Modular air source heat pump one-machine pleuripotent energy center

An air source heat pump and energy center technology, which is applied in the direction of refrigerators, mechanical equipment, refrigeration and liquefaction, etc., can solve the problems affecting the beautiful indoor layout, uneven distribution of cold and heat, freezing of water pumps and pipelines, etc., and achieves a compact structure , improved aesthetics, and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

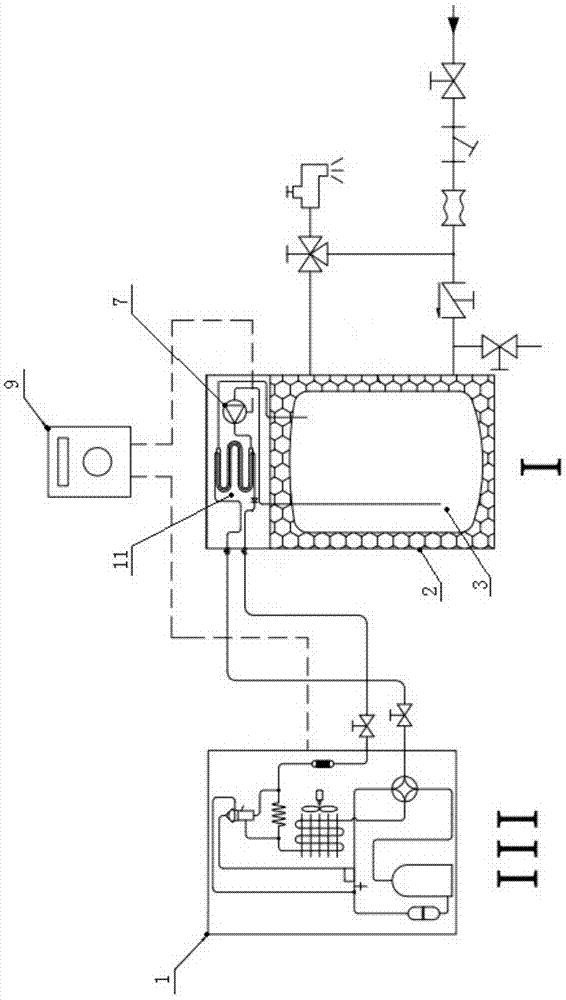

[0031] When the user only needs hot water and connects an air energy external unit 1 outdoors, only the water tank module I and the host module III constitute a hot water system (such as figure 2 shown).

[0032] The specific operation mode is: the hot water circulation pump 7 is turned on, the air energy external unit 1 is turned on, the heat exchanger 11 is used as the high-pressure end of the heating cycle to generate high-temperature and high-pressure refrigerant steam, and the water in the hot water storage tank 3 passes through the hot water After the circulation pump 7 obtains heat from the heat exchanger 11, the water temperature rises to meet the demand for hot water.

Embodiment 2

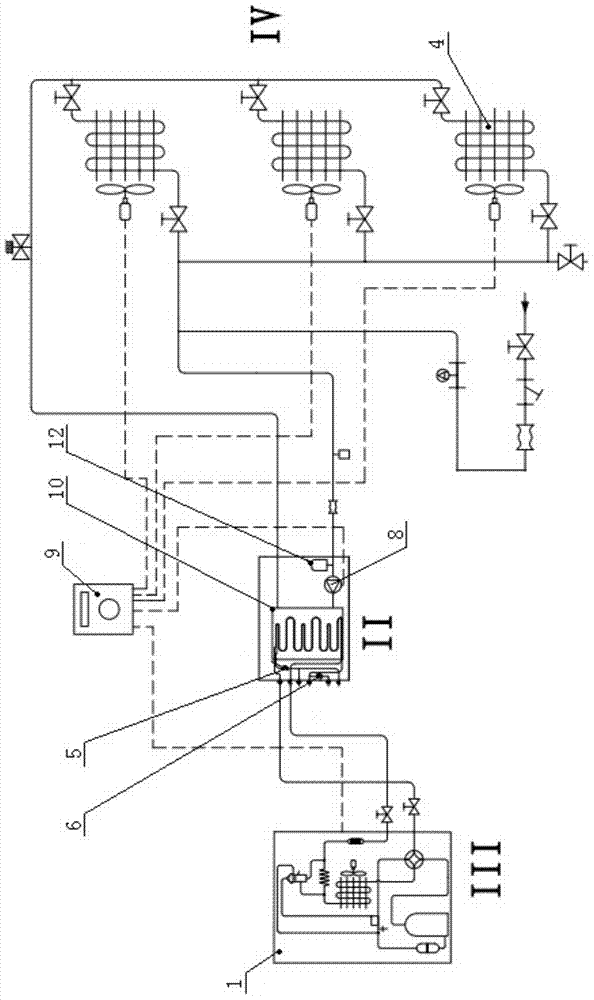

[0034] When the user has a cooling (heating) demand and an air energy external unit 1 is connected outdoors, the cooling / heating system (such as image 3 shown).

[0035] The specific operation mode is: the water supply pump 8 is turned on, the air energy external unit 1 is turned on, the water-cooled heat exchanger 10 is used as the low / high pressure end of the cycle to generate low temperature and low pressure / high temperature and high pressure refrigerant steam, and the heat exchange terminal 4 is driven by the water supply pump 8 The water in the pipeline obtains cold / heat through the water-cooled heat exchanger 10 and releases it to the environment to realize the cooling / heating function. The switching between refrigeration and heating is realized through the reversing of the four-way valve of the air energy external unit 1.

Embodiment 3

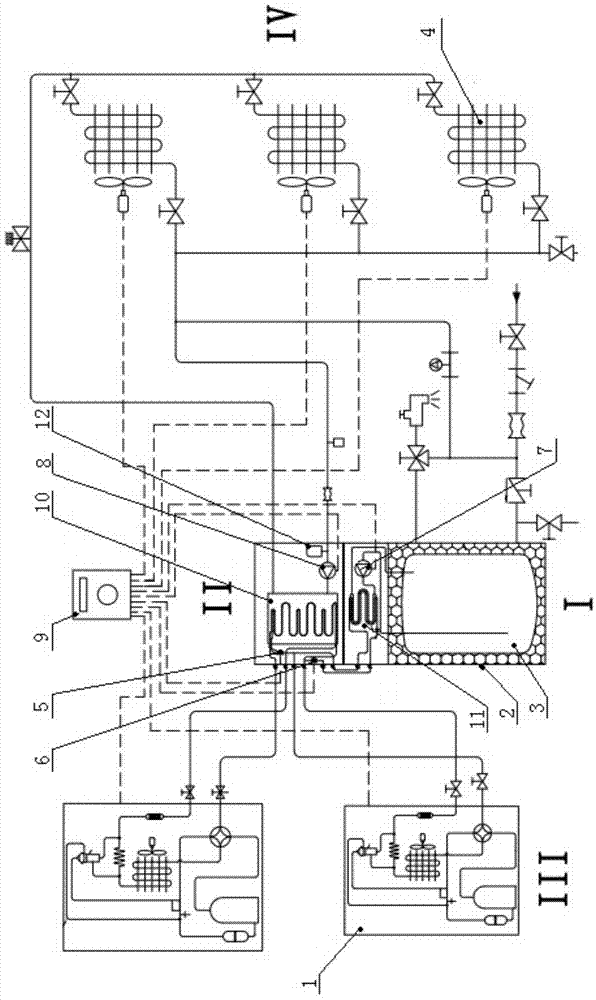

[0037] When the user's apartment size is relatively large, two air energy external units 1 are connected outdoors, namely, air energy external unit 1 and air energy external The system that module IV participates in, the system has five working modes: hot water mode, cooling mode, heating mode, hot water + cooling mode, hot water + heating mode. The hot water heating function and the cooling / heating function are switched through the pipeline solenoid valve A5 and the solenoid valve B6, and the system prioritizes meeting the hot water heating demand.

[0038] 1. When the user only needs to prepare hot water at a set temperature, the water tank module I and the host module III are mainly involved in the operation.

[0039] The specific operation mode is: the hot water circulation pump 7 is turned on, the air energy external unit is turned on to enter the heating mode, the air energy external unit two is closed, the solenoid valve A5 is closed, the solenoid valve B6 is opened, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com