by mass: 100 parts of phenol; 10 parts of furfuryl alcohol; 120 parts of formaldehyde; 10 parts of urea, 1 part of humectant; 1.2 parts of basic catalyst; share. The concentration of the formaldehyde is 37%, and the molar ratio of the phenol to the formaldehyde is 1:1.2-2. The humectant is methanol, glycol or polyhydric alcohol and the like. The basic catalyst is divalent barium salt, carbonate, calcium hydroxide or sodium hydroxide and the like. The novel coupling agent is a silane coupling agent, such as KH-550, KH-602, KH-590, KH-892 and the like.

[0031] Weigh each raw material according to the above-mentioned ratio of parts by mass, and prepare according to the following steps:

[0032] (1) Add phenol, formaldehyde and 20% to 50% furfuryl alcohol to the reactor;

[0033] (2) Add a basic catalyst to the reactor;

[0034] (3) Heating, so that the material in the reactor is heated slowl...

Embodiment 2

[0040] The water-soluble phenolic resin comprises the following components in parts by mass: 100 parts of phenol; 25 parts of furfuryl alcohol; 150 parts of formaldehyde; 20 parts of urea, 6 parts of humectant; 2 parts of basic catalyst; share. The concentration of the formaldehyde is 37%, and the molar ratio of the phenol to the formaldehyde is 1:1.2-2. The humectant is methanol, glycol or polyhydric alcohol and the like. The basic catalyst is divalent barium salt, carbonate, calcium hydroxide or sodium hydroxide and the like. The novel coupling agent is a silane coupling agent, such as KH-550, KH-602, KH-590, KH-892 and the like.

[0041] Various raw materials were weighed according to the above-mentioned proportions in parts by mass, and prepared with the same process steps as described in Example 1.

Embodiment 3

[0043] The water-soluble phenolic resin comprises the following components in terms of parts by mass: 100 parts of phenol; 35 parts of furfuryl alcohol; 180 parts of formaldehyde; 30 parts of urea, 10 parts of humectant; 3 parts of basic catalyst; share. The concentration of the formaldehyde is 37%, and the molar ratio of the phenol to the formaldehyde is 1:1.2-2. The humectant is methanol, glycol or polyhydric alcohol and the like. The basic catalyst is divalent barium salt, carbonate, calcium hydroxide or sodium hydroxide and the like. The novel coupling agent is a silane coupling agent, such as KH-550, KH-602, KH-590, KH-892 and the like.

[0044] Various raw materials were weighed according to the above-mentioned proportions in parts by mass, and prepared with the same process steps as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com