Side-thickened polyamic acid film, tape casting equipment and preparation method thereof

A technology of polyamic acid and film, which is applied in the field of polyimide film preparation, can solve the problems of affecting film yield, reducing film production, and wide adjustment range, and achieves the effect of increasing film product yield and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

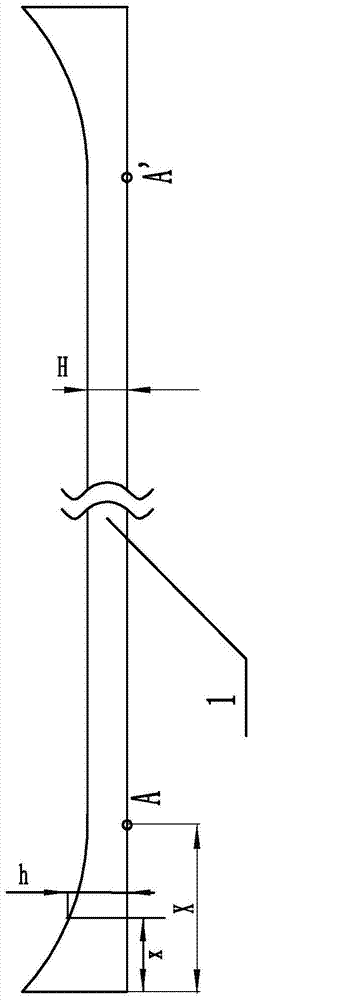

[0037] The drooling equipment of the thickened polyamic acid film in this example includes a molding die, a circulating steel belt carrying the polyamic acid liquid film and a hot air oven. The molding die in this example is a drooling mouth, and the front view of its lip 2 is as follows figure 2 As shown, the opening of the middle part of the lip 2 is W=0.262mm, and the length of the side parts at both ends of the lip 2 is Y=100mm. The opening within the range of 100mm on the side increases gradually as it approaches the outer edge, and the maximum opening at both ends of the lip 2 is 0.574mm. The distance is Y=100mm, the distance between a certain point on the outer side of upper B of the lower edge of lip 2 and the outer end of lip 2 on the same side is y, and the opening degree of lip 2 at this point is w, n=4 in this example,

[0038] w=1.313(Y-y) 4 / 10 9 +0.838(Y-y) 3 / 10 7 +0.975(Y-y) 2 / 10 5 -0.009(Y-y) / 10 3 +0.262.

[0039] The lip 2 opening of the salivating...

Embodiment 2

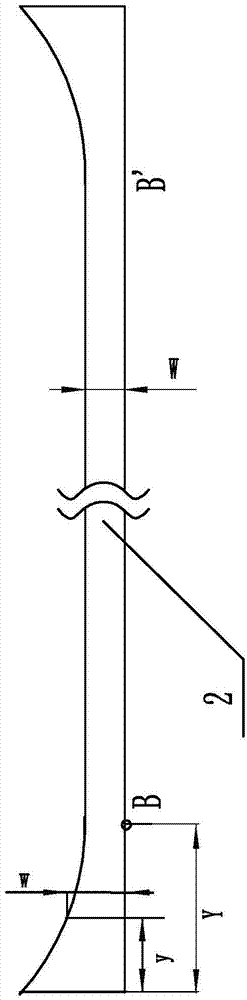

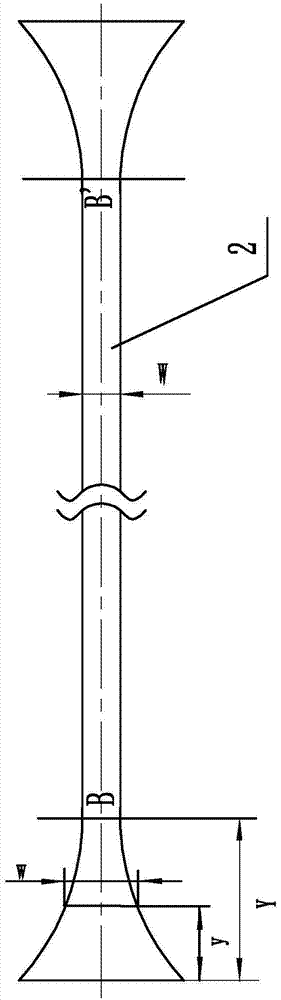

[0041] The molding die in the salivation equipment of the thickened polyamic acid film of this example is an extrusion die head, and the front view of its lip 2 is as follows image 3 As shown, the two ends of the upper edge of the extrusion die lip are upturned, and the two ends of the lower edge are bent downward. The degree of opening gradually increases as it approaches the outer edge, and the maximum opening at both ends of the lip 2 is 0.574mm. Points B and B' are perpendicular to the advancing direction of the steel strip on the front plane of the lip 2, and the distance from the upper and lower edges is equal On the center line of , the distance between points B and B' and the outer end of the same-side lip is Y=100mm, and the distance between a point outside B on the above-mentioned center line and the outer end of the same-side lip 2 is y, and the lip at this point The opening degree of mouth 2 is w, n=4 in this example,

[0042] w=1.313(Y-y) 4 / 10 9 +0.838(Y-y) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com