Multibuffer-harpoon-shift device

A shifting device and flexible cushioning technology, applied in the field of vehicle engineering, can solve the problems of increasing the complexity of shifting device control, long time-consuming synchronization, discontinuity, etc., and achieve the effect of simple structure, fast response speed, and smooth shifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. "Front", "rear", "left", "right", "upper" and "lower" mentioned in the text are all referred to the drawings of this multi-layer buffer insertion and engagement shift device, wherein "front" refers to vertical On the paper face up, "rear" means perpendicular to the paper face down.

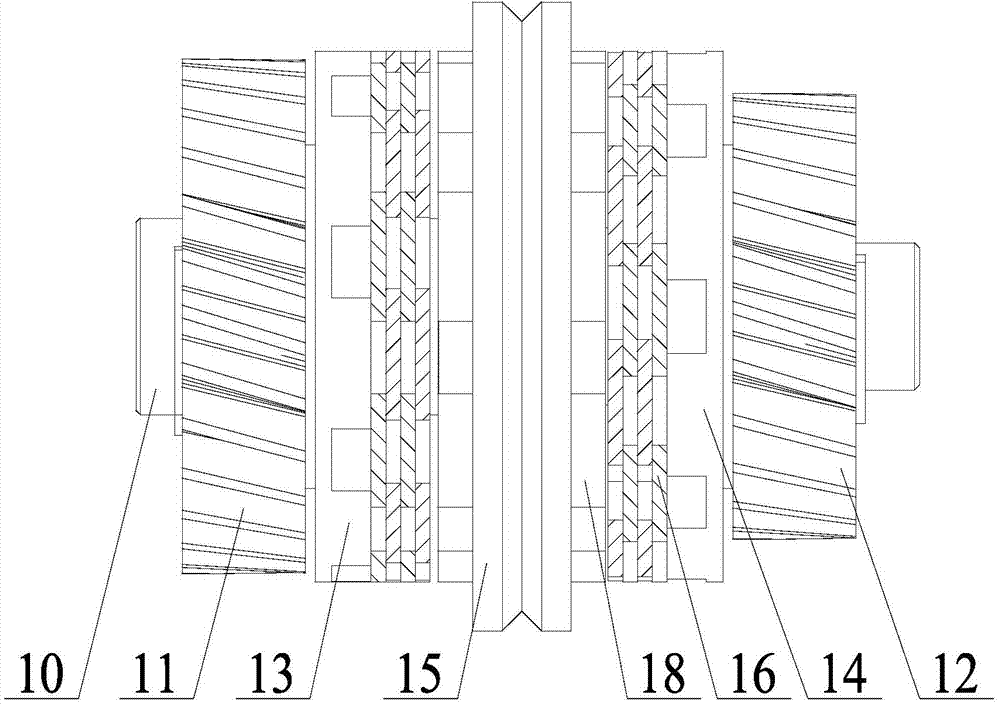

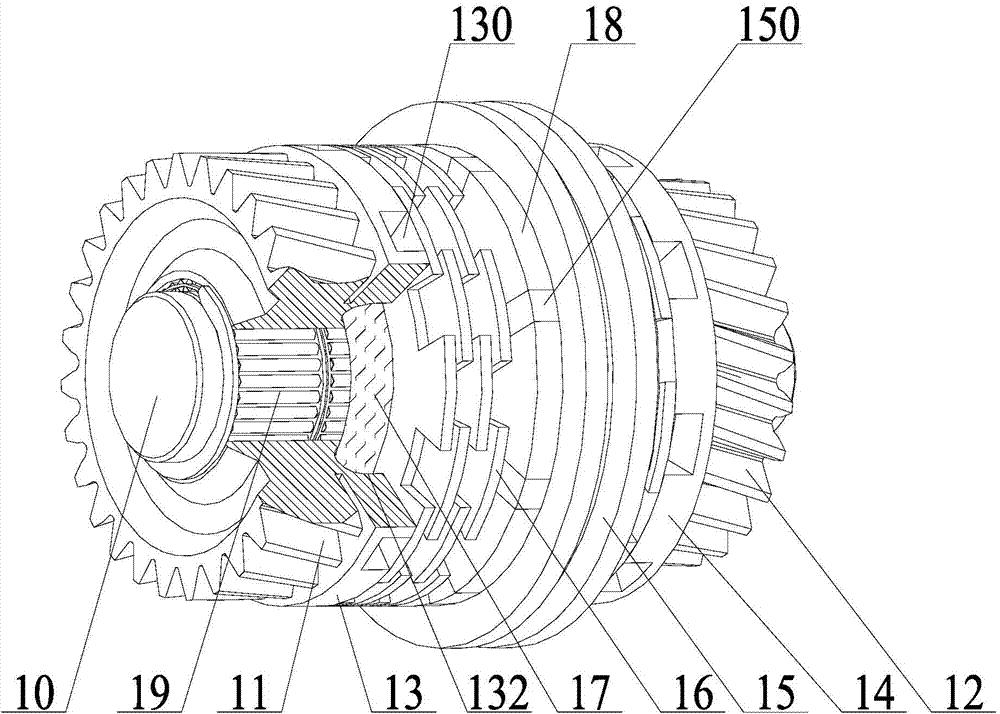

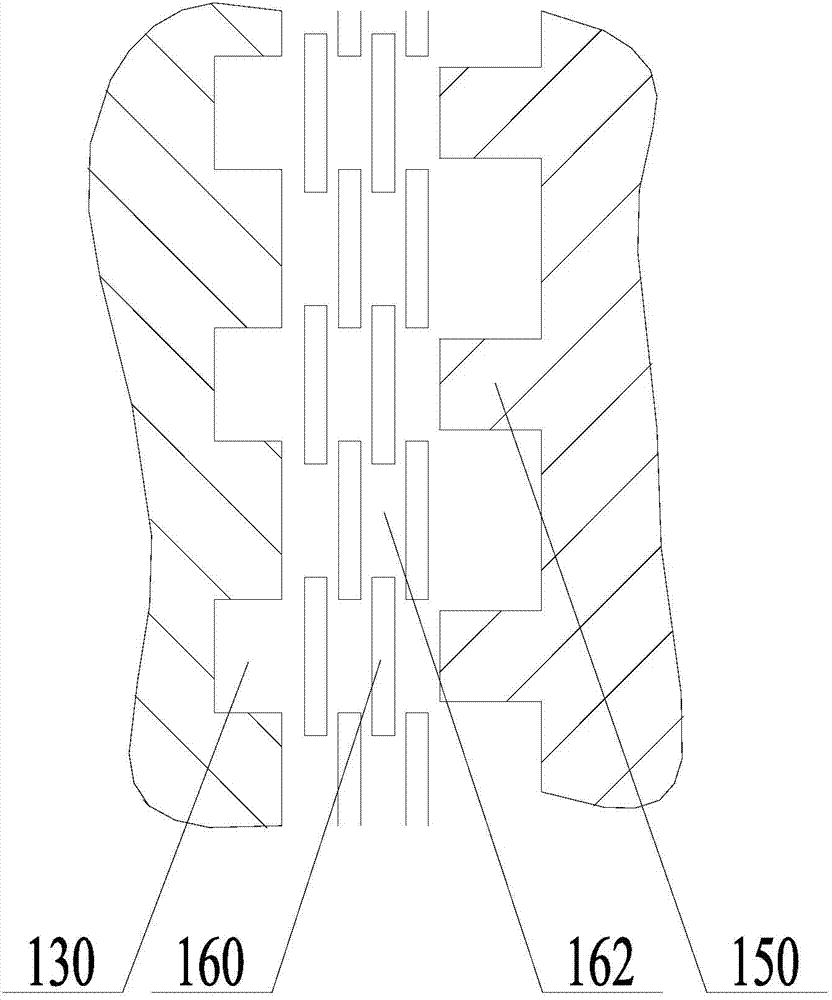

[0028] Such as figure 1 and figure 2 As shown, the rotating shaft 10 is provided with a large gear 11 and a small gear 12 at the same time. The embodiment of the present application provides a multi-layer buffer insertion engagement shift device, the English name is Multibuffer-Harpoon-shift, including: 11 a joint part 13 fixedly connected, a joint part 14 fixedly connected with the pinion 12 , a joint sleeve 15 , a plurality of guide sleeves 16 and a plurality of flexible buffer connection units 17 .

[0029] Wherein, the rotating shaft 10 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com