The preparation method that is rich in papi polyurethane high resilience foam material

A foam material and high-resilience technology, which is applied in the field of preparation of PAPI-rich polyurethane high-resilience foam materials, can solve the problems of environmental and occupational health and safety impacts, poor tear strength, difficulty in reducing density, etc., and achieve soft and hard Reasonable segment distribution, high foaming ratio, good high resilience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is described in further detail.

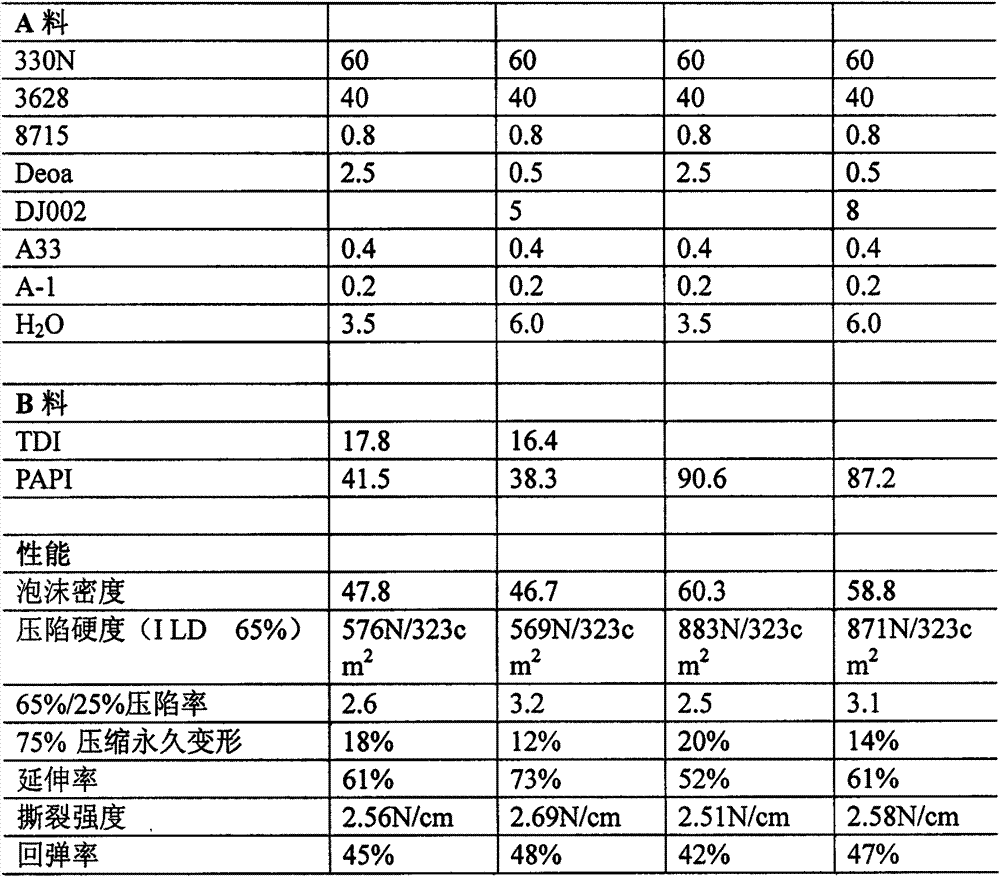

[0012] The preparation method of the PAPI-rich polyurethane high-resilience foam material of the present embodiment comprises the following steps: stirring the A component and the B component respectively in a reaction kettle of a high-pressure foaming agent for at least 1 hour, and heating the foam mold to 50~70℃, and evenly spray the mold release agent on the inner wall of the foam mold, then mix and feed the components A and B into the mold by high pressure of the foaming machine according to the weight ratio of 100:50~70, and the mold is closed and matured for 3~ 8 minutes, then demoulding and trimming in turn to form the finished product; the proportion of component A is: polyether 330N: 33-60%, polymer polyol: 33-60%, silicone oil: 0.5-1.5%, Catalyst A33: 0.2-0.8%, Catalyst A-1: 0.2-0.8%, Diethanolamine as a cross-linking agent: 0.5-3.0%, Polyol additive DJ002: 3-10%, Wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com