Short-wavelength X-ray diffraction plate-like internal stress fixed-point non-destructive testing method

An internal stress, non-destructive testing technology, used in material analysis, measuring devices, instruments, etc. using wave/particle radiation, which can solve problems such as difficulty in guaranteeing, increasing test errors, and labor and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

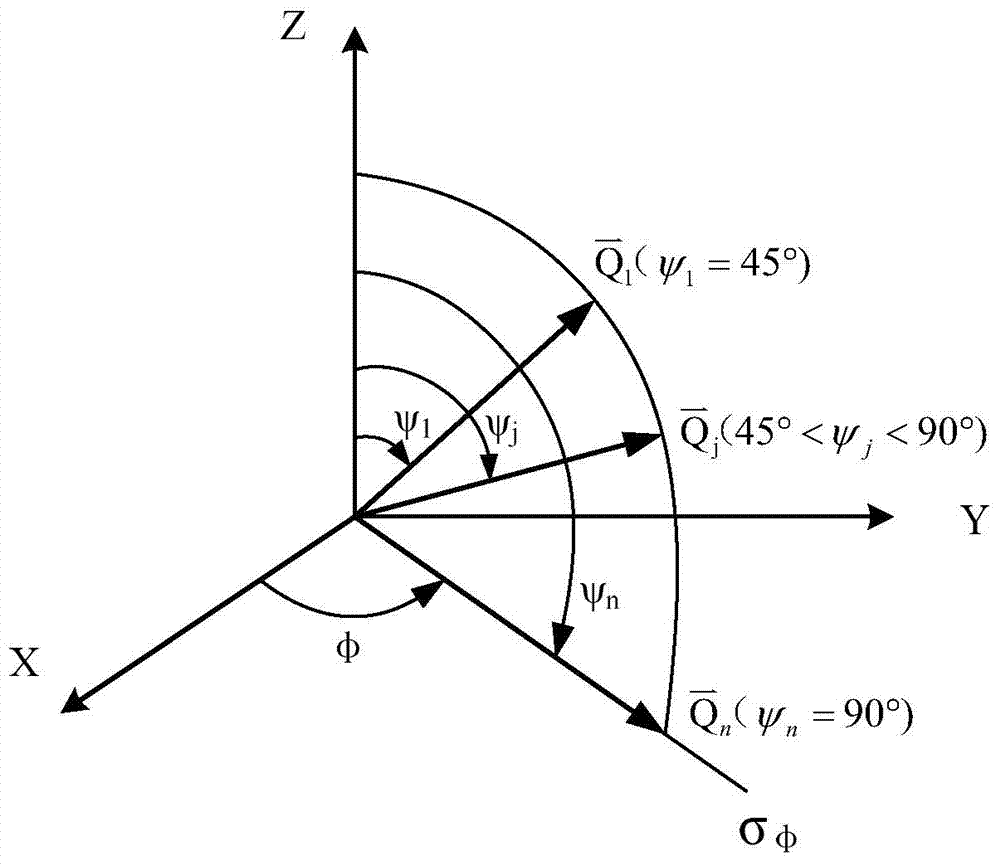

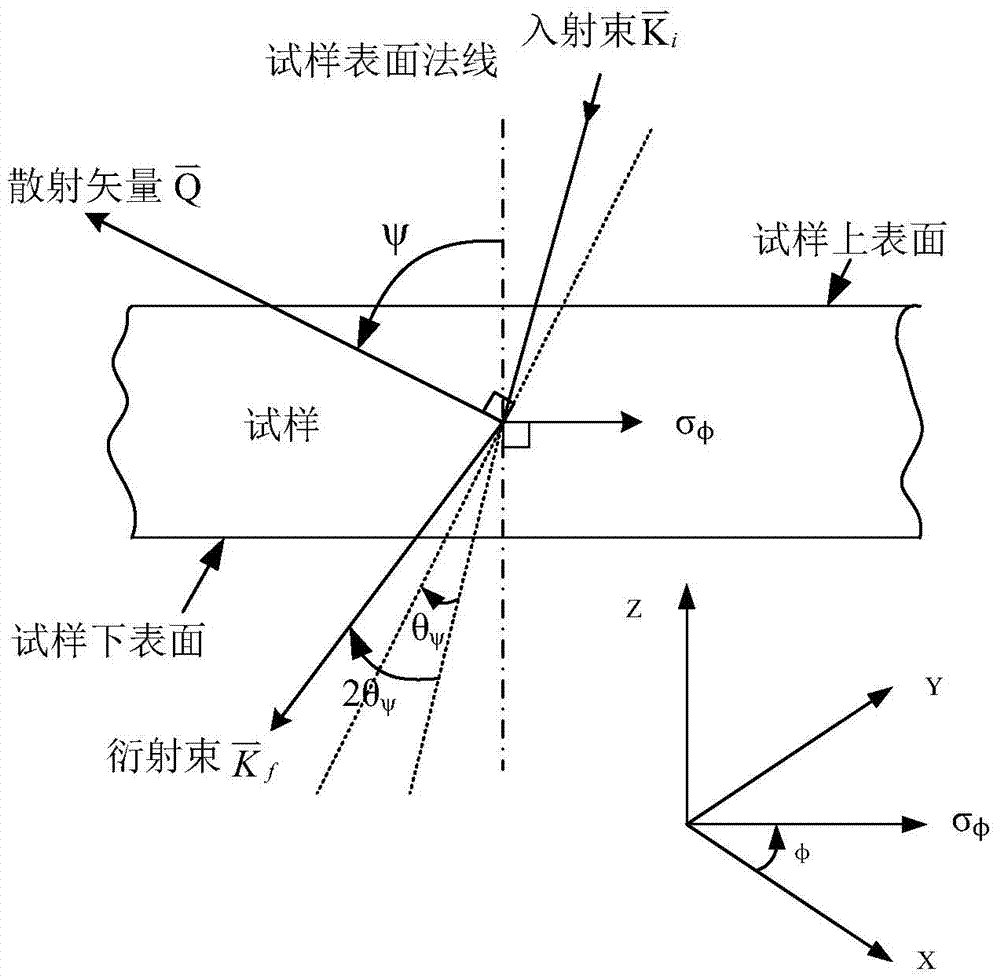

Method used

Image

Examples

Embodiment 1

[0038] The tested sample is a cuboid A100 steel block with a φ=14mm through hole in the middle. Its length is 120mm, its width is 40mm, and its thickness is 2.5mm. In order to improve the fatigue performance, the inner cylinder of the φ=14mm through hole of the sample The surface is processed by strong extrusion, and the prefabricated compressive stress field is used to suppress the fatigue crack growth, and its texture is weak. According to the following method steps, non-destructively detect the radial residual stress at the middle layer of the sample (1.25mm from the upper and lower surfaces respectively) and 4.6mm from the inner cylindrical surface of the through hole:

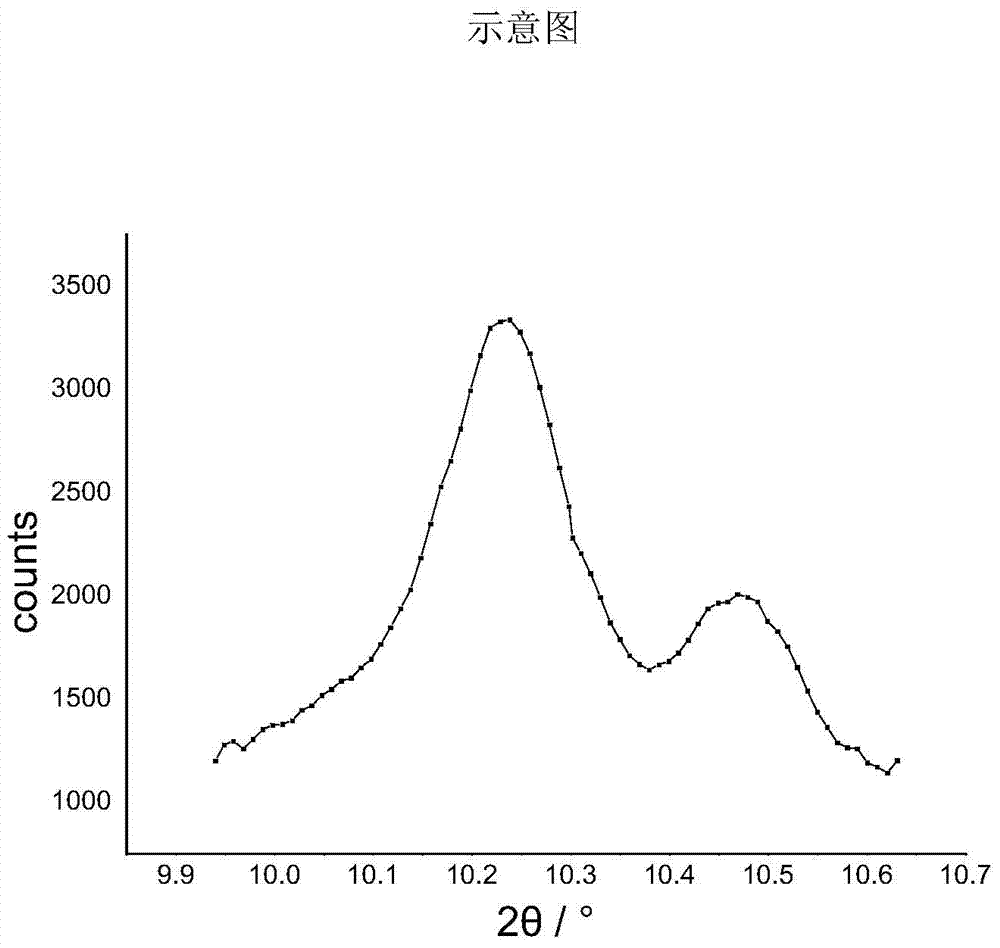

[0039] (1) Select the short-wavelength characteristic X-ray Kα of the heavy metal target X-ray tube used for measurement 1 : According to the short-wavelength characteristic X-ray WKα of the W-target X-ray tube 1 The energy is 59.3kev (corresponding to WKα 1 Wavelength λ=0.0208992nm), WKα 2 The energy i...

specific Embodiment 2

[0056] The tested sample is a friction stir welded part of 2024 aluminum alloy plate with a length of 300mm, a width of 200mm, and a thickness of 6mm. The weld length is 280mm, and the texture of the weld is weak. According to the following method steps, the middle layer of the sample (3 mm from the upper and lower surfaces respectively), the longitudinal residual stress in the center of the weld and its distribution along the length of the weld are tested non-destructively:

[0057] (1) Select the short-wavelength characteristic X-ray Kα of the heavy metal target X-ray tube used for measurement 1 : According to the short-wavelength characteristic X-ray WKα of the W-target X-ray tube 1 The energy is 59.3kev (corresponding to WKα 1 wavelength λ=0.0208992nm), set the upper threshold of the energy analyzer of its X-ray detection and analysis system to be 60.0kev and the lower threshold to be 58.6kev, and its X-ray detection and analysis system will only measure the short-wavelen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com